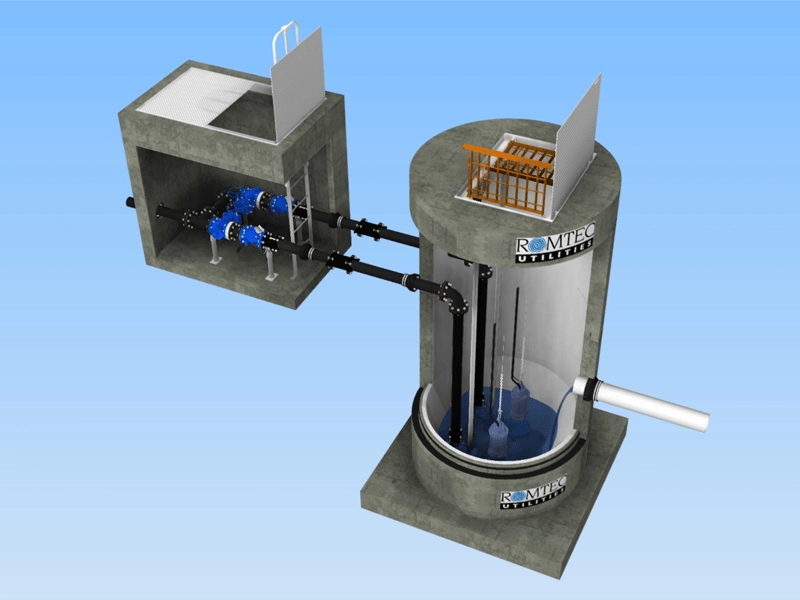

Romtec Utilities designs, engineers, manufactures, and supplies all types of pumping systems for a wide variety of applications. The duplex pump configuration is one of the most common configurations in a pump station design, and it provides owners with several benefits. A duplex configuration means that there are two pumps in the system. Pump stations can also be designed as simplex, triplex, and up to pentaplex configurations, all depending on how many pumps are required to meet the flow requirements. Duplex configurations are often the best engineering solution for wastewater applications.

The first question you might have about a duplex pump station is why two pumps are necessary. The best answer is that there are efficiency and redundancy reasons for using two pumps over one. The efficiency reasons have to do with a typical design requirement for pumping wastewater. This requirement is something called “peaking factor,” and it describes the maximum flow rate that could potentially ever need to be pumped. In wastewater and sewer applications, the “peak flow” needs to be able to be pumped by the lift station even if it never happens. This design requirement is to prevent ever experiencing an overflow scenario.

While designing for a peak flow requirement makes sense, it is, by definition, in extreme excess of the daily flow rates a lift station must pump. If only one pump was used, the pump would need to be very large to meet the peak flow requirements, and it would be extremely inefficient at pumping the lower, “daily” flow requirements. Electrical controls with variable frequency drives, or VFDs, could increase the efficiency to some degree, but this would add cost and complexity. The other option is to meet the peak flow with two pumps.

This is the basic concept of a duplex pump configuration. One pump can be used to handle the daily flow requirements, and if the peak flow is ever experienced, both pumps can be used to reach that pumping rate. Although two pumps will likely cost more than a single large pump, the improvements to pumping efficiency without VFDs makes that margin much slimmer because of the cost of the VFD components and the increased power draw every time the large pump runs.

Efficiency in a duplex configuration applies to more than just power consumption and meeting multiple flow scenarios. It also applies to the wear on the pumps. With two pumps in the pump station, the pumps can cycle between starts. This basically just means that the pumps take turns pumping each time the lift station runs. This drastically reduces wear on the pumps, and it also means that one pump can be pulled out for maintenance, which leads into the next benefit of a duplex configuration.

The other reason for using a duplex pump configuration is redundancy. Avoiding an overflow scenario is the most important aspect of a wastewater lift station. Overflows are as unsanitary as they are unpleasant, and no one wants one. So, what happens if a pump breaks or gets clogged? The best scenario is to have another pump ready to go. This describes redundancy in a duplex lift station configuration.

Duplex lift station configurations are a great solution for wastewater and sewer pumping. In scenarios where there are extreme peaking factors or multiple flow rates, a triplex configuration provides these same benefits but with added capacity. It can seem counterintuitive but designing wastewater lift stations with two pumps instead of one creates a simpler, more efficient, and fully redundant lift station design.

Comments 3

I need a quote to replace a duplex sewage pumps in a basement located at a VA Medical facility.

Author

Ejiro, thank you for your comment. Romtec Utilities will be in touch with you shortly.

Are you interested in quoting a 4 inch pump station. At the USCG new London ,CT

We are a Marine contractor if the Boston, Ma area.

cell # 781 264 4748

Thanks