Control Panel Repair/Retrofit

Typical Control Panel Retrofit Requirements

- Upgrade from a proprietary controller to a site-specific PLC.

- Upgrade from an existing pump type and horsepower to a new pump type and horsepower.

- Upgrade from an existing level control to a new level control device.

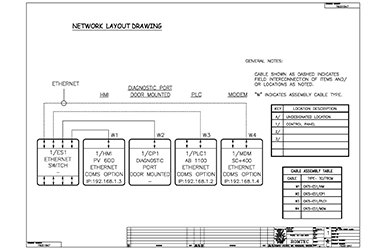

- Add (or change) an existing communication system to a new system or a specific SCADA system.

- Evaluation of an existing system relative to various state and local codes.

- Develop or update software code to provide expanded operation and communication functionality.

- Develop plans to move an existing controller from below grade to above grade or vice versa.

- Integrate other systems to existing or new controls. For example, auxiliary power, flow meters, data & readout, dosing pumps, etc.

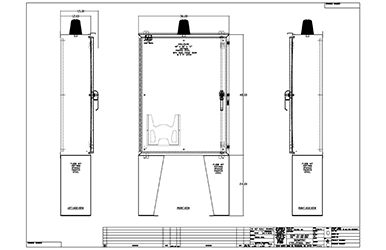

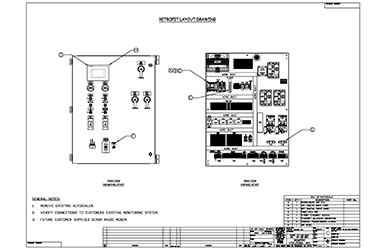

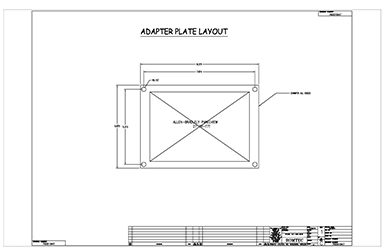

Retrofit AutoCAD Plans

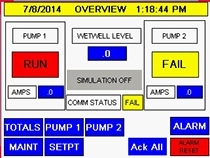

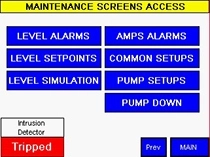

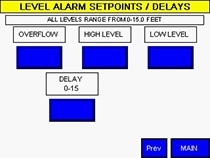

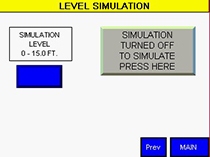

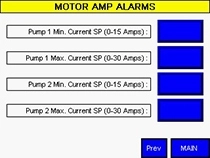

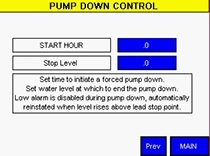

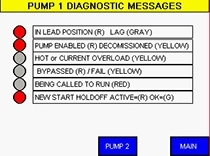

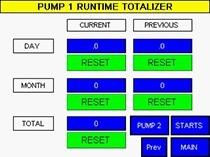

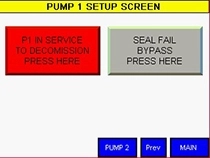

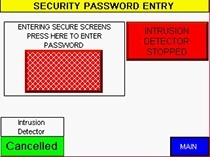

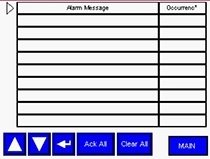

HMI Screen Examples

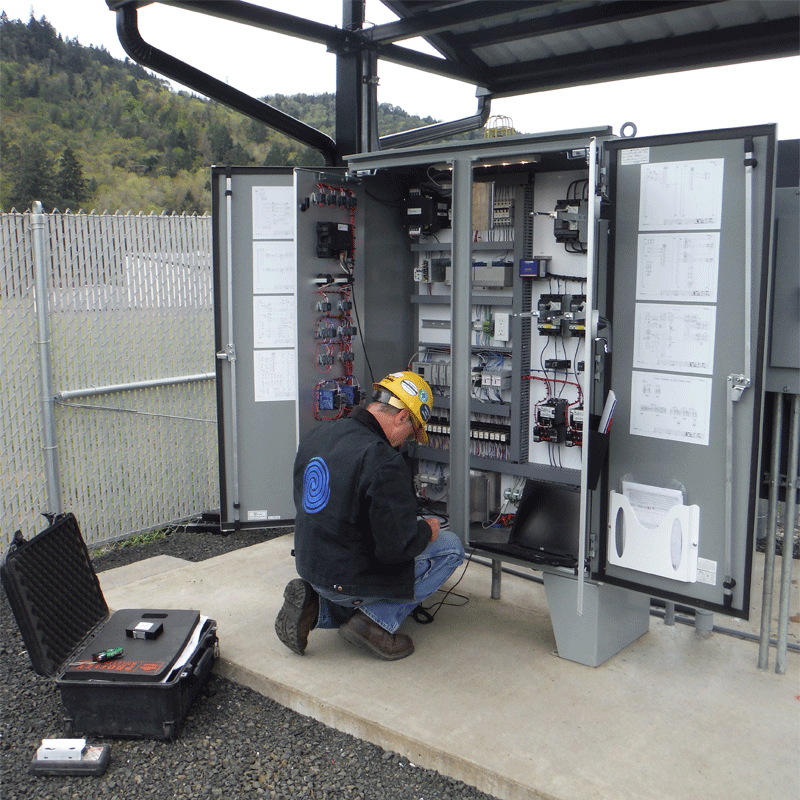

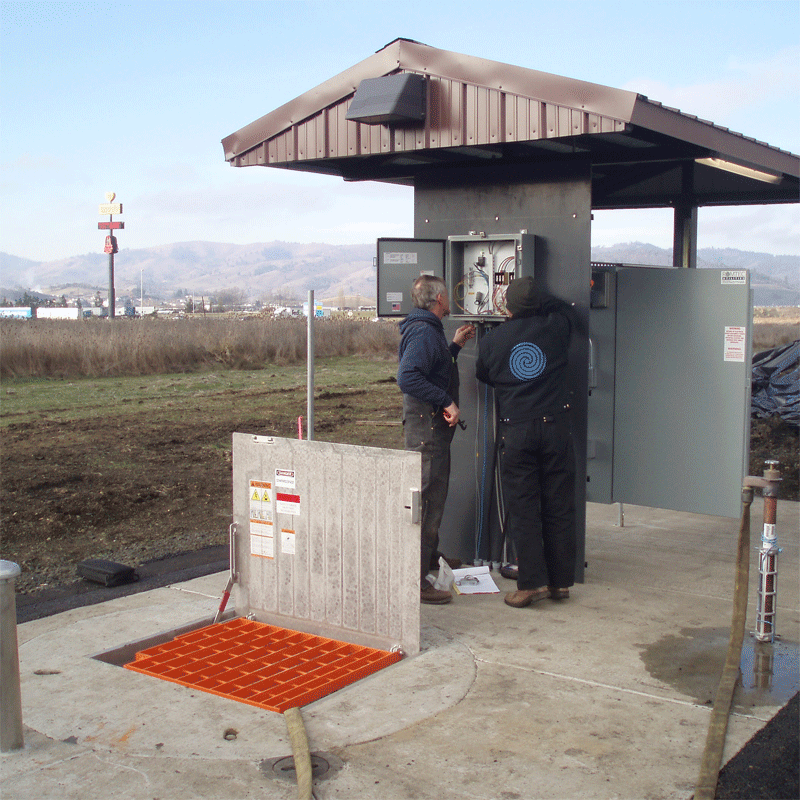

Control Panel Retrofit Process (Order of Business)

