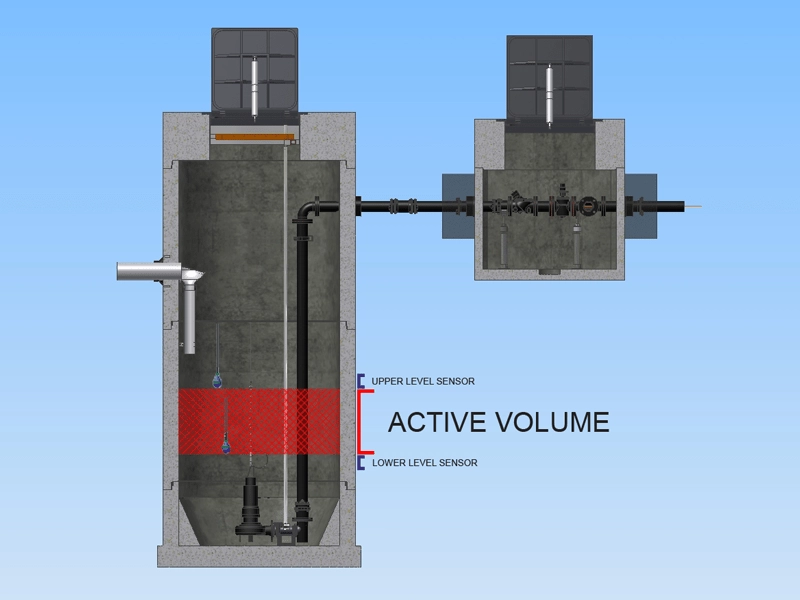

Romtec Utilities designs and supplies pump and lift stations for all types of applications. One key aspect of the pump station engineering is determining the appropriate “active volume” for the pumping system. The active volume describes the volume of water in the well where the pumps are actively pumping. This volume is located between two elevations monitored by level sensors. The top level sensor tells the control panel to cycle a pump on while the lower level sensor tells the control panel to cycle the pump off. This active volume is an important measurement to establish correctly during the pump station design.

The philosophy of this calculation is to ensure that the pump motor will not overheat due to repeated start and stop cycles. When the active volume is too small, the pump cycles occur too frequently, causing potentially dangerous or destructive heat build-up. In systems where multiple pumps are available, the pumps alternate operation cycles, extending the time between individual pump starts. For the purposes of determining an appropriate active volume, we focus on a single pump operating to account for the worst case scenario.

The formula used to determine the active volume is V = T x Q / 4

Where V is the active volume, T is the cycle time, and Q is the pumping rate. The pumping rate is typically determined by Romtec Utilities when finding a pump that will meet the total dynamic head and that will meet or exceed the peak inflow for the system. The cycle time is also determined by Romtec Utilities. Pump manufacturers specify the maximum starts per hour for their pumps. Romtec Utilities uses this number to conservatively find an appropriate cycle time for the pumps. In this calculation, it is better to lean on the conservative side because the only change required for the system is changing the elevations of the level sensors.

Being too conservative is not always appropriate either. When pumping wastewater, for example, if the active volume is too large, the sewage will sit for long periods of time between cycles. This can lead to the water becoming septic, which causes odors and corrosive conditions to form. In more applications like stormwater, long periods between cycles can allow solids to settle out of the water and collect at the bottom of the well. This can create a clogging concern. These scenarios can lead to pump maintenance issues or even premature pump failure.

The best approach when determining the active volume for a pump station is to trend slightly toward the conservative side while not going overboard. This creates an optimal scenario for the pumps to not build up heat that can wear out the pump motors while still pumping the water at frequent, regular intervals. The active volume can be easily changed even after the pump or lift station is installed by adjusting the level sensors as needed. This can account for changes or seasonal differences with inflow to the station.

Comments 8

I am looking for a lift station to handle a 120 lot development (single family). It is about 450 feet with an up hill elevation of 15 feet

Author

Thank you for contacting Romtec Utilities!

Our Sales Team will be in contact with you soon.

looking for a storm drain pump system

vertical lift is 30 feet

horizontal push after lift is 50 feet

need to move approx 100,000 of water a day during the monsoon season.

its for a large storm basin collection area to be pushed up to a road and accross the road to another basin to be used for golf course irrigation.

its an alternate solution to replaceing a culvert 30 feet under the road that has colapsed.

Author

John,

Thank you for reaching out to Romtec Utilities! A representative will be in contact with you soon.

Sincerely,

Romtec Utilities

I need to design the sewage sump pits and pump calculation for a car parking building. This building is of 5 levels below grade level.

Author

Thank you for contacting Romtec Utilities! A representative will reach out to you about your project.

Curiosity Engineering… Is this sound engineering and what is your estimation of what the Pumping Rate and Wet Well volume should be?

Thank you…

Existing Condition:

77,000 gallons per day – Pump Station incoming flow

250 GPM pumps with 72′ TDH (Cornell Pumps)

500 gallon wet well volume (stated to be undersized)

6″ DI Force Main approximately 1000′ length

Notes: Flow monitoring is not available at this pump station, but based on a typical peaking factor of 3.8 at the average daily flow, a peak hourly flow of 227 gpm is estimated, which is approximately 90% of the 250-gpm pump capacity.

Proposed Condition:

131,000 gallons per day, (soon to see) and 151,200 future additional Flows (20 yr buildout)

350 GPM pumps with ? Total Head (currently proposed)

a peaking factor of 3.8 is recommended, for a design-year peak hourly flow (PHF) of 350 gpm.

A minimum flow velocity of 2 feet per second is recommended to prevent solids deposition in the force-main. Since the Pump Station uses a 6-inch diameter force-main, a minimum flow rate of 180 gpm is recommended. The proposed 350-gpm design flow is enough to provide a velocity of approximately 4 feet per second.

700 gallon Wet Well Proposed & normal working storage range should limit pump cycles to no less than 5 minutes (to prevent damage to the pumps or motors)

Same approximate Static Head using current 6″ DI 1000′ long Force Main (no upgrade planned)

Proposed pump station should make use of submersible solids-handling pumps.

Question: Does this Pumping Volume seem adequate and is this Wet Well volume of 700 gallons seem adequate ? Is Pump Cycle Time questionable?

David Ring

802-253-2161

Author

Thank you for your comment. Romtec Utilities will be in touch with you soon.