Romtec Utilities designs, supplies, and constructs pump and lift stations with all structural, all mechanical, and all electrical and communication systems included. A major aspect of designing systems nationally for all water types in private and public applications is being able to integrate a wide variety of systems and components into a single, engineered pump or lift station. Romtec Utilities has the specific expertise necessary to integrate all types of components into a fully functional pump or lift station package. There are many types of system integration possibilities, and here are a few of the more common scenarios.

Odor control is one of the biggest system needs that commonly gets added to sanitary sewer lift stations. There are many types of odor control systems, and Romtec Utilities has designed lift stations with many different integrated odor control technologies. Odor control systems can be broken down into two categories: passive odor control and chemical feed systems. Passive odor control systems treat odors created by septic wastewater in a variety of different means. Typically, air is vented from the lift station to a media bed that filters out the odors and vents cleaner smelling air. Passive odor control systems can use a wide-variety of media and filters, and Romtec Utilities can integrate these components, as well as the electrical controls into our lift station design and supply package.

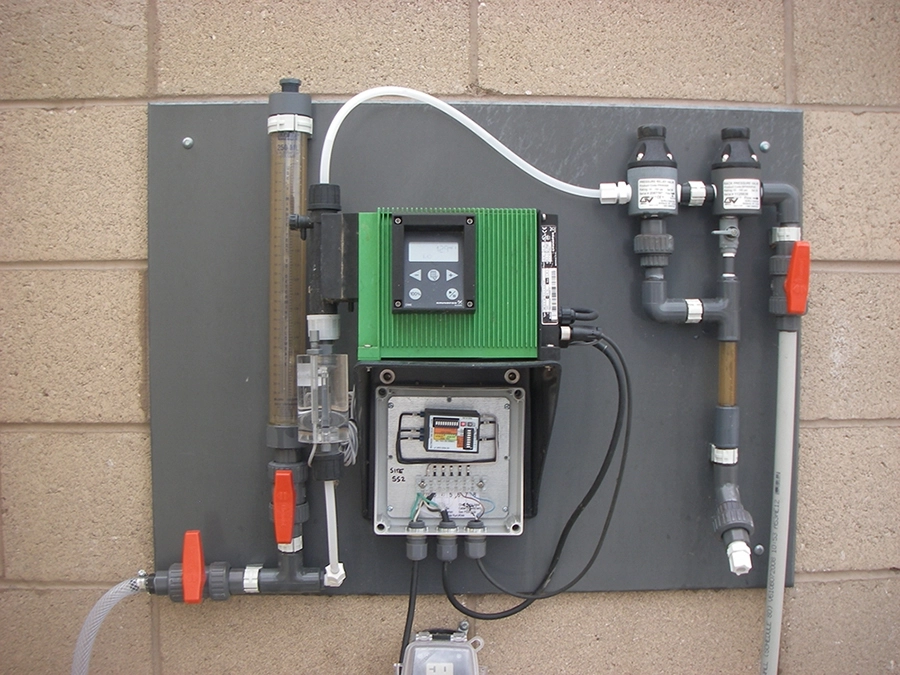

Chemical feed systems for odor control are typically more complex than passive odor controls. These systems inject different chemicals into the sewage to prevent it from turning septic. When sewage is prevented from turning septic, there is no hydrogen sulfide off-gassing, which is what causes unpleasant odors. Chemical feed systems have different integration requirements such as a chemical feed tank and injection controls. Romtec Utilities designs lift stations with all the hardware and control devices necessary to provide reliable chemical feed odor controls. These systems are not an “add-on” but a fully integrated system that functions with the lift station as a single, engineered system.

Another common system integration need for pump and lift stations is for Supervisory Control And Data Acquisition, SCADA. When Romtec Utilities engineers pump and lift station electrical controls, it is important to understand the needs of the customer. In many industrial applications and some commercial and public applications, SCADA is used to monitor a wide-variety of systems from a single terminal or channel. Integrating pump and lift station electrical controls and communications into an existing SCADA system takes expertise with a wide range of control and communication platforms. Romtec Utilities understands the available technologies and devices to be able to help our customers receive completely integrated SCADA systems with their pump or lift station electrical controls.

The final common system that is often required for pump and lift stations is backup power generators. Integrating backup power generators requires a lot of information depending on the power requirements, types of generators, and location of the generator. Diesel generators, for example, need to be sized to the load of the pump or lift station. When diesel generators operate under a light load, it can lead to problems such as “wet stacking” or not consuming the proper fuel amount and leaking it into the exhaust system. Another consideration with diesel generators is adding load banks. This allows the diesel generator to operate under a load during maintenance and testing cycles.

Generators can be portable and permanent. Each type of generator is integrated with different components to function with the pump or lift station. A portable generator needs to have a receptacle available to attach to the electrical controls. Receptacles must be properly sized and provided in a location where a portable generator can be easily connected to the pumping system during a power outage. Permanent generators can be located on a slab foundation or in a control building. These types of generators typically require an automatic transfer switch to transfer power between the power grid and the generator during outages. There are many other considerations for integrating a generator into a control building, and Romtec Utilities has the necessary expertise to provide complete designs to meet the customer’s backup power needs.

There are many more systems that can be integrated into a pump or lift station from flow metering to pigging ports. These three examples are simply some of the most common integration scenarios encountered. To Romtec Utilities, you get a complete pumping system that is designed, engineered, supplied, and installed as a complete integral system. Each of these scenarios are a fully function aspect of the complete system and not simply an addition. If you have questions or comments about integrating unique systems into a pump or lift station, contact Romtec Utilities today to discuss your project.