In the past two weeks, this blog has covered safety topics regarding pump and lift stations. The first blog discussed fall protection and how to include safe and reliable hatches on pumping systems with below-grade structural components. Last week’s blog discussed the use safe disconnects for submersible pump cables. This week, we will look at two configurations for pump station electrical controls that meet code requirements and provide a high level of safety for system operators. These are the Motor Control Center (MCC) and Arc Armor® enclosures, which Romtec Utilities can supply on pump and lift stations for all types of water pumping applications.

An MCC has been the mainstream control configuration for industrial applications for many years, but it is now being used to help municipalities meet NFPA 70E requirements. The reason this style of control configuration is so widely used is because of its superior safety and ease of operation. MCCs are characterized by housing multiple motor controls in separate enclosures. For a pump or lift station, an MCC can comprise the controller, variable frequency drives, meters, odor controls, and other electric control devices. Each control device is housed in a separate enclosure which provides operators with a number of benefits in terms of meeting NFPA 70 (National Electric Code) standards for safety and ease of operation.

The National Fire Protection Association specifies a number of safety requirements when operating or servicing an electrical control panel. These requirements we touched on last week include using a certified electrician for your jurisdiction, undergoing testing, and the use of personal protective equipment (PPE). When these steps are followed, most all controllers can be operated safely. With an MCC, these requirements change because there are separate enclosures with lower hazards and simpler safety protocol. Many of the NFPA 70E requirements can be avoided with an MCC. Using multiple enclosures can increase the cost of the electrical control, but there are other options to provide these benefits while satisfying NFPA 70E workplace safety procedures.

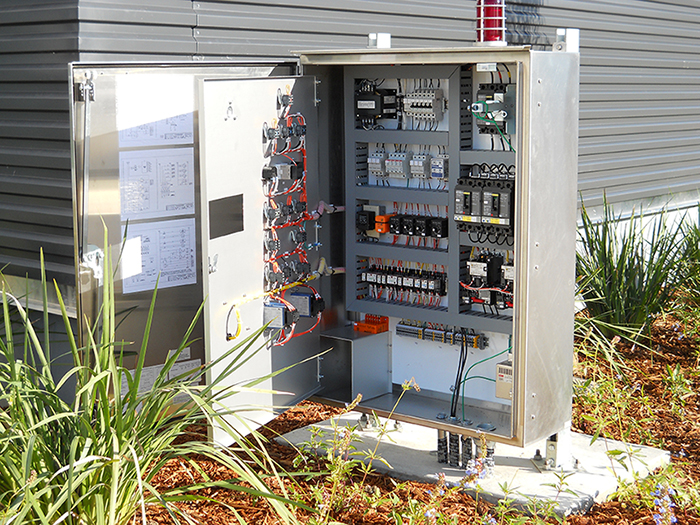

One of the best examples is the Arc Armor® control enclosure. This brings many of the benefits of an MCC into a single, free-standing enclosure. Arc Armor® divides up the electrical controls into different zones to reduce the risk of arcing or electrical shock. The design and function of this enclosure is sophisticated. The high-voltage power connection is in zone 1, the highest risk zone. This zone serves as a shut off for the power to each zone after, and can only be accessed while energized and by following NFPA 70E requirements.

Zone 2 houses the high-voltage terminals for the separate motor controls. It is typically only accessed when zone 1 is de-energized, but it can be accessed while energized by following the NFPA 70E standard procedures. Zone 3 houses the low-voltage controls, and is safe for operators to access while the panel is energized. The low voltage circuits in zone 3 can be accessed with fewer procedures and PPE requirements specified by NFPA 70E. This zone can also be de-energized by de-energizing zone 1. A fourth zone provides an isolation chamber to isolate gasses typically found in wastewater pumping applications.

By using an MCC or Arc Armor® enclosure, the risks associated with operating and servicing pump and lift station electrical controls is drastically reduced. These configurations restrict the access to high-voltage connections and reduce the potential for arc flash. These configurations also create low-voltage zones that can be operated and maintained with fewer hazards and safety regulations. Romtec Utilities supplies pumping systems for wastewater, stormwater, clean water, and industrial applications with safe, reliable, and robust electrical controls.