Romtec Utilities provides the design, supply, and installation of many types of odor control devices. There are many wastewater and sewer pumping applications that require odor control. There are also many unique problems that can be handled by odor control devices and several scenarios where using odor controls will benefit the functionality of a lift station. Let’s look at these common scenarios and how odor controls can help.

The first scenario where odor controls should be included for a wastewater lift station is in applications with long periods between pump cycles. This describes when there is a lengthy period between the cycles of when the pumps are actually pumping. In this scenario, it is very likely that the wastewater will start turning septic. Aside from odor, septic water creates odorous and corrosive gasses, like hydrogen sulfide, that can rapidly deteriorate a lift station and possibly the downstream infrastructure too. Treating septic waster can be very difficult and expensive for treatment plants that are not set up to do so.

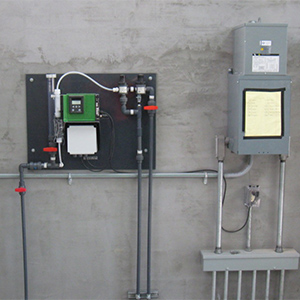

Chemical injection odor controls are a reliable way to prevent wastewater from turning septic. In a situation where wastewater will sit before getting pumped, chemical injection odor controls can eliminate a substantial amount of odor. This type of odor control actually prevents the sewage from turning septic, eliminating other issues associated with pumping septic water. Long pump cycles, however, are not the only scenario where wastewater will turn septic.

In hot climates, wastewater turns septic in a much shorter period of time. It also causes odorous gasses to spread faster. The best method is to pump the system frequently, but it is not always possible to design for frequent pump cycles. In hot climates, design standards will sometimes call for features such as wet well linings, stainless steel piping, and other components designed to resist deterioration from corrosive gasses. In these situations, the goal is not to prevent sewage from turning septic but rather to prevent the smell from escaping the system.

In this scenario, a chemical feed system would be excessive, so the lift station design would be better suited with a passive form of odor control. These types of odor control devices are systems like carbon scrubbers, blowers, ozone, biofilters, and more. These odor control devices take the air and corrosive gasses and essentially filter the odor out of the air before venting it to the atmosphere. Romtec Utilities is experienced at providing all types of passive odor control system as well as chemical feed systems.