Romtec Utilities works with our clients to provide the best pump stations for all types of applications, including all the required components by the customer or their engineers. Recently, our Production Crews underwent training for how to apply a 3-part series of coatings with Tnemec products to provide some of the best concrete protection available. Romtec Utilities supplies many types of coatings, liners, and concrete protection methods, and receiving training in this series will allow for better quality control when applying this series of products. Here is an overview of the coatings and how they work.

First, concrete wet well coatings are valuable for many reasons, but perhaps the biggest reason is to protect against the destructive presence of H2S gas in wastewater applications. Another big advantage is creating a smooth wall surface so that suspended solids can’t get caught and will instead slide down to the pumps as the water level is pumped down. Coatings can increase the lifespan of a well while also improving its functionality and maintenance requirements. These advantages are magnified for districts and organizations that manage more than one pumping system where solids and/or H2S are present.

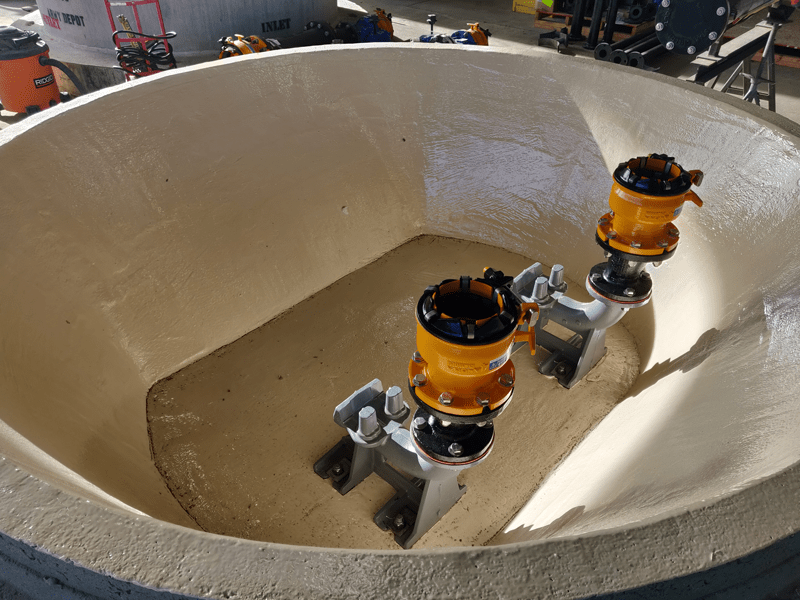

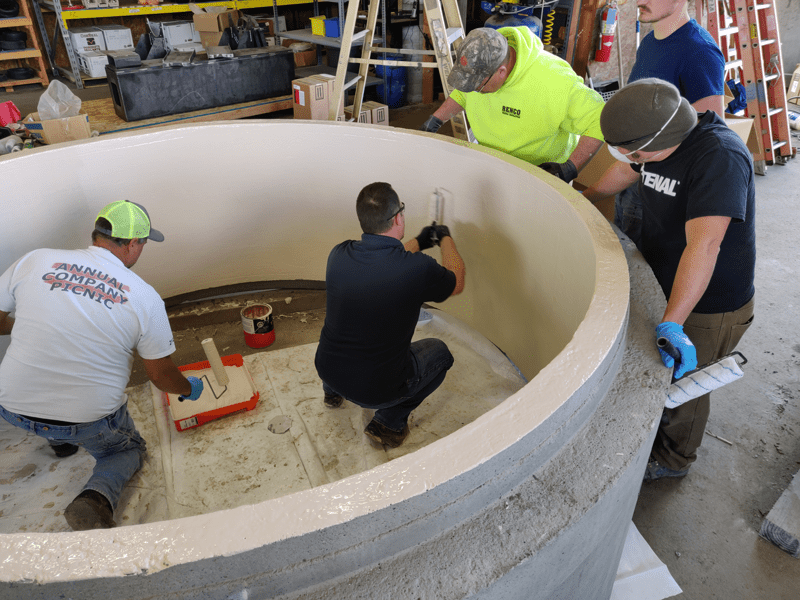

The 3-part Tnemec coating system includes many more steps than three. First the concrete structures must be sandblasted to create a rough surface. This allows the first part of the coating series to create a strong binding with the concrete. The first part of the series is put on with as smooth and even of an application as possible. This allows the next two parts to further smooth out the interior well surfaces. After this, the concrete has to be grooved a notched in specific locations that create pockets for the second part of the series to “grab,” giving the coatings more support for long-term use. Finally, the third part of the coating series is applied.

These coatings and the additional application steps help create a contiguous layer on the inside of the well that protects the concrete and also withstands ambient forces like changing temperatures and gravity. Well coatings are good additions to pumping systems, but they can sometimes be challenging due to their cure times and the cure times of the concrete wells. This can lead to longer lead times or the need to “field apply” coatings prior to installation. By receiving the manufacturer training, Romtec Utilities can now speed up this coating process by completing it during the well prefabrication and assembly. This provides an application process with a higher degree of quality control and less disruptive variables like weather.

Romtec Utilities is always improving our pumping system product offering to provide our customers with the best systems available. By learning this 3-part coating application method, our customers can get a new option for wet well coatings that are applied in a quality controlled environment and delivered onsite ready for installation. In addition to liners and other coasting systems, this Tnemec system is great offering for any wastewater and sewer application. Call our sales team today to learn more about coatings and liners and all of our pumping system products!