Pump Stations Designed For Current and Future Flows

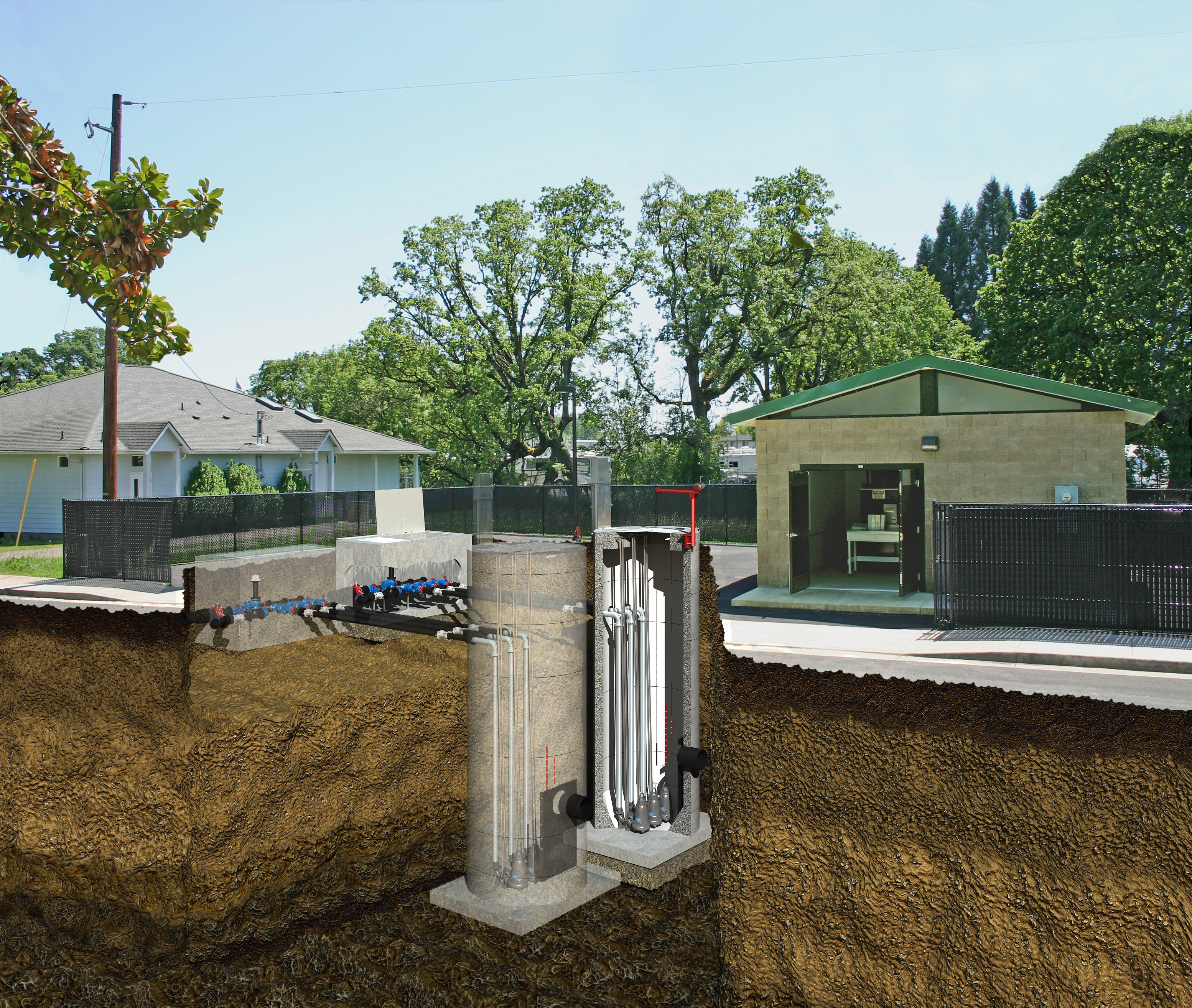

“Phased” (now and future flow) pump stations are common for large developments and ideal for situations in which the inflow to a lift station will increase over time. These types of systems are designed to run optimally at each phase. One might think that a large system designed to handle the maximum inflow found at full-buildout may be the best way to go. However, even though the system is sized for a large inflow, inflow will be a fraction of this amount when it is first commissioned.

Large systems with low flows can create issues such as solids falling out of suspension and odors. Romtec Utilities is familiar with providing lift stations for developments of all sizes, and has the capability and expertise to design systems that will operate efficiently during each phase as the population and subsequent sewer volume grows.

“Phased” systems are systems that will need to meet the needs of increased requirements throughout their operational life. For instance, when a lift station is commissioned, it may be serving around a hundred homes. As the area grows and more homes are built, and potentially commercial structures and schools, the lift station will need to be able to service the homes that were initially there as well as the structures that have been added.

A “phased” lift station may need to be designed for numerous phases of operation. Depending on the size of the development, there may be three or more phases that the lift station needs to accommodate. This can be achieved in two ways: adding pumps to a system to increase the pumping rate, or replacing the pumps to a higher horsepower pump. Both systems have special design considerations to take in order to have an efficient lift station.

