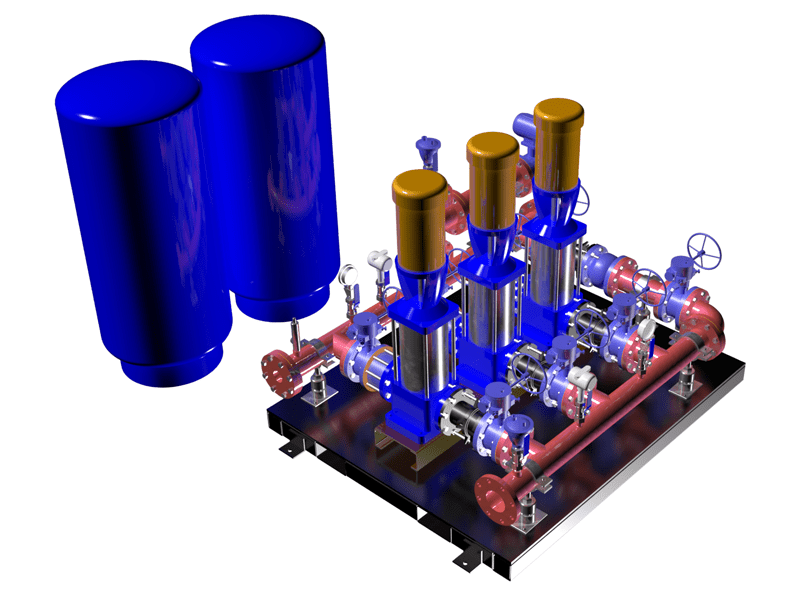

Romtec Utilities designs, engineers, manufactures, and supplies booster pump stations for many types of applications. The commonality between booster pump station applications is the necessity to maintain pressure in a water supply system. The water pressure is maintained for the most part by pumps, either in-line, submersible, or otherwise. Another way that booster pump stations maintain water pressure is through a design component called an expansion tank. Expansion tanks help alleviate the full duty of maintaining pressure by taking some of the requirement off of the pumps, and they also provide additional system performance benefits.

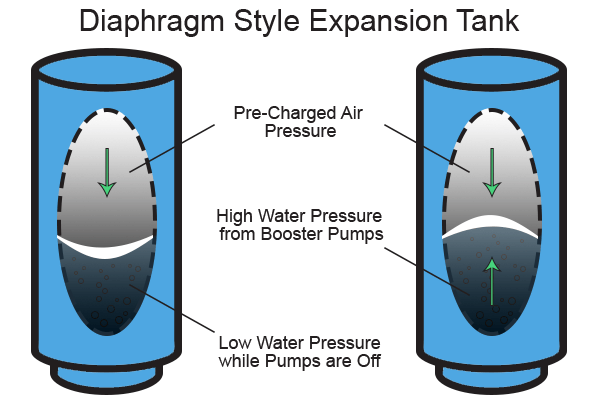

Pumps today are much more robust than they ever have been, but they still wear down, require maintenance, and eventually fail. The lifespan of a pump can be dramatically improved by simply reducing its operation time and/or its frequency. For a booster pump station, the way to accomplish this is through an expansion tank. As the pumps operate, pressure is added to the downstream water system. A portion of this pressurized water is pumped into an expansion tank. Using pressurized air, the expansion tank pushes against the incoming pressurized water. Expansion tanks can function with a bladder or a diaphragm to separate the water from the compressed air or there can even be no barrier in some applications.

As the water is pumped into the expansion tank, the pressurized water “pushes” against the compressed air until the pressure stabilizes at the acceptable level for the system. When the water pressure reaches the desires pressure, the pump or pumps can shut off. This reduces the operation time. Water in the upstream system is still under pressure from the compressed air as opposed to the centrifugal pressure generated by the pumps. This allows water to be used from the system at the acceptable pressure. The pumps will start again when the water in the expansion tank is depleted and the pressure in the system drops.

In addition to alleviating the full duty from the pumps, the expansion tank helps with the performance of the booster pump station. For example, let’s say there is a heavy draw on water, like several showers and sprinklers operating in the hours before a workday. The pump or pumps will be operating full bore to meet the pressure demands. If during this time a valve is closed or a substantial number of outlets are shut off at the same time, the pressure in the system will spike. For a brief moment the pumps will be pumping against for a low pressure scenario that suddenly becomes a high pressure scenario. This can cause all types of negative affects to the system, including a water hammer.

The booster pump station expansion tank acts as the flexible point in the system in this scenario, so the pressure will spike in the tank first. This allows the compressed air to “yield” to the pressure spike while the pumps shut down or slow down. This prevents a wide-variety of problems such as valves and seals failing. The expansion tank also provides a consistent counter pressure during pump operation. Water being used from the system causes variable pressure conditions. The expansion tank creates fairly consistent head pressure by using compressed air to “react” to varying pressure conditions. This allows the pumps to operate within a nominal range, improving pressure consistency in the upstream system.

The primary reason for choosing a specific tank size is the flow and pressure of the booster pump station. Expansion tanks can be engineered as a single large tank or through multiple smaller tanks. This depends on the physical space limitations in the building or room where it is located. These simple devices are great components for improving the functionality and long-term performance of a booster pump station. With Romtec Utilities, you can get these components engineered and integrated into a fully functional control building for a complete booster pump station solution.