Romtec Utilities fabricates several custom components to correctly mount level sensing devices in pump and lift stations. Level sensors are important devices for the long-term functionality of pumping systems for wastewater, stormwater, clean water, and industrial process water applications. Level sensors trigger the pump of the system to start and stop, and a level sensing failure can lead to a system failure. Romtec Utilities always includes redundant level sensing, but in addition to redundancy, Romtec Utilities has developed a number of mounting options for different level sensing technologies to ensure the continual functionality of these devices. Here are some of the options that we manufacture.

The first option can be used with ultrasonic transducers or pressure transducers. These devices need to be hung by a cable that is not also the electrical cable for the device. Ultrasonic transducers are hung at the top of the wet well, above the high-water lever. Pressure transducers are hung near the bottom of the wet well near the low water level. The Romtec Utilities mounting component utilizes the way these devices are designed, that is with threading to be screwed into place. A typical installation would “hard mount” these devices by screwing them into the top or bottom of the wet well, respectively. This type of installation poses no issues for the functionality of these level-sensing devices, but it has definite drawbacks.

The major drawbacks of screwing these devices into place is that it poses a safety hazard during maintenance operations. Pump and lift stations cannot pump completely empty, so for pressure transducers mounted at the bottom of a well, a pumping service needs to be hired to pump out the remaining water so the device can be unscrewed. The other problem is that a person physically needs to enter the well to unscrew devices installed in this manner. Entering in a wet well creates confined space requirements that must be followed for safety. Romtec Utilities designs pump and lift stations to avoid these safety hazards while being fully functional.

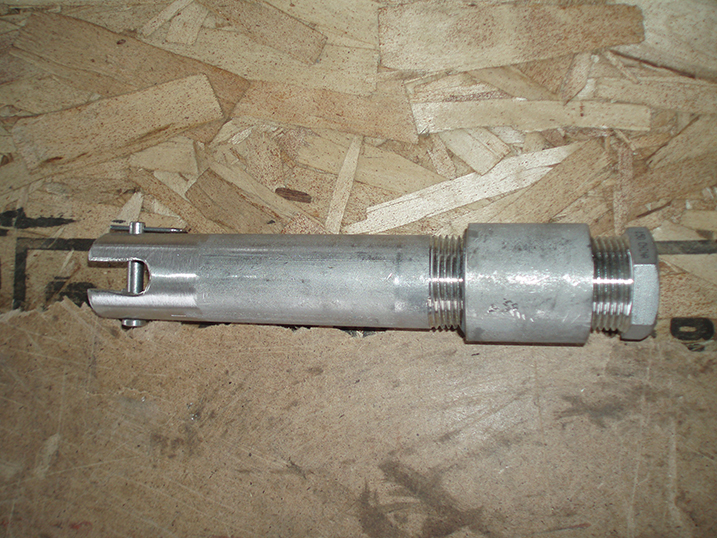

The solution for these devices is a simple hanging bracket that the devices can screw into and then be hung by a separate cable. This allows both ultrasonic transducers and pressure transducers to be pulled out of the well for maintenance, eliminating confined space concerns and the need for a pumping service. This also prevents any potential damages or safety concerns created by hanging these devices by the electric cables. In the case of pressure transducers, a tension cable can also be used if turbulence in the well is a concern.

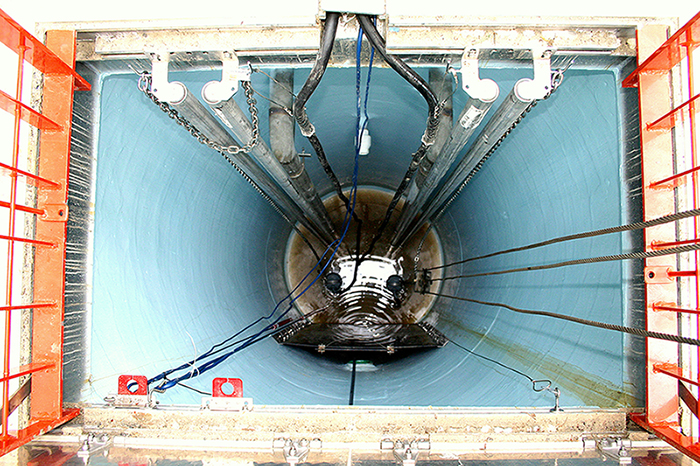

Typically, these brackets are hung via a nut rail that is fabricated into the wet well hatch. There are circumstances that require more flexibility for locating where these devices hang in the well. In these situations, Romtec Utilities developed a mounting arm type of nut rail that extends out from the wall of the wet well to the best location for hanging the level sensing devices. Ultrasonic devices are most often designed to operate without any obstructions that might cause a false level reading, so locating these level sensors to an exact location in the wet well can be an engineering necessity. Similar necessities can require other types of level sensing devices such as floats, probes, and pressure transducers to avoid turbulence and other in-well obstructions. These mounting arms with nut rails help provide a reliable operating area for the device while still allowing the devices to be easily and safely removed for maintenance.