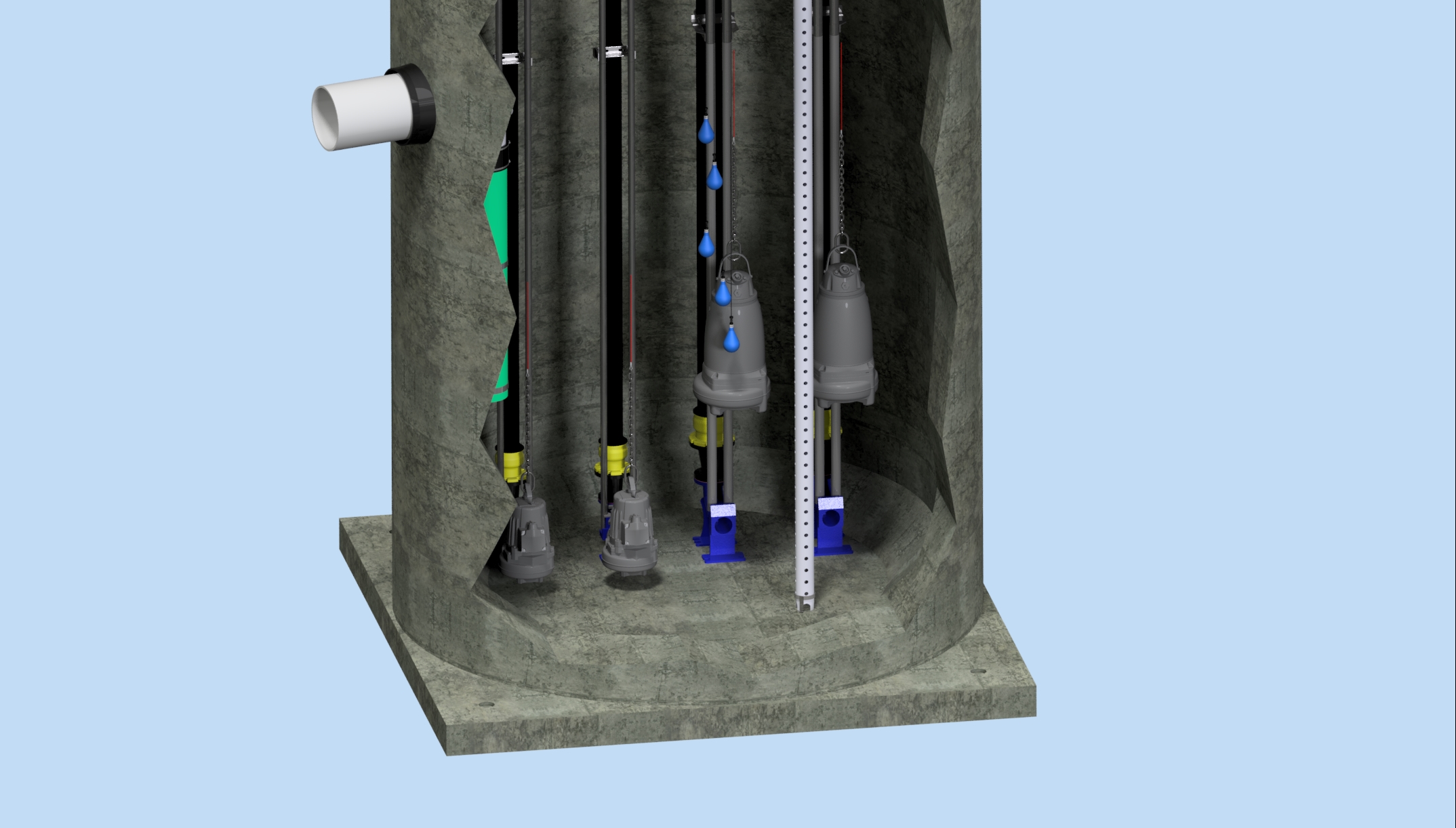

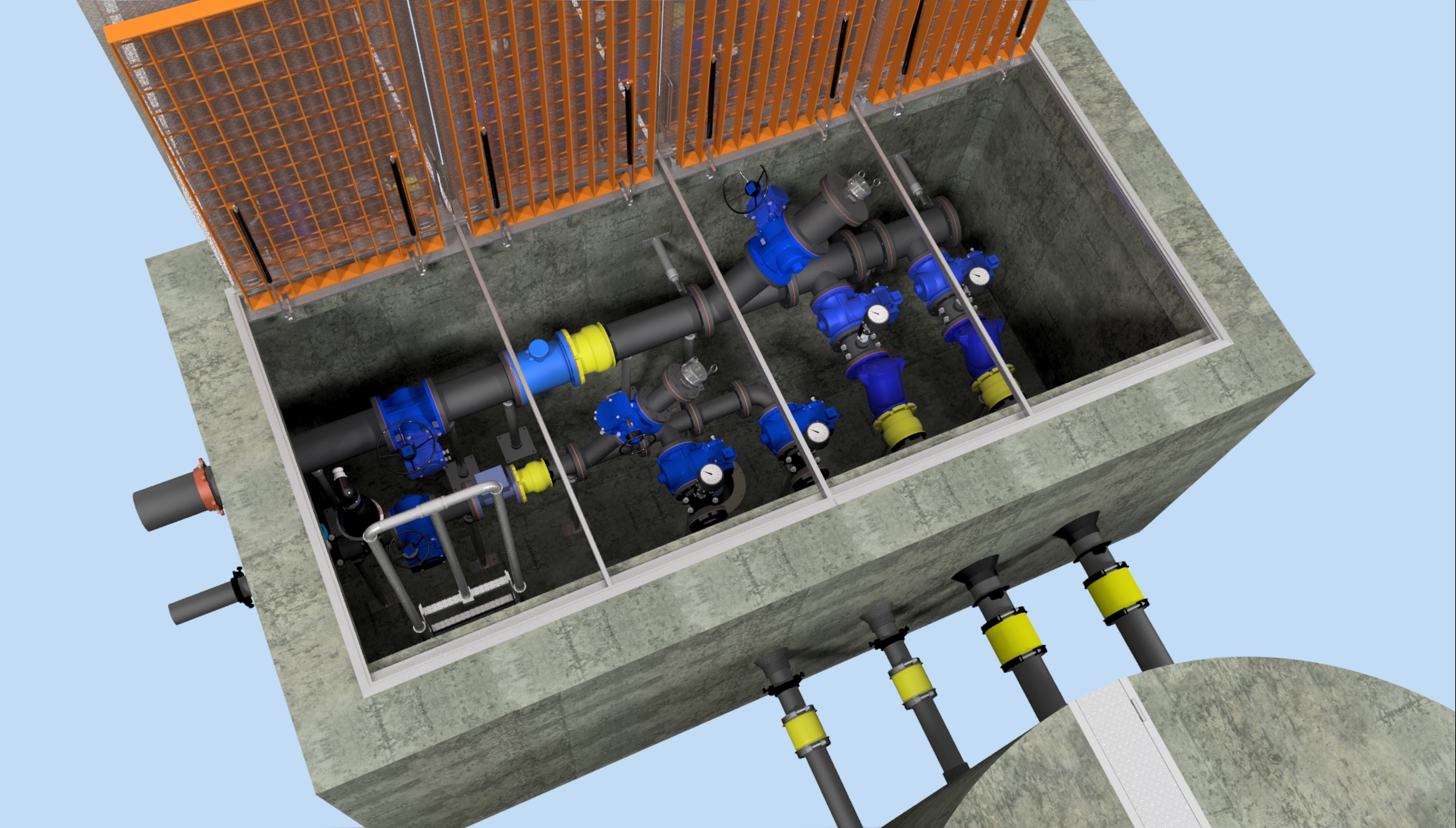

In systems that will require the future installation of additional pumps, one major factor is the size of the wet well, which will need to be able to accommodate the equipment for the initial phase as well as the future phases. For instance, a duplex system may need an additional pump or two to meet the requirements of the second phase. With the transition from one phase to another, the additional pumps will be installed, requiring adequate space in the wet well. Valve vaults and meter vaults will also need to be large enough to accommodate the additional equipment required when the supplemental pumps are installed.

The Valley Knolls project in Douglas County, Nevada, is a good example of this type of “phased” system. The wet well in this project began its operational life with only 2 pumps, but is large enough, and has the piping to accommodate, two additional pumps when flows to the wet well increase. The valve vault in this system is similar to the wet well, with adequate valves for initial requirements, but with additional space and piping required for the additional pumps. The steps taken in the Valley Knolls project, with consideration for the next phase, will make it easy to transition the lift station from one stage to the next without extensive work.

