Lakehurst Naval Air Station – Low-Cost Sewage Lift Station

Project Description

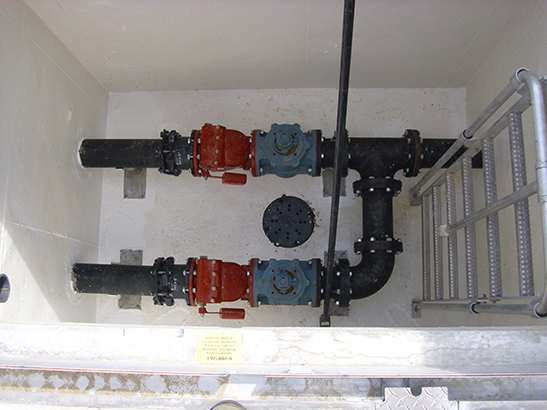

This wastewater lift station was designed to meet the standards of the Lakehurst Naval Air Station while remaining cost effective. A duplex pump configuration utilized submersible 7.5 HP Weil Slicer Pumps to handle suspended solids in the sewage. A UL listed control panel was designed and manufactured in a NEMA 4 enclosure for outdoor operation. Nolta floats were used for the in-well liquid level sensing. The below-grade structural components were designed and supplied precast concrete vaults painted with a marine epoxy exterior coating to prevent moisture incursion.

What Romtec Utilities Provided

- Lift Station Design & Engineering

- Package Lift Station Supplier

- Package Lift Station Manufacturer

- Lift Station Site Plan Layout Designer

- On-Site Lift Station Construction Adviser

- On-Site Start-Up Management

| 250 | 24.77′ |

| GPM | TDH |

Why They Chose Romtec Utilities

Romtec Utilities began this project working with DJs Mechanical out of Millstone Township, NJ. The project was for this new wastewater lift station for the Lakehurst portion of the Joint Base McGuire-Dix-Lakehurst near Trenton, NJ. Romtec Utilities also worked with the site engineer, Pennoni Associates. Garden State Precast supplied the concrete components of the lift station to reduce the cost of the project for the Naval Air Station. Romtec Utilities was selected for the design and supply of this lift station based on the ability to reduce the overall cost of the system. Romtec Utilities also was able to offer complete on-site services for Lakehurst including start-up, testing, training, and a complete system warranty.