Determining The Right Pumps

There is no one size fits all when it comes to choosing the right pumps for your pumping system. Different pumps and pumping manufacturers fit best for different pumping scenarios and system configurations. That’s why Romtec Utilities works with all brands and manufacturers. We know that no one brand has the best pump for every system and different system configurations require different pumps. The following is a review of the different types of pumps and where they best fit the project.

Submersible pumps are the “go to” pump for moving stormwater and wastewater around the world. They are designed to be “submersed” in the liquid they are pumping. Submersible pumps can be anywhere from five gallons per minute all the way up to several thousand gallons a minute and everything in between. The only real limiting factor for submersible pumps is the head they will overcome, which is due to the impellers that are used.

Solids-handling pumps are the backbone of the wastewater and stormwater conveyance world. Solids-handling pumps are a centrifugal end-suction pump design. They combine a volute-type casing and an impeller with large internal clearances designed to pass the type of solids commonly seen in wastewater and stormwater. Solids-handling pumps cover the widest operating range of any submersible pump type.

Chopper or Cutter pumps are macerating centrifugal pumps that are design to be used in tough, high-solids pumping applications. Chopper or cutter pumps are solids handling pumps that have additional “blades” to cut large solids into smaller pieces, usually less than 3” in size. Chopper pumps and cutter pumps can pump large ranges of flow, making these pumps suitable for a wide range of applications. Chopper pumps are ideal for schools, prisons, sports stadiums, and hospitals which all have tough wastewater pump environments.

Grinder pumps are best applied to low flow/high head/low solids pumping applications. A submersible grinder pump grinds all the wastewater as it enters the pump into a slurry. The opening for these pumps is less than ½” in diameter. Because the opening is so small, the grinder pump must grind all the material into fine slurry containing no solids. Overall, grinder pumps have a great name, but tend to struggle with clogging issues.

Axial flow (propeller) pumps are ideally suited for use in high flow/low head applications. They are the “go to” pump for flood control around the world. They work much like a boat propeller with the blades of the propeller actually moving the water. The propellers have pitched blades that can be adjusted to displace water at specific flow rates as opposed to generating pressure that centrifugal pumps require. This is what makes them more effective at handling high-flow requirements. If the intent is to move thousands of gallons of water in a low head scenario, then axial flow pumps are the solution.

Self-priming pumps, sometimes known as horizontal self-priming pumps or horizontal centrifugal self-priming pumps, are designed to work above-ground, in a clean and safe location above the wet well and liquid, while providing all the performance required for tough pumping applications. Self-priming pumps are limited on the depth of the wet well that they can be used on due to the “suction” they create to lift the liquid to the surface.

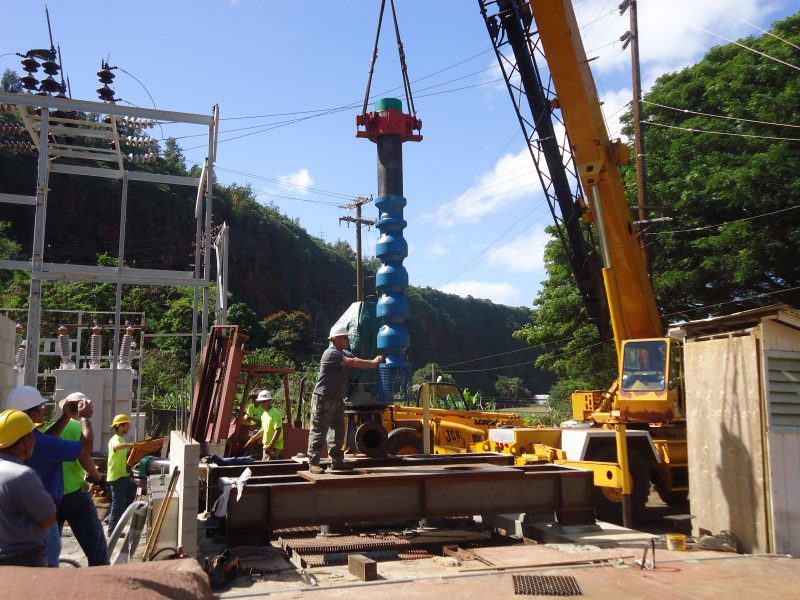

Vertical Turbine pumps are ideal for high flow, high head, clean water scenarios such as irrigation, industrial process water and, potable water. Vertical Turbine pumps work on the same principals as a centrifugal pump with multiple impellers and “bowls” to increase the pressure the pumps will overcome. Vertical turbine pumps come in several different configurations, lengths, and materials of construction which offers design flexibility for clean water pumping applications.

Vertical Wet-Well pumps are ideal for industrial wastewater/stormwater applications in which solids are present in the pumping liquid, but the liquid may be corrosive or contain some hydrocarbons. Vertical Wet-Well pumps are centrifugal pumps where the volute and impeller are immersed in the pumping media and the motor sets at ground level with a column and shaft connecting the two. This keeps the electric motor out of the possible corrosive or oily water. They are still capable of handling solids as they are designed with solids handling impellers.

