News & Stories from Romtec Utilities

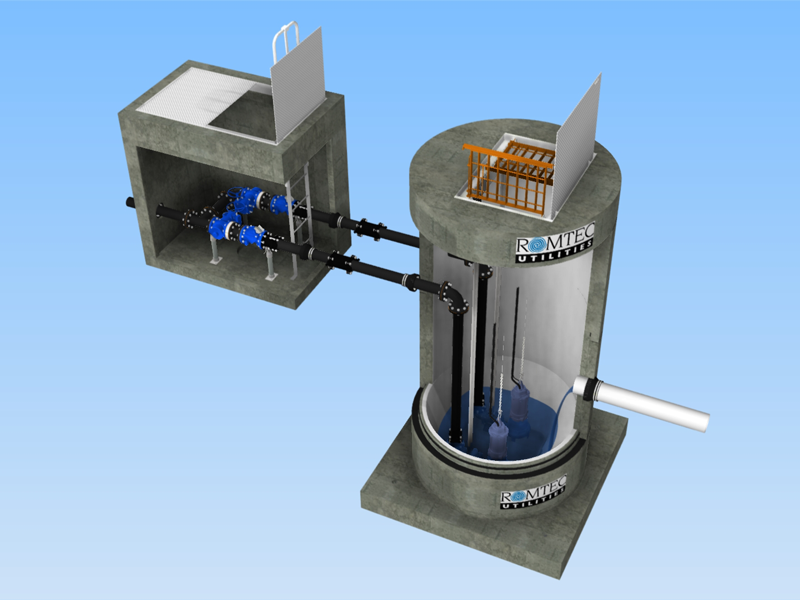

Romtec Utilities designs, engineers, manufactures, and supplies all types of pumping systems for a wide variety of applications. The duplex pump configuration is one of the most common configurations in a pump station design, and it provides owners with several benefits. A duplex configuration means that there are two pumps in the system. Pump stations can also be designed as simplex, triplex, and up to pentaplex configurations, all depending on how many pumps are required

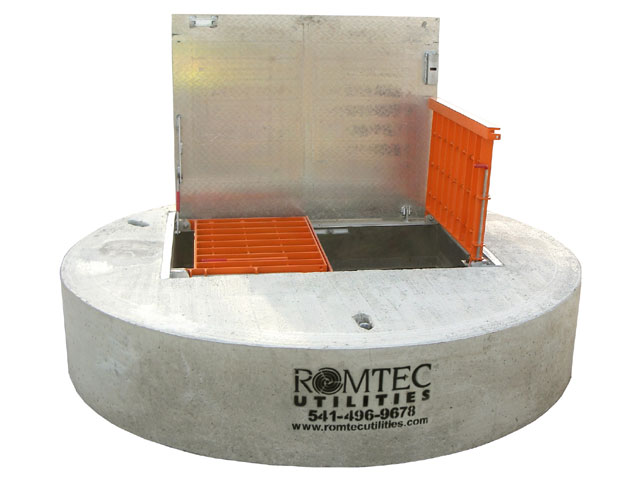

Romtec Utilities engineers complete pumping systems, and the structural components are one of the major assemblies for our systems. On virtually every project, the structural assembly carries a load rating specific to the weight tolerance of the system’s structural components. These ratings apply to the well structures, vault structures, and any access hatches. Hatches, in turn, must be designed in such a way to remain functional and easy to use as well as to meet

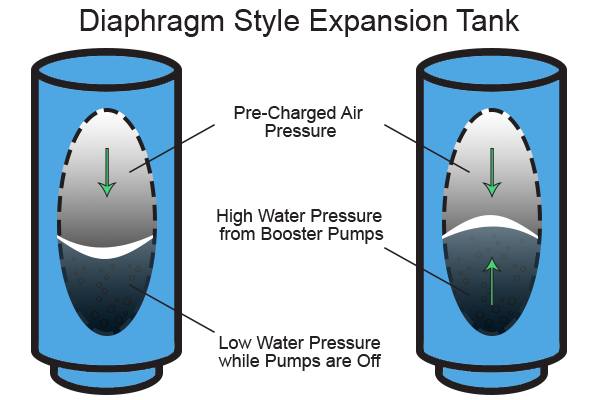

Romtec Utilities designs, engineers, manufactures, and supplies booster pump stations for many types of applications. The commonality between booster pump station applications is the necessity to maintain pressure in a water supply system. The water pressure is maintained for the most part by pumps, either in-line, submersible, or otherwise. Another way that booster pump stations maintain water pressure is through a design component called an expansion tank. Expansion tanks help alleviate the full duty of

