News & Stories from Romtec Utilities

Romtec Utilities primarily uses two materials for constructing wet wells and sumps: precast concrete and fiberglass. Often, these two materials are preferable to cast-in-place concrete because of the uniform quality, the speed of production, and the cost savings from mass production. These two materials also provide benefits over the other, but choosing one material will typically reflect specific design standards or the requirements of the site. Precast concrete is a very strong and durable material,

Romtec Utilities recently completed a project with the East Bay Municipal Utility District to reclaim water from the San Pablo Water Treatment Plant. This pump station construction is a part of a larger project to bring the water treatment plant back into operation after being decommissioned for several years. The East Bay Municipal Utility District (EBMUD) plans to use the treatment plant to treat water from the nearby San Pablo Reservoir in response to California’s

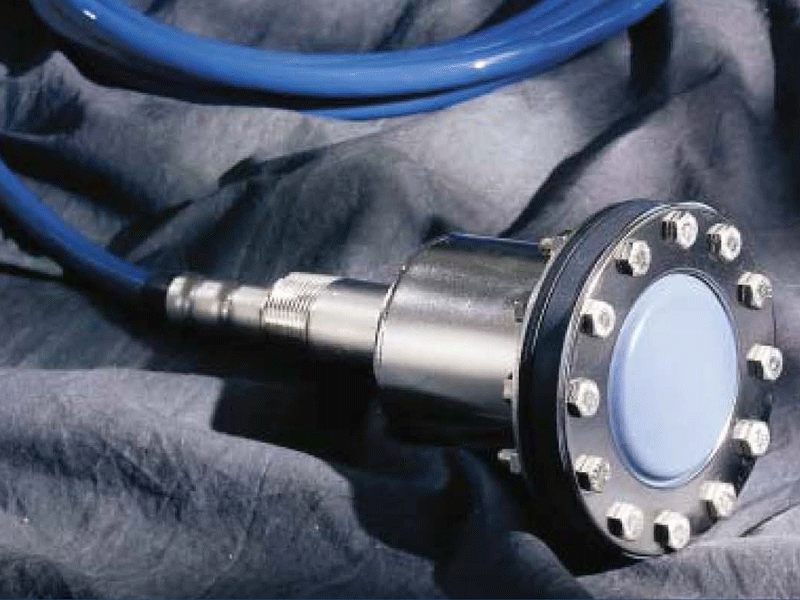

Romtec Utilities designs and supplies pump stations for many different applications, and pressure transducers are a common type of level sensing device available on our systems. Pressure transducers operate by measuring the weight of the fluid in the wet well that is the pressure. The control panel calculates the volume in the well with the pressure readings. This calculation gives a very accurate reading about the water level. Pressure transducers provide pump stations a number

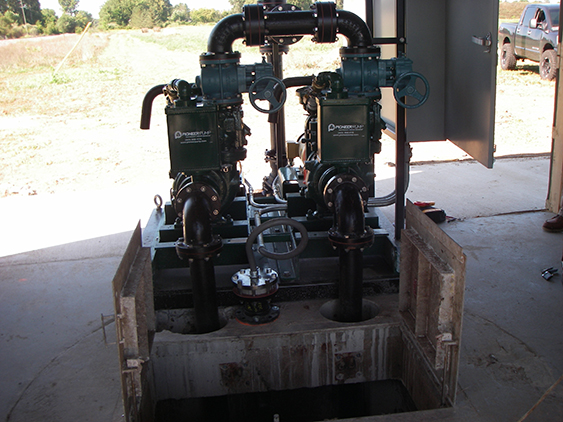

Romtec Utilities offers retrofitting services on pump and lift stations for all types of applications, including wastewater. One common problem with wastewater lift stations is clogging, and this problem can occur for a variety of pretty simple reasons. When clogging occurs too often, it can result in added management costs for lift station owners. This can included shorter pump life, bypass pumping needs, extended personnel time requirements, and many additional costs. As lift station management

Romtec Utilities designs and engineers booster pump stations with fully integrated control buildings for less cost. We have in-house expertise engineering both buildings and pumping systems, making integrated systems a perfect marriage of our capabilities. Romtec Utilities works to sell integrated pumping system packages along with our design services. So we offer our design and engineering work at an extreme discount to potentially win the manufacturing work as well. Cost is just one of many

Comments 2

Pingback: ECONOMY

Pingback: Sig P938 Pistols