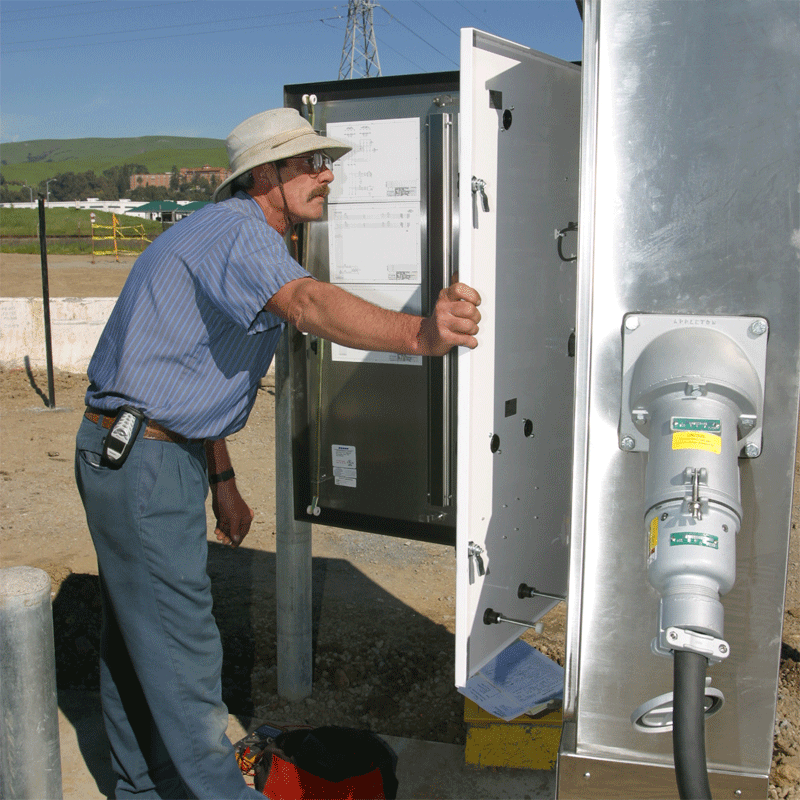

- On-site evaluation of existing control panels and system layout.

- Evaluation of any and all existing documentation.

- Evaluation of an existing problems or issues related to the existing system.

- Clear determination of the anticipated new retrofit configuration and subsequent control and operational parameters.

- Develop scope of work for the control panel and control system retrofit.

- Develop engineered control panel and system drawings.

- Manufacture, delivery, install, and start-up of the new retrofit configuration.

- Provide O&M documentation, training, and warranty.

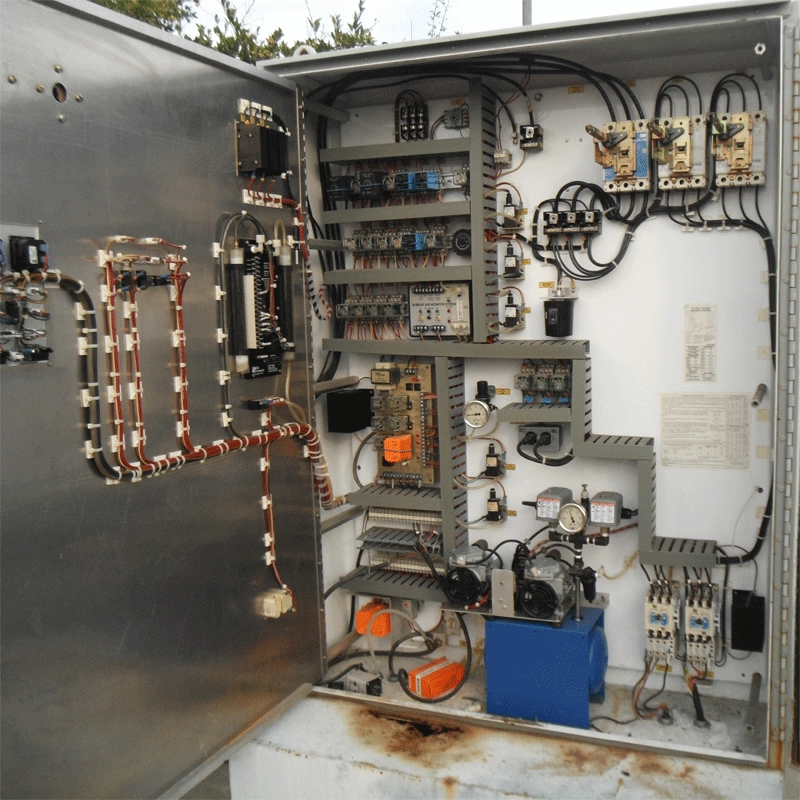

Typical Control Panel Repair Requirements

- Repair of enclosure or structural damage.

- Repair or replacement of:

- Pump starters

- Relays

- PLCs

- HMIs (Touchscreen)

- VFDs

- Level-Sensing devices

- Any and All control panel components

Control Panel Repair Process (Order of Business)

- On-site evaluation of existing problems

- Determine if the problem can be repaired onsite during the evaluations visit.

- Repair as necessary, or identify the problem and write a proposal for a repair of some greater scope.