Industrial Pumping Solutions That Perform

We design, manufacture and install industrial pumping systems in the US, engineered to handle any fluid type, chemistry, temperature, or flow condition your facility demands.

Systems Built Around Your Needs

We’re an industrial pumps systems manufacturer that specializes in delivering custom-engineered industrial pumping solutions for all applications, from oil and gas to power generation, chemical manufacturing, food processing and more.

Our industrial pumping systems are designed to meet your operational needs and scale with you, no matter how big or small your operations are. Simply tell us how the ideal pump station can improve your operations and our experienced technicians will design and install a durable and reliable system that performs.

Experienced Team

Our team consists of experienced engineers and technicians, ready to lead your project from design to installation.

Backed By A Warranty

Our pumping systems are covered by a standard one -year warranty and lifetime support, so you get the most out of your investment.

For Every Industrial Need

We design pumping systems to handle any water type, chemistry, temperature, or flow condition your facility demands.

For Every Application, There’s A Romtec Industrial Pumping Solution

Our industrial pump and water conveyance systems are built to meet you where you are, so you can keep your critical processes moving.

Sewer & Wastewater Pumps

Remove industrial effluent, sludge, and high-solid waste safely and efficiently.

Stormwater Pumps

Remove floodwater or runoff from your facility quickly to prevent downtime.

Process Pumps

Transfer process fluids with specific temperature or chemical tolerances.

Cooling Water Pumps

Keep critical equipment at safe operating temperature ranges.

Chemical-Handling Pumps

Safely move corrosive or hazardous liquids without contamination.

Choose Your Flow Capacity Range

We give you the freedom to choose a flow capacity that aligns with the size, scope and complexity of your industrial pumping needs.

Low Flow

(5–50 GPM)

For small-scale process operations or isolated facility flows.

Medium Flow

(50–400 GPM)

For mid-sized industrial plants, power stations, and reuse systems.

High Flow

(400–1,500 GPM)

For large industrial facilities or combined storm and wastewater systems.

Super-High Flow

(1,500–10,000 GPM)

For very large industrial sites, bulk water transfer, and municipal-scale treatments.

Pump Anything, Across Any Distance

- Process Water Pumping

- Hot Water Pumping

- Water Reuse Pumping

- Glycol Pumping

- Oily Water Pumping

- Detention Pond Pumping

- Industrial Runoff Pumping

- Acidic Water Pumping

- Caustic Water Pumping

- Pumping Hazardous Materials

- Water Reclamation Systems

Multiple Pump Configurations

Choose a setup that best suits your flow requirements and your backup pumping needs.

Simplex

Single-pump setup for low flow or backup applications.

Duplex

Two pumps for alternating duty and built-in redundancy.

Triplex

Best suited for higher flows or when extra redundancy is needed.

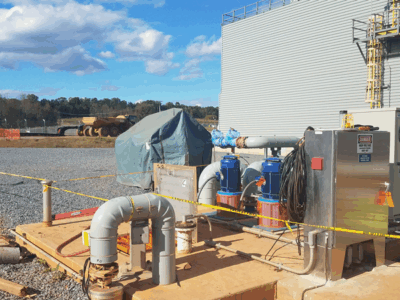

Wet-Dry

Placed above water to simplify routine maintenance and repairs.

Split-Case

For high-capacity, long-service-life pumping in large plants.

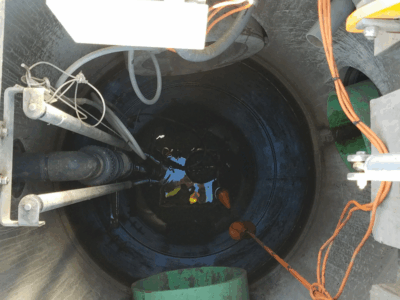

Submersible

Perfect for designs where space maximization counts.

Grinder/Chopper

To break down solids in wastewater and prevent clogs.

Turbine

For deep well or high-head pumping in industrial reuse.

Custom Engineered Components

Our technicians ensure each industrial package pump system is configured with the right materials, mechanical parts and integrated control systems for your needs.

Structural Components

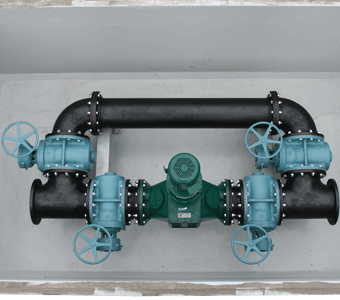

We design robust and corrosion-resistant structures that support your industrial pumping solution and stand the test of time.

- Concrete Wet Wells

- Fiberglass Wet Wells

- Epoxy Coatings & PVC Liners

- Prefabricated Valve & Meter Vaults

- Custom Buildings or Shelters

Mechanical Components

Our industrial pumping solution engineers will work with you to select pumps and mechanical parts that work best for you.

- Centrifugal Submersible Pumps

- Self-Priming Pumps

- Vertical Wet Well Pumps

- Axial Flow Pumps

- Vertical Turbine Pumps

- Jockey Pumps

- Traffic-Rated Hatches

Electrical & Control System Components

We equip your industrial pumping system with the right electrical and control system components for seamless integration.

