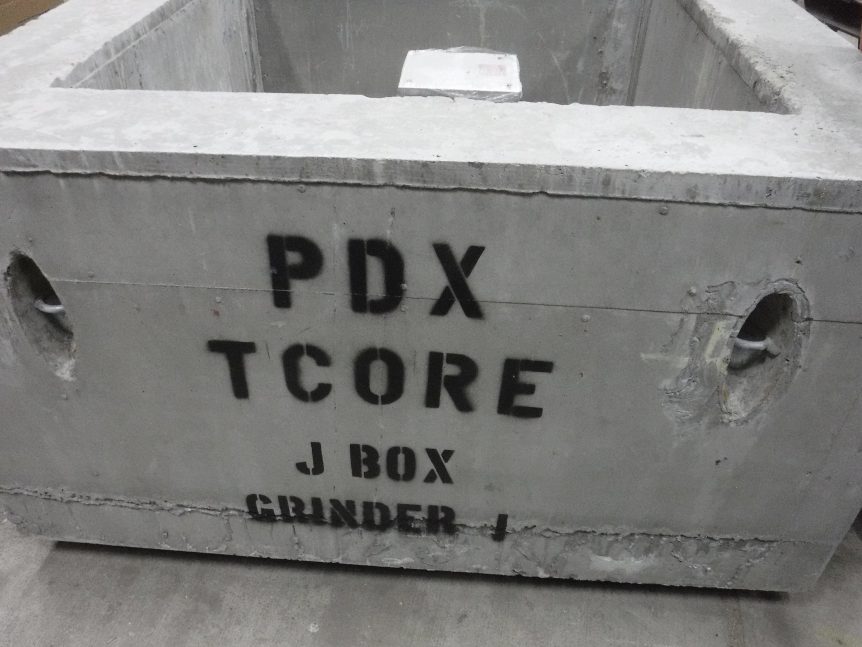

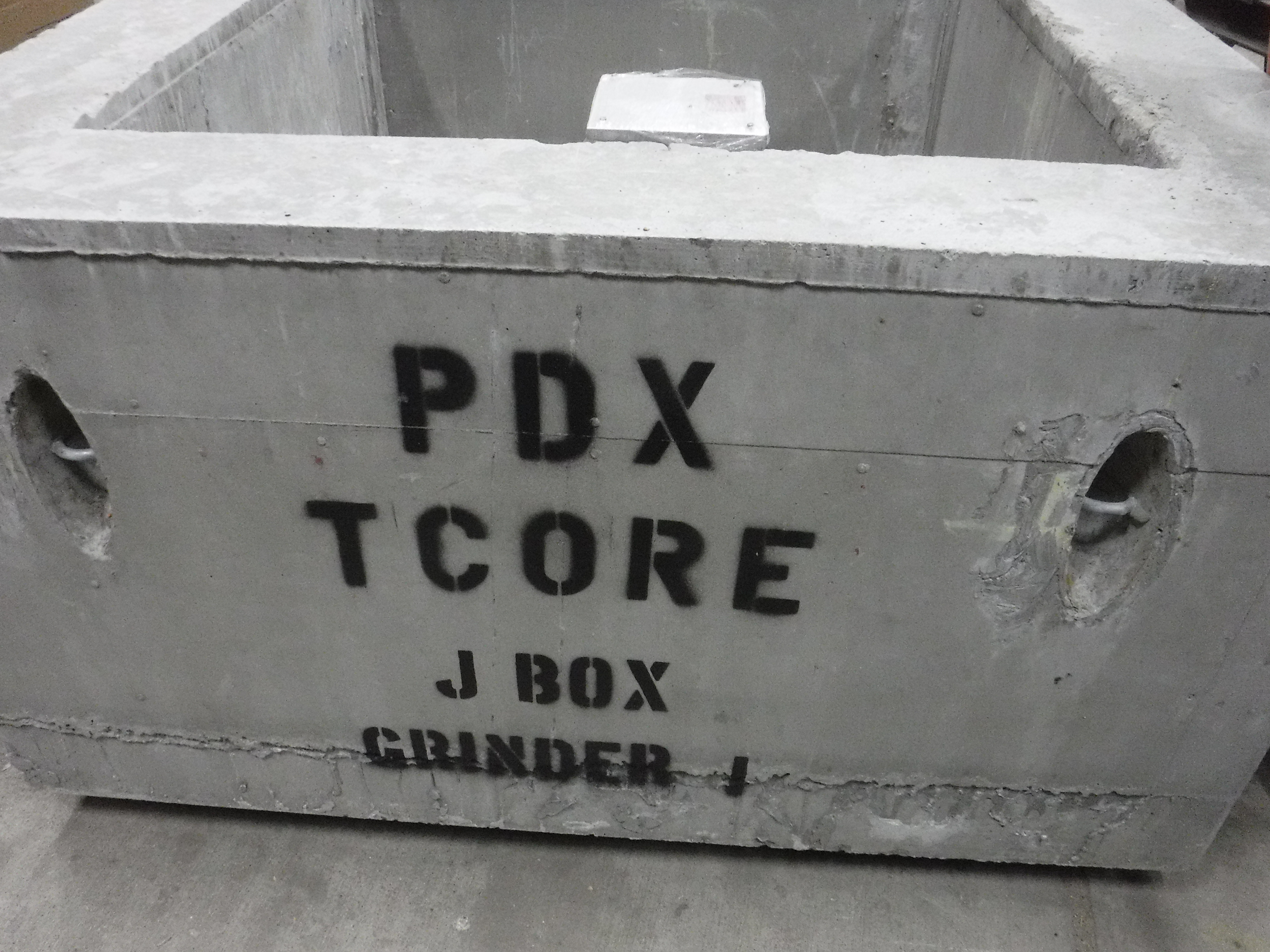

“Romtec Utilities’ Custom Junction Box”

The Portland Airport Terminal Core Redevelopment project, also known as the PDX TCore project, is a unique design that consists of a wastewater lift station, two muffin monsters (in line grinders), and three in-ground junction boxes. To execute this project, the Port of Portland hired Coffman Excavation as the General Contractor. Coffman Excavation identified the unique challenges this project presented, and understood the value Romtec Utilities would bring based on the successful completion of another project for the Port of Portland; the Port of Portland PACR project which was comprised of three individual sewer and wastewater lift stations.

A junction box is an above-grade or in-ground structure that provides safe electrical connections between electrical components, such as pumps and level sensors, and the control panel. One main reason for including a junction box on site is to avoid excessively long wire/cable runs. The cables connected to the pumps can be expensive, and with long runs, it is easy for the cost of cables to increase. Additionally, cables may be limited by the maximum cable lengths supplied by the pump manufacturer. The junction boxes specific to the PDX TCore project also serve as the boundary for the Class 1 Division 1 area that is inherent to a wastewater application. Romtec Utilities’ design meets or exceeds National Electrical Code (NEC) and National Fire Protection Association (NFPA) requirements.

Romtec Utilities’ junction boxes feature a robust precast design that arrives to the construction site with pre-cored holes for quick and easy “Plug and Play” installation. They are specifically designed to streamline construction and ease of maintenance. From spacing considerations, to 100% component supply, Romtec Utilities’ Engineers ensure no details are overlooked. Each junction box provides adequate room for workers to easily pull and terminate conductors in the event of maintenance or replacement. For each pump, there are explosion proof cable glands and conduit outlet boxes for wire connections, and for level sensing, there are intrinsically safe terminals placed inside a NEMA 4X enclosure. All of the seal-off fittings and cable glands come standard.

