News & Stories from Romtec Utilities

In lift station controls, HMI stands for “Human Machine Interface” and describes the technology used for an operator to interact with the mechanical and electrical aspects of a lift station system. Romtec Utilities believes that one of the best practices for panel design is to apply a quality HMI on a reliable and flexible programmable logic controller (PLC) platform. Configuring the control panel with an HMI and PLC will give lift station operators access to

Romtec Utilities recently completed start-up services for the Cordata development wastewater lift station in Bellingham, Washington. The City of Bellingham recently increased its charter to incorporate new land for development. The Cordata neighborhood is one of the fastest growing areas. In order to accommodate the speed of this development, Romtec Utilities designed and supplied the complete structural, mechanical, electrical, and on-site support services for this new wastewater lift station, saving the developer time on this

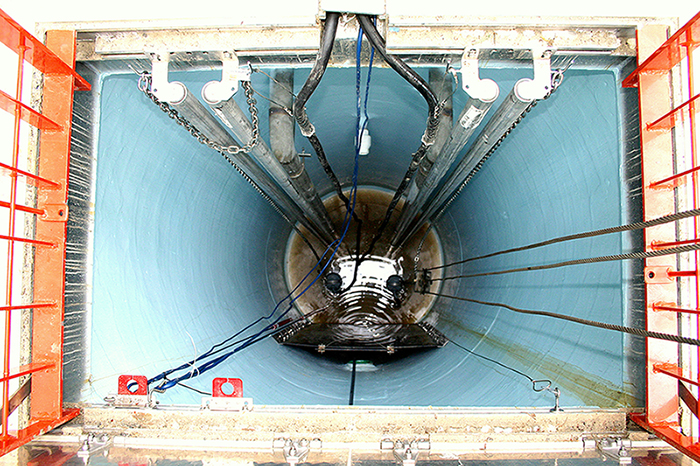

Romtec Utilities fabricates several custom components to correctly mount level sensing devices in pump and lift stations. Level sensors are important devices for the long-term functionality of pumping systems for wastewater, stormwater, clean water, and industrial process water applications. Level sensors trigger the pump of the system to start and stop, and a level sensing failure can lead to a system failure. Romtec Utilities always includes redundant level sensing, but in addition to redundancy, Romtec

Romtec Utilities designs, supplies, and constructs pump and lift stations with all structural, all mechanical, and all electrical and communication systems included. A major aspect of designing systems nationally for all water types in private and public applications is being able to integrate a wide variety of systems and components into a single, engineered pump or lift station. Romtec Utilities has the specific expertise necessary to integrate all types of components into a fully functional

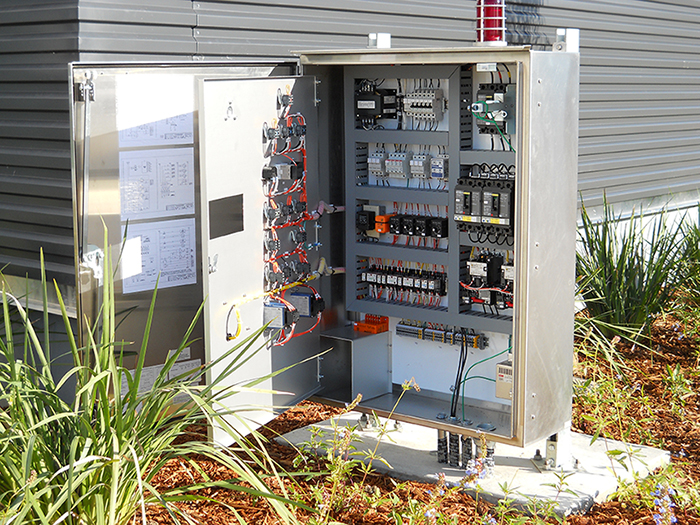

In the past two weeks, this blog has covered safety topics regarding pump and lift stations. The first blog discussed fall protection and how to include safe and reliable hatches on pumping systems with below-grade structural components. Last week’s blog discussed the use safe disconnects for submersible pump cables. This week, we will look at two configurations for pump station electrical controls that meet code requirements and provide a high level of safety for system