While a wet well needs to be large enough to accommodate future flows and equipment, there is also a fine balance between large enough and too large. In wet wells that are too large, solids can fall out of suspension and float down to the floor of the well, creating thick build up on the wet well surfaces and submerged equipment. Build up from these solids can be a maintenance nightmare and cause damage to the lift station components, emphasizing the importance of a system with the correct well size.

Rather than adding additional equipment, in some systems the equipment will be swapped out to higher horsepower pumps to handle increased flows. In these scenarios, the pumps will be replaced as the pumping requirements increase, but the system will always have the same number of pumps as when it was initially commissioned. This is the case with the Mineral Point Project in Stanwood, Washington.

In systems like the Mineral Point Lift Station, the wet well will not need as much additional space in the bottom of the well. Lift stations designed in this way can have a smaller inner diameter well, but may need to be deeper to accommodate the increased flows in later phases. In order to replace the pumps for future phases, these “phased” systems require discharge elbows that can accommodate higher horsepower pumps. Replacing the pumps is as simple as lifting out the ‘old’ and setting the ‘new’.

“Phased” pump stations, regardless of the type, are complex in their design requirements. Not only do they need to be able to meet the pumping requirements of varying stages, but they also need to be easy to maintain and transition from phase to phase. Romtec Utilities experts have the experience and knowledge to design successful “phased” systems, allowing our customers to focus on expanding their developments.