Romtec Utilities specializes in designing, engineering, and manufacturing package pump stations for all water pumping applications. Our expertise in these systems and our experience in the field has prompted Romtec Utilities to develop many components to improve the functionality of our products, including how they are operated and installed. One of these improvements is the cable tray on the top slab of the wet well. These unique additions to the structural wet well grant a protected space to route disconnect cables through between the in-well components and the control or disconnect panels.

Cable trays from Romtec Utilities were initially developed to benefit maintenance and operations personnel who regularly maintain pump stations. Whether it’s for a routine inspection or emergency repairs, personnel will often need to access components inside the sump. In a typical pump station configuration without a cable tray, pump cables and other wiring are routed through conduits that are installed through the sump walls and are often difficult to access. Pumps that need to be pulled from the wet well for maintenance need to be disconnected from the control panel. This often requires severing the cables with the help of a licensed electrician. Even with a junction box or disconnect panel a licensed electrician may still be needed depending on local regulations. A cable tray, however, eliminates these requirements.

Cable trays are beneficial to any pump station where they are installed. Systems with electrical controls and a disconnect panel using Meltric receptacles typically see the most value. The trough of a cable tray directly connects the interior of the sump to the disconnect panel where Meltric plugs can be installed. This allows any on-site personnel, regardless of certifications, to safely disconnect pumps by unplugging them with the Metric connection. The cable tray can then be unlocked to lift the cables without having to sever them. Eliminating the need to hire electricians whenever pumps need to be pulled from a system can save public utility districts and industrial clients large sums of money over the operating lifespan of a pump station.

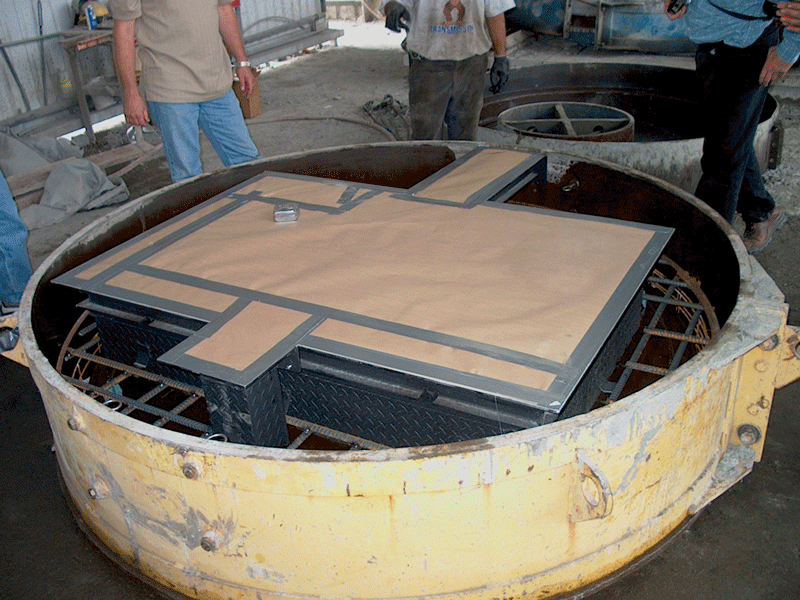

Romtec Utilities’ team of engineers developed the cable tray to work on any size wet well structure. Cable trays are manufactured with aluminum and will meet any traffic ratings necessary including, pedestrian, traffic, and aircraft ratings. The precise requirements of each project and frequent revisions during design phases led us to develop close relationships with our vendors, especially for structural wet well components like top slabs. These relationships allow Romtec Utilities to direct the casting of cable trays into top slabs of any system while they are being manufactured. The final product is a nearly seamless top slab with a secure and protected space to route all of the necessary cables to the electrical panels.

Romtec Utilities is constantly striving to improve the quality and functionality of our product offering. Cable trays were developed and patented by Romtec Utilities as a means to reduce the operating costs of our pump stations and to allow on-site personnel to easily perform maintenance activities without hiring electricians. Cable trays are convenient additions to access hatch/top slab of any pump station and have no impact on a pump stations performance. Contact one of Romtec Utilities Sales Engineers for information about retrofitting an existing pump station with a cable tray or get started on your new pumping system!