Romtec Utilities typically tries to reduce the amount of components located in the wet well on new lift station designs. Keeping the wet well clear from too many components will decrease maintenance concerns and improve the functionality of the system, but there are some components that will improve the wet well functions when included. In a lift station design for wastewater, it is important to understand what components to include in the wet well or not.

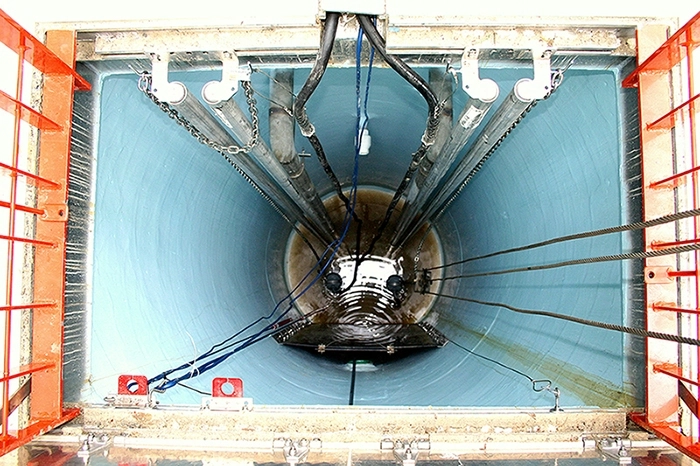

Before discussing the impact of components in the wet well, it is first necessary to understand how a wet well should function. Wastewater contains various solids that will either settle in a wet well or float. To reduce the need for maintenance, a good wet well design should prevent these solids from accumulating in the well. A good wet well will cause wastewater to circle the well as it pumps and funnel toward the suction inlet. The circulation is beneficial because it prevents solids from collecting and draws them to the pumps.

When deciding which components should go into the wet well, it is important to determine if the addition of the components will interfere with the movement of the wastewater. Objects such as ladders, trash baskets, and different types of mounting brackets can interfere with solids in the wastewater, creating areas with the potential for buildup. When this occurs, it makes maintenance in the wet well necessary more frequently and can prevent those and other components from functioning properly.

There are many examples of these types of situations. If a trash basket is used, it might successfully screen out solids for a period of time, but if these solids buildup too much, they can begin to overflow into the well and cause the pumps to clog. A ladder can similarly collect solids like grease or baby wipes. This buildup prevents the ladder from being used until it is rid of the solids. If a mass of solids breaks free from the ladder, the pumps can become clogged.

On the other side of the coin, components such as drop bowls, deflector panels, and properly designed brackets pose no maintenance concerns and actually improve the function of the wet well. These components are designed to not interfere with the movement of the wastewater. They do not provide solids with a place to build-up in any significant amount, and actually decrease the maintenance concerns for the system.

These components differ because they are designed with the intent of improving the functionality of the wet well. Drop bowls and deflector panels serve a similar purpose and are chosen based on the inflow to the wet well. These two devices prevent wastewater from cascading into the well. Cascading wastewater can damage the pumps and discharge piping and can also impact solids onto the wet well and other components. The deflector panel and drop bowl direct inflow to the bottom of the well where it can be pumped immediately, preventing solids from accumulating elsewhere.

This general approach to wet well design will prevent the need for frequent system maintenance and lengthen the lifespan of the in-well components. There are many other dos and don’ts for good wet well design, and Romtec Utilities can help get your lift station an expert design that will function correctly from installation throughout its life cycle. For more information about good wet well design, check out our Tech Info section about Precast & Fiberglass Wet Wells & Mechanical.