Romtec Utilities commissions each of its pump stations with a start-up technician. The role of this technician is to start the pump station for the first time and to test the functionality of the system to make sure it functions per the system design criteria. One of these tests is called the draw down test. The draw down test is conducted to measure the pumping rate in order to verify that the pumps will operate at the specified flow requirements. This test is an important part of commissioning new lift stations and there are things to consider onsite to complete this test.

The first requirement for the draw down test is having water available onsite. This step can be as easy as tapping into a nearby fire hydrant, but in most scenarios, water is scheduled to be delivered by truck for the start-up. Having the water available onsite is needed for two processes. The most obvious process is to test the pumps, but the water is also required to fill the force main if it is newly installed. In order to complete a draw down test, the force main must be filled with water.

Romtec designs pump stations based on a project specific set of design criteria. One criterion of design is the desired pumping rate and another is the TDH or Total Dynamic Head conditions. The draw down test is used to measure the pumping rate, and in order for this measurement to be accurate, the force main must be filled. With an empty force main, the head conditions will be very unpredictable when the pumps operate. This will lead to an unreliable reading from the draw down test, and it will be difficult to measure if the desired pumping rate for the pump station is reached. With a filled force main, the head pressure will be consistent for the test.

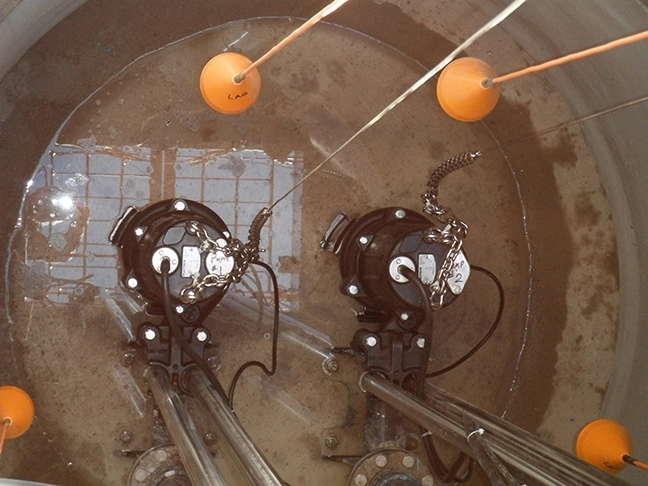

When everything is set up correctly, the draw down test is straightforward. The Romtec Utilities start-up technician runs the pumps and measures how much water is pumped over a given time interval. The pumps run for a specific amount of time and then a measurement is taken for how far down the water was lowered in the well. The technician then makes a simple calculation to determine the volume that was pumped over the time interval. This provides a measurement of the pumping rate. Some control panels can measure the pumping rate, and the start-up technician will verify those readings with the physical measurement.

Commissioning a new pump or lift station is one service Romtec Utilities offers on every project. The start-up technician will conduct several tests to verify that the pumping system performs as designed. The draw down test verifies that the pumping rate is correct, and making sure that the site is prepared with water and a filled force main will give your project a quick start-up process with accurate test results.