Romtec Utilities engineers and supplies pump stations for many different applications for industrial facilities across the country. These facilities range from chemical manufacturing to oil & gas refineries, and power generation is another industrial market where Romtec Utilities excels. We have supplied many different types of pumping systems for power gen facilities for wastewater, condensate, and other types of process water. A frequent scenario for a Romtec Utilities pump station is pumping for a heat recovery steam generator (HRSG) or blowdown process in cogeneration/combined-cycle power plants.

Cogeneration and combined-cycle power plants derive power from natural gas in two methods. The first method is igniting natural gas under high pressure. This creates rapid expansion that is used to rotate a power generating turbine. After the ignited gasses pass through the turbine, a significant amount of energy is still available in the form of heat. Using water pipes in the stream of the gas, steam is generated from recovered heat that turns a steam turbine generator. This is where the terms “cogeneration” and “combined cycle” are derived, from the extraction of energy through two processes to generate electricity.

HRSG and blowdown pump stations handle the water used in the secondary stages of this process. Frequently, this water is super-heated and can be corrosive. The super heating of the water distills it, making it more likely to strip minerals from pipes and other equipment it encounters. Designing pump stations for these applications must account for the unique water conditions created during the power generating process. Having direct knowledge about manufacturers and the capabilities of their products is a valuable asset when dealing with corrosive water conditions.

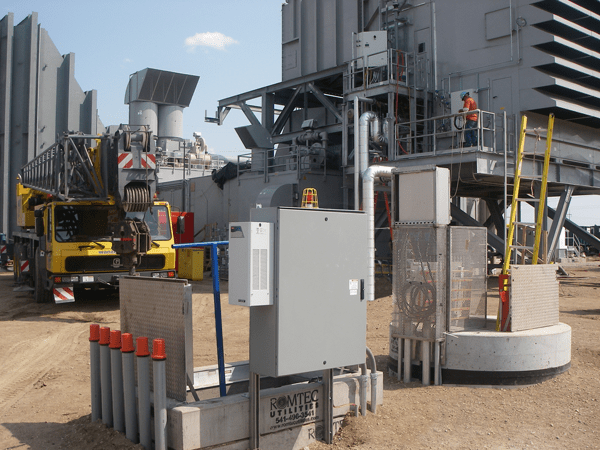

Romtec Utilities has supplied many pump stations that are dedicated for HRSG and blowdown process in power gen facilities. The success of these pump stations relies on understanding the water conditions, understanding the pumping requirements, understanding the equipment, and finally, understanding the electrical control preferences of the facility. This last step can be very important. Electrical controls are particular to each pump station, and they can exist as an isolated system or integrate with a larger control scheme or SCADA system. Romtec Utilities has helped power gen facilities get control panels that fit their exact preferences for pump station controls on HRSG and blowdown systems.

Power gen is a huge industry, and Romtec Utilities has worked with many companies on many projects. Most often, these systems are a part of the sewer system for new plants, but Romtec Utilities also has pump stations that can handle the pumping needs of required during the power gen cycle. If you have more questions about our pumping systems or about HRSG and Blowdown pump stations, contact our sales team today to learn more!