Romtec Utilities designs and supplies pump stations for many different types of applications, including leachate collection and removal systems. Leachate pump stations are required whenever water passes through a bed of solids and extracts contaminating elements. The most common scenario for collecting and pumping leachate is for landfills, but there are industrial applications as well. Leachate can be corrosive, acidic, and toxic toward all lifeforms and for many years was allowed to runoff into watersheds or settle into groundwater. Today, collecting and properly treating or disposing of leachate is a requirement for most facilities that produce it.

The water properties of leachate can make it difficult handle, and unlike wastewater that has a relatively consistent viscosity and pH, leachate can vary drastically in different locations, seasons, and weather conditions. These water conditions require our engineers to configure pumping systems with components designed to handle severe water conditions. Romtec Utilities has the necessary design and engineering experience to understand each specific component and the respective manufacturers. It is important to use components from manufacturers with good track records, documentation, product testing, and support.

One substantial consideration for pumping leachate is the well or collection system. Whereas concrete is typical for trenches and collection channels, concrete as the wet well for a pumping system may require some additional engineering or a more robust material. Other options for the wet well tank include utilizing coatings or liners for precast concrete wells, fiberglass wells, or precast polymer concrete wells. Each method should be considered in terms of cost and the operation of the site. In situations where leachate will sit in the well for long periods, untreated concrete may not be appropriate.

Leachate can be disposed through many different processes depending on the capabilities of the facility. Some industrial sites or large waste management sites may have water treatment or pretreatment onsite. Other locations may utilize retention or evaporation ponds. It can also be typical to pump to a holding tank for loading into tankers. Then, the leachate is shipped to a treatment facility capable of handling that type of water. Whatever methodology is being used, Romtec Utilities can size your system appropriately to meet your pumping requirements and to keep your budget economical.

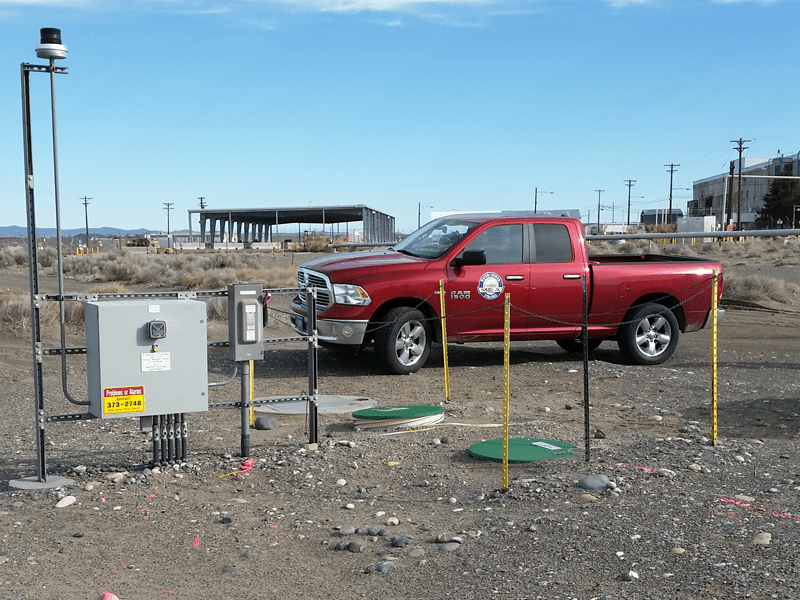

One final aspect of a good leachate pump station is including an electrical control panel that fits the needs of the facility. Some landfills and industrial sites will utilize a SCADA system for controls throughout the facility. Romtec Utilities can integrate your pump station control panel into an existing SCADA system. At other facilities, the controls may be remote or be a part of a detached system. In this scenario, Romtec Utilities can also design simple, low-cost controls. When it comes to providing a pump station for a leachate collection and removal system, Romtec Utilities has the experience and expertise you need!

Comments 5

HI, were looking for a 45 GPM 3 stage (P2K45.3) w/ 1 HP 3/230v motor, 100’ power cable and 100’ transducer, can you please send us a quote?

Thank you!

Author

Krystal,

Thank you for contacting Romtec Utilities! A representative will be in touch with you soon.

Sincerely,

Romtec Utilities

Hello I need to empty a leachate pond of 30000 m3 at a rate of 450 m3 per day. The pond has 11 meters of depth. The leachate has to be pumñed to another pond that is 24 meters above the original pond and 135 meters of distance

Hello I need to empty a leachate pond of 30000 m3 at a rate of 100 m3 per day. The pond has 28 meters of depth. The leachate has to be pumñed to another pond that is 3000 meters of distance

Author

Thank you for your inquiry. A Romtec Utilities Representative will be in touch with you soon.