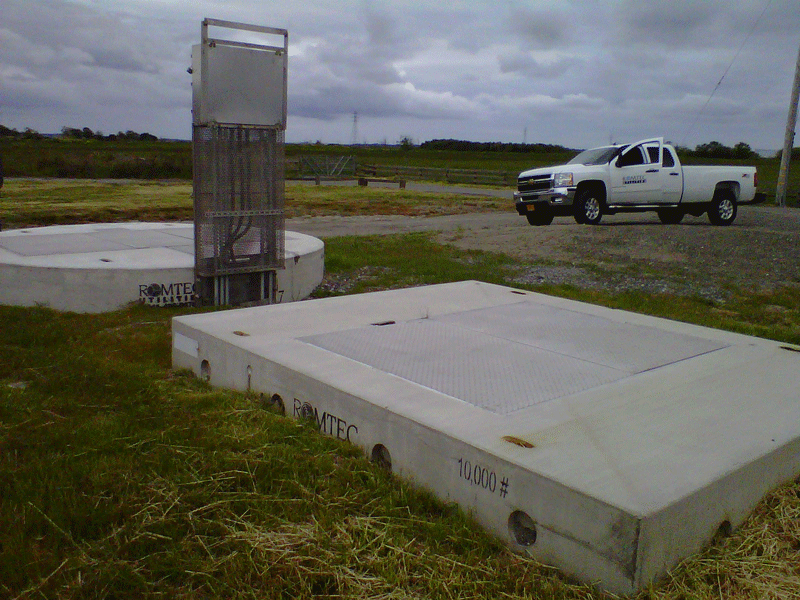

Romtec Utilities designs, manufactures, and supplies pumping systems for many different applications. Our systems include all structural, all mechanical, all electrical, and all communications systems in a single purchase. Many of our systems are designed and supplied to handle sewage and wastewater flows in a lift station design. In many scenarios, these lift stations are for new construction like residential and commercial developments. Sewer infrastructure is typically available, and with some projects, engineers and developers will try to make use of existing infrastructure such as an existing force main. There are many benefits and challenges when pumping into an existing force main.

The benefits of pumping into an existing force main are really related to two big advantages. One: it saves money. Two: it saves time. This much is typically beyond dispute. The reason it is not always an option is because it can be challenging to do. First, there are challenges that are completely unrelated to the design and engineering of the lift station. In other words, Romtec Utilities cannot help with these challenges. These are often the hardest challenges to overcome.

The first question is to find out who owns the existing force main and if they will let you pump into it. Many times, force mains and pressure mains are owned by local utility district, but they can also be owned by private entities, cooperatives, and other organizations. The next question is that of the design of the existing pressure system. Unlike the first challenge, this issue is pretty rigid. The existing pressure sewer may not be able to handle more pressure, or it may not be able to handle the specific added pressure of the new system. This can be related to the control valves, the force main material, or any number of other factors. If the system can’t handle it or the owner won’t allow it, pumping into an existing force main may not be possible.

Assuming that it is possible and permission is granted, then there are more challenges to overcome for pumping into an existing force main. The good news is that these challenges are related to the design of the wastewater lift station and Romtec Utilities can help you overcome a vast number of difficult scenarios. With wastewater & sewer, the design options are typically more restricted due to the probability of suspended solids in the water. With the presence of solids, some design configurations, like utilizing a back-pressure sustaining valve, are not suitable because they will be more likely to clog in this type of application.

The most reliable and affordable solutions for pumping wastewater and sewer into an existing pressure sewer system will utilize Variable Frequency Drives, also called VFDs. A VFD is able to regulate the frequency of the incoming power to a pump. By regulating the power supply to the pump motors, the pumps can be ramped up and down to meet variable conditions in the downstream system. There are two primary methods for controlling the VFDs in this type of system design. You can utilize a pressure transducer or a flow meter installed on the new force main prior to the junction into the existing pressure sewer system.

The functionality of these two options is very similar. With a pressure transducer, the devices measures the pressure in the force main. If the pressure in the existing pressure main is consistent, at let’s say 50 psi, then the pressure transducer must read over 50 psi to overcome the pressure for your pumping system to pump into. If the pressure transducer is reading a lower pressure than the 50 psi for this example, the signal to the control panel will ramp up the VFDs to supply a higher frequency of power to the pump motors. This causes the pumps to spin faster and increases the pressure until the system is pumping over 50 psi and can overcome the existing pressure conditions.

A flow meter, on the other hand, is more suited to situations where the existing pressure sewer system has variable pressure conditions. In this scenario, the flow meter can be set to a desirable discharge flow rate, at let’s say 50 gpm. When the flow meter reads a pumping rate lower than 50 gpm, the control panel ramps up the VFDs and the pumping rate increases until the target flow is achieved. With the same process, the flow can be reduced. For example, a pump station on the existing pressure sewer system might shut off, causing the pressure to drop in the existing pressure main. This would cause the flow rate in the new system to spike. The flow meter will read the increase in flow and the control panel will signal the VFDs to supply a lower power frequency to the pumps. This will cause the pumping rate to fall until the desired rate is reached.

There are many different ways to engineer a new wastewater or sewer lift station to pump into and existing pressure sewer main, but these two configurations are by far and away the most common and most reliable options for most applications. In addition to the design challenges, project managers and engineers must approach the preliminary challenges of gaining permission and as-built specifications for the existing force main. Only after these two challenges are overcome can a true system design be created. For more information about this and other challenging pumping scenarios, contact Romtec Utilities!