Romtec Utilities designs and supplies custom pumping systems to meet the needs of each project, and can supply lift stations, valve vaults, booster stations, and more. Included with the cost of your Romtec Utilities system, our start-up services ensure that our systems are working as designed and ready to be fully commissioned into service.

Lift stations and booster stations have similar components but are fundamentally different when it comes to commissioning. This is in part due to the water type for the system. Lift stations often contain stormwater, wastewater, or industrial water that will be pumped out to be treated, while Booster Stations often supply potable water to residents of a development, like in our Town of Samoa project, or recycled water for irrigation, such as in California’s Purple Pipes featured in the City of Hesperia project.

When commissioning a Booster station into service, Romtec Utilities experts perform duty point testing and intensive PLC programming and take fire flow consideration into account. These tests, programming, and inspections for booster stations can be more intensive and consuming than when commissioning a lift station.

As a part of our start up services, Romtec Utilities performs a “flow” test to ensure that our system is pumping at the “duty point” required. The duty point is the flow of water in gallons per minute at the discharge location. Booster stations have a much higher number of discharge points, such as sinks, toilets, showers, fire hydrants, sprinklers, etc., compared to lift stations that have fewer discharge points that are much easier to access and control. It’s often not feasible to access all the discharge locations for a booster station, so Romtec Utilities performs a “dead head” discharge pressure test at the booster station to verify that the pump is performing as required.

In addition to special considerations for duty point testing, booster stations also require a more intensive PLC programming for the system. Lift stations pump water at a fixed rate, but booster stations pump on demand and will have an ever-changing flow rate. To accommodate the changing flow rate, a closed loop control scheme needs to be implemented to maintain pressure at the discharge of the system. As pressure drops at the discharge locations, the pumps will turn on to maintain pressure. The closed loop control scheme for booster stations requires fine tuning in the field once it is connected to suction and pressure times and can be time intensive to program.

Since booster stations are often servicing new developments, it is important to determine if the booster station supports Fire flow, meaning that the system is supporting the suppression of fire either through sprinklers or fire hydrants. If a system supports Fire Flow, then it also needs to be inspected and tested by the local Fire Marshall to verify proper flow and pressure at the fire suppression locations. Fire flow supporting systems may also require additional testing and training for the National Fire Protection Association 20 rated equipment. This additional testing and training require more time on site to ensure that the booster station will meet the requirements of the local governing entities.

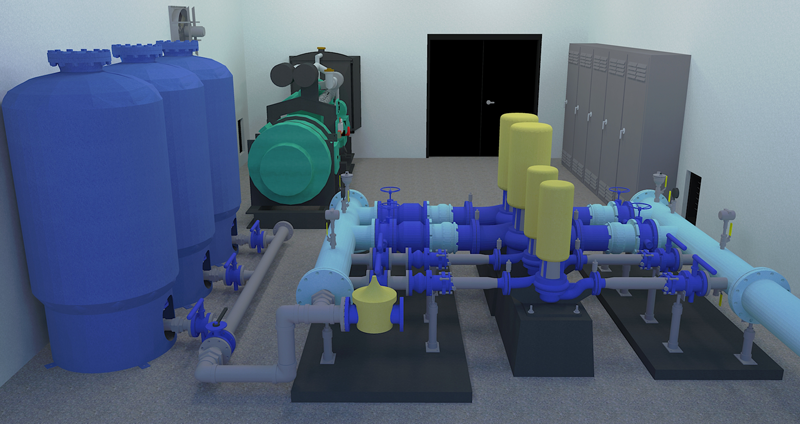

Regardless of the extra requirements to commission a Booster station, Romtec Utilities has the experience and expertise to successfully commission your booster station project. We have supplied booster stations across the nation with control panels, PLC, programming, pipes, and even control buildings supplied by our sister company, Romtec Inc.

In the Town of Samoa project, Romtec Utilities supplied a booster station to serve the mixed-use development of the town. The Town of Samoa Booster station and integrated control building pulls water from an adjacent 165,000-gallon water storage tank and takes both domestic and Fire Flow into account. The station utilizes a closed loop control system that monitors the level/pressure of the supply as well as the level/pressure of the demand. As the discharge pressure decreases (showing an increase in demand) the system will begin to pump. More pumps will turn on as the demand continues to increase, and larger pumps will turn on in the event of a large increase in demand from fire suppression devices.

Booster stations and lift stations can be very complex and incorporate the use of many different devices and components but provide an essential part of our infrastructure and lives. As the population continues to grow and spread farther from water distribution sites, booster stations will be required to ensure that the public has access to clean and safe drinking water. Romtec Utilities has the expertise to design a system to meet all our customer’s needs, design a custom control scheme to operate and maintain the booster station, and perform the field adjustments required based on input from environmental demand.