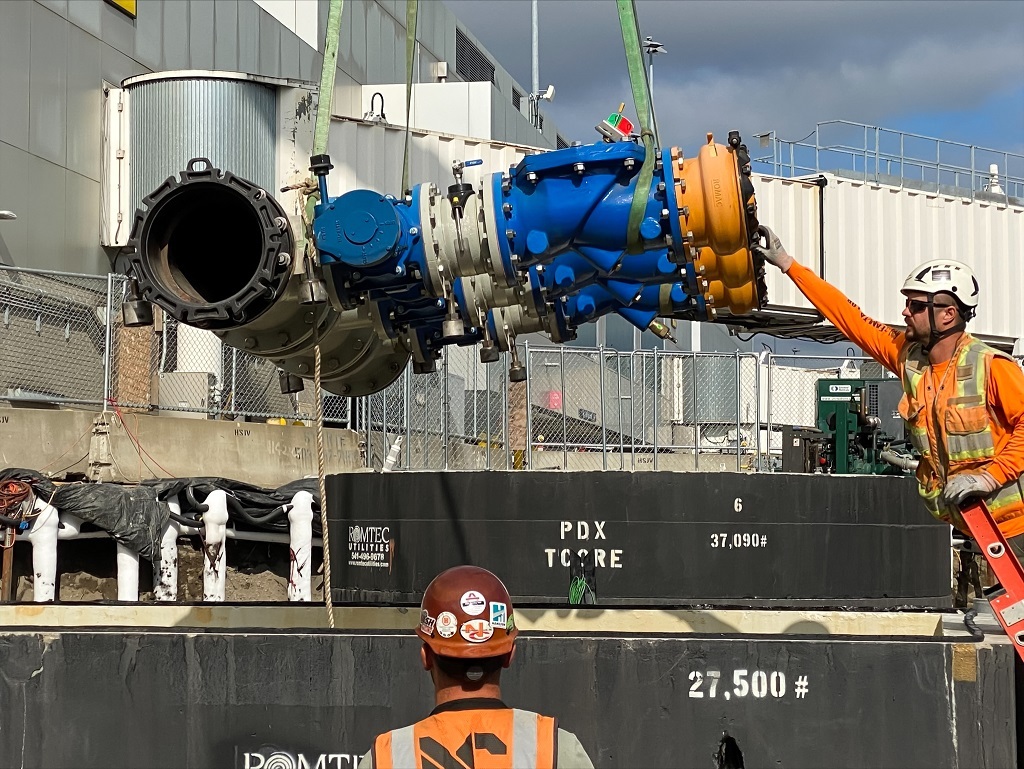

Inline Turbine pumps are perfectly suited for clean water pumping scenarios such as irrigation, industrial process water and, potable water. Inline Turbine pumps work on the same principals as a centrifugal pump or Vertical Turbine pumps with multiple impellers and “bowls” to increase the pressure the pumps will overcome. While the intake portion of Vertical Turbine pumps are typically submerged in the liquid they are pumping, Inline Turbine pumps are mounted “inline” with the intake and discharge piping. Inline Turbine pumps are perfect for potable water and irrigation “booster” systems as they can be easily skid mounted for ease of installation.

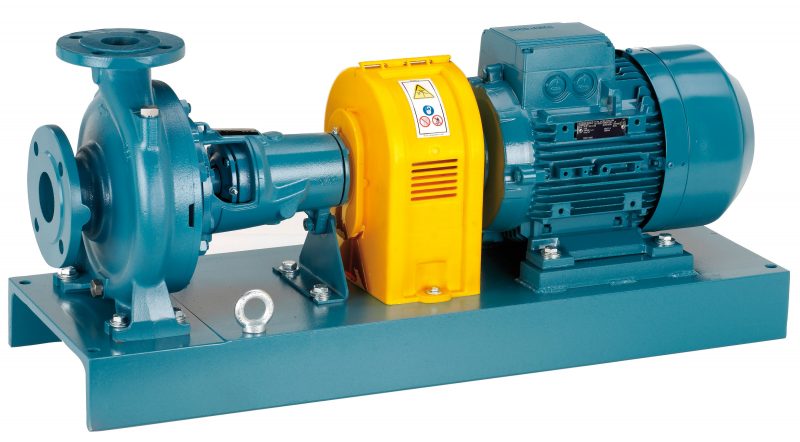

End Suction Centrifugal pumps are one of the most relied upon pumps on the world of water conveyance. They are used in every industry that requires the moving of water. End Suction Centrifugal pumps come as small as 1/10th of a horsepower all the way into the thousands of horsepower. Romtec Utilities utilizes End Suction Centrifugal pumps in clean water applications like booster stations and water reuse systems.

Split Case Centrifugal pumps are extremely robust pumps that are used to pump water in above grade applications. Like End Suction Centrifugal pumps, they are used in every industry that requires the moving of water. Split Case Centrifugal pumps are typical horizontally mounted with large electric motors attached to “drive” the pump. Split Case Centrifugal pumps are extremely common in industrial applications as well as fire protection pumps.

Subscribe to Our Newsletter Today!

Sign up today to receive exclusive product updates and offers.

How Can We Help?

Subscribe to Our Newsletter Today!

Sign up today to receive exclusive product updates and offers.