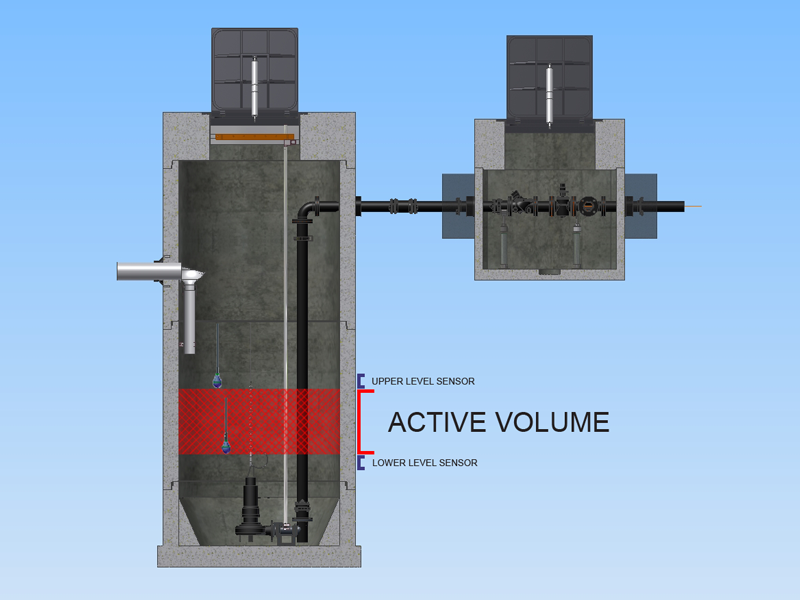

Romtec Utilities designs and supplies pump and lift stations for all types of applications. One key aspect of the pump station engineering is determining the appropriate “active volume” for the pumping system. The active volume describes the volume of water in the well where the pumps are actively pumping. This volume is located between two elevations monitored by level sensors. The top level sensor tells the control panel to cycle a pump on while the

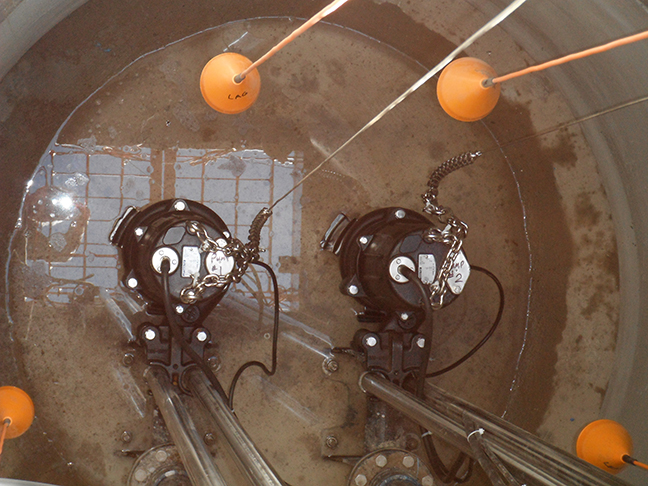

Romtec Utilities commissions each of its pump stations with a start-up technician. The role of this technician is to start the pump station for the first time and to test the functionality of the system to make sure it functions per the system design criteria. One of these tests is called the draw down test. The draw down test is conducted to measure the pumping rate in order to verify that the pumps will operate

Comments 3

I need a quote to replace a duplex sewage pumps in a basement located at a VA Medical facility.

Author

Ejiro, thank you for your comment. Romtec Utilities will be in touch with you shortly.

Are you interested in quoting a 4 inch pump station. At the USCG new London ,CT

We are a Marine contractor if the Boston, Ma area.

cell # 781 264 4748

Thanks