When junction boxes are installed sub-grade, or below the ground level, additional measures must be taken for potential water intrusion. If left uncontrolled, water will damage the electrical equipment and prevent the station from operating as designed. In Romtec Utilities’ junction boxes, all connections are elevated above the vault floor to prevent the connections from sitting in any water that enters the vault.

In addition to elevating the connections, a drain is also installed in the floor to prevent water from accumulating in the vault. The drain directs the water into the wet well where a check valve is installed to prevent the backflow of water to the vault from the well. A float switch provides an alarm notification in the event the vault does start to accumulate water, allowing maintenance personnel to handle the problem before the connections are damaged.

Romtec Utilities’ junction boxes provide several additional benefits. When troubleshooting is required, our cable entry and termination design promotes easy component identification, thereby eliminating confusion during maintenance or replacement.

Junction boxes are an important and often overlooked detail of lift station design, Romtec Utilities’ vast experience in complex lift station design and installation is bringing a significant value to the PDX TCore project. Romtec Utilities’ junction boxes reduce construction and maintenance costs, mitigate water intrusion, are easy to install, and they’re code compliant. Our approach to the lift station junction box is a perfect example of how Romtec Utilities applies practical solutions to complex problems. With Romtec Utilities’ years of expertise and experience, our customers can count on the success of their systems.