- UL-Listed Panels with PLC/HMI

- Variable Frequency Drives (VFDs)

- Soft Starters

- Level Sensors (Ultrasonic, Radar, Floats)

- Generators & ATS

- SCADA & Telemetry Integration

Advanced Telemetry To Keep Your Pumping System In Check

Our telemetry and monitoring systems provide real-time performance tracking, early fault detection, and remote system control, making them ideal for facilities where fast response to faults is non-negotiable.

Whether your operation includes multiple industrial pump stations across large sites or remote locations, we configure telemetry options ranging from simple alarms to robust two-way communications, including SCADA integration and cellular or fiber optic connectivity.

Upgrading Your Pumping Capacity?

We’ll integrate new industrial pumps systems and into your existing infrastructure. Our engineering team works closely with your staff and engineers to ensure seamless compatibility with your existing systems, smooth startup, and efficient long-term operation.

We Offer Full Project Lifestyle Support

From the moment you reach out to us until your industrial pump system is up and running smoothly, Romtec Utilities supports you through every phase of your project lifecycle.

Engineering

Our experienced engineers are experts in water conveyance. They will handle everything from preliminary designs and cost estimates to submittal reviews and technical documentation and deliver an industrial pump system aligned with your budget and timeline, ready for approval and installation.

Project Support

Once the design is approved, we’ll assign a dedicated project manager who handles everything from permits and procurement to scheduling and communicating with all parties involved, making them a single contact point for all your needs. This ensures your project stays on track and is delivered on time and within your budget.

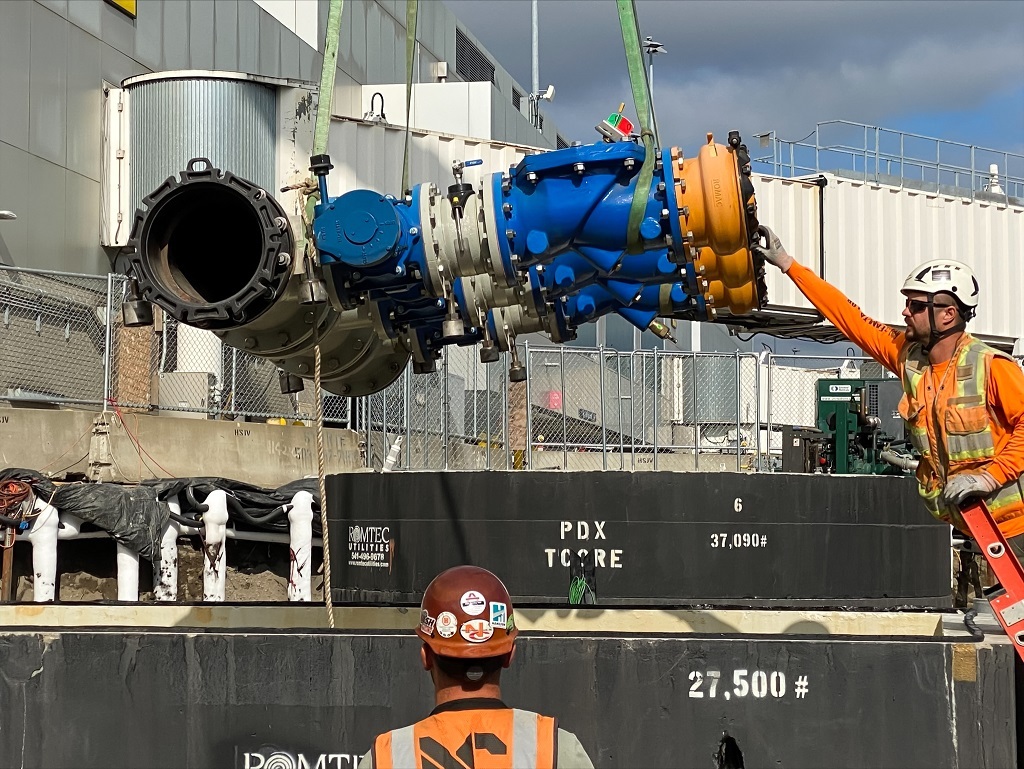

Manufacturing

We prefabricate your industrial pump system and deliver it to the job site to cut down your construction costs and reduce installation time by days and even weeks. The best part? We follow a stringent quality control process to ensure your system was built right and that it functions as it should on the job site.

Construction

Our experienced construction advisors work in close collaboration with your installers on-site and guide them through every stage of assembly, pump system installation and integration. With us by your side, you can rest assured knowing your system is installed correctly, safely and works the way it was designed to.

Commissioning

After your industrial pump system installation, our industrial pumping solution technicians will perform a thorough test of your system, from start-up and control system checks to ensuring everything is running smoothly. We’ll also train your maintenance team so they know how to operate and maintain your new system from day one.

You’re In Good Hands, We’ve Served Industry Leaders

Take a look at our case studies to discover how we as a leading industrial pump systems manufacturer

engineer solutions that keep your operations moving forward.

Ready To Get Started?

Our engineers and technicians are ready to design and install a custom industrial pumping system for your operations. Tell us your requirements in the form below.

Subscribe to Our Newsletter Today!

Sign up today to receive exclusive product updates and offers.

Subscribe to Our Newsletter Today!

Sign up today to receive exclusive product updates and offers.