Romtec Utilities engineers complete pumping systems, and the structural components are one of the major assemblies for our systems. On virtually every project, the structural assembly carries a load rating specific to the weight tolerance of the system’s structural components. These ratings apply to the well structures, vault structures, and any access hatches. Hatches, in turn, must be designed in such a way to remain functional and easy to use as well as to meet the specified load rating for the entire structural assembly. To reiterate, hatches must first operate at a specified load rating, but they also should work in an easy to use manner. Here are a few examples of hatch designs and how they relate to functionality and meeting structural load requirements.

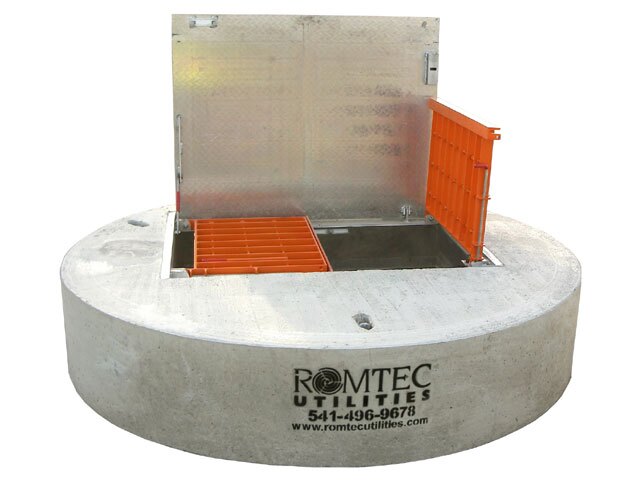

The first type of hatch is typically referred to as a pedestrian rated hatch. These hatches are designed to withstand 300 lb loads per square foot. Typically, these hatches are constructed from aluminum and can be opened and secured by regular personal without assistance. Romtec Utilities always uses hatches with safety grates for fall protection. On pedestrian rated hatches, the safety grate can be opened and locked with simple hinge components. This allows the safety grate to be installed perpendicular or opposite to the hatch door, creating more workable space.

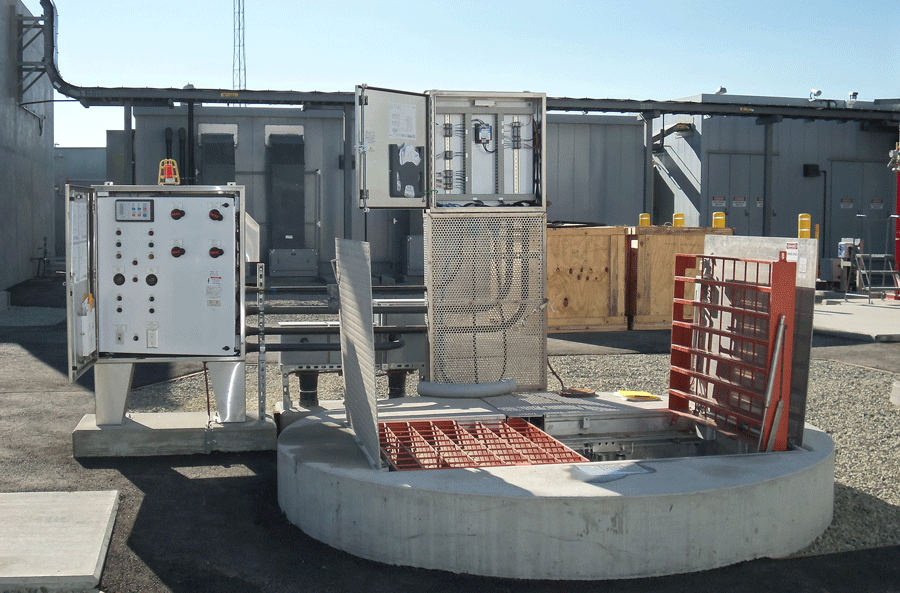

The next type of hatch is often referred to as an H-20 hatch, and it is designed for occasional vehicle weight loads. These hatches are designed to handle loads of over 10 tons to a contact area of a standard vehicle tire from 10 to 20 inch diameter. They are also typically constructed from aluminum. Even being manufactured from lighter weight aluminum, H-20 hatches and their safety grates are much heavier and can represent a closing hazard if not secured. As such, H-20 hatches typically utilize a locking arm. The extra space required for the locking arms means that the safety grate and hatch must open in the same direction. H-20 safety grates can be configured to open perpendicular to the hatch door, but it will often require more materials and a larger overall hatch size.

The final two types of hatches are full-traffic rated and aircraft rated. Full-traffic hatches can withstand loads of up to 20 tons to a contact areas from a 9 inch tire. Aircraft rated hatches can withstand up to 100 tons to a contact area from a 9 inch tire. These hatches are constructed from ductile iron or steel. The heavy weight of the doors for hatches with these ratings typically requires lift assistance from pneumatic gas shocks or springs. Fall protection can be supplied with many types of grates and are usually rated for pedestrian loads. On full-traffic and aircraft rated hatches, the fall protection is typically manufactured with a gap between door and the grate to make space for locking arms and lift assistance devices. On H-20 hatches, the safety grate often times carries the full load and supports the hatch door.

Hatches are important aspects of pumping systems both from a functionality perspective and a safety perspective. Hatches need to withstand the load requirements that will be present at the pumping system site. In order to do this, the design and manufacturing can be different for each type of load rating. Hatch manufacturers offer several designs in order to make the hatches safe and easy to use for maintenance personnel. Romtec Utilities can help get you any hatch you need to meet your site-specific load conditions and functionality preferences.