Romtec Utilities offers pump and lift station systems with all structural, mechanical, electrical, and communication systems included from design on through start-up and warranty. One scenario that is fairly common is that during the design of a submersible pumping system a customer will request certain components be housed in the wet well. These requests are typically made to adhere to existing design standards or to increase the cost effectiveness of the system design. Romtec Utilities advocates for utilizing submersible pump system design practices that prevent dangerous conditions, like housing equipment in the wet well.

All of our customers are concerned with safety because in-ground, submersible pumping systems have a history of incident for injury and accidents. The most common accidents involve falling and loss of consciousness from exposure to H2S gasses from sewage. In many cases, accidents in these circumstances aren’t caused by negligence or hazardous behaviors. Often times personnel are simply performing routine work and one detail goes wrong. Over the years, submersible pump station engineering has improved to the point where most risks associated with injury and accident can be completely avoided.

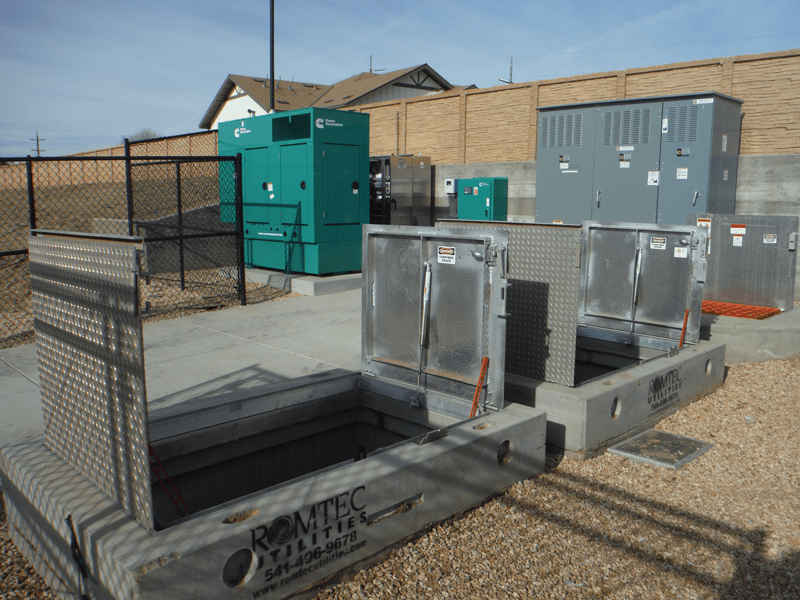

The first engineering detail is a simple one that we hinted at earlier: keep components out of the wet well. Although pumps and piping must be in the wet well in a submersible system configuration, many other components can be located outside of the well. Valves, meters, level sensing, electrical access, and much more can all be located outside of the well. By placing these components outside of the well, maintenance personnel will conduct maintenance work on these components outside of the well. This fact alone will remove a major source of potential incidents. Removing components is one of the best strategies, but since some components must be in the well in a submersible pump station, other design strategies must be used.

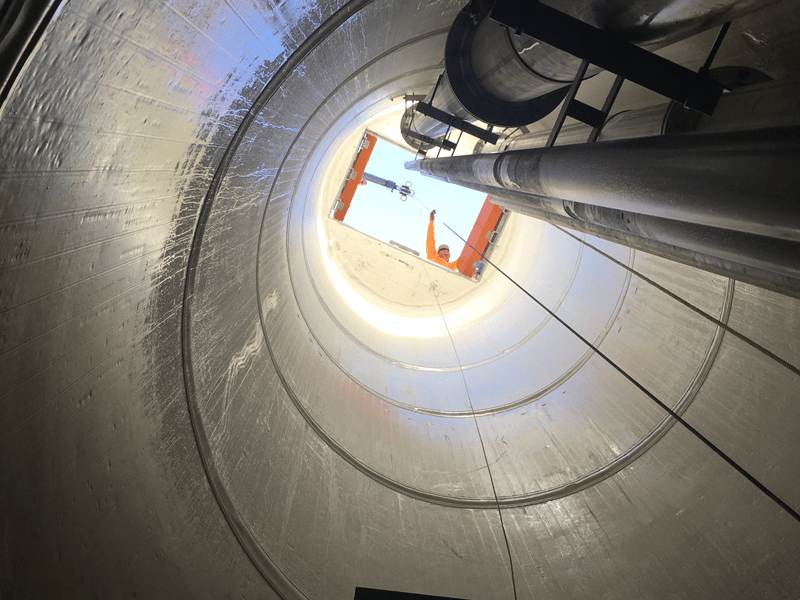

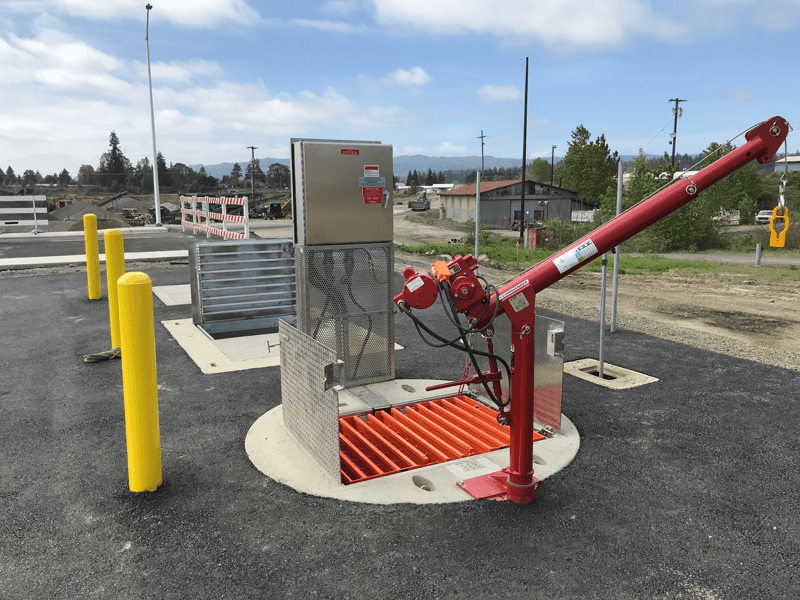

Many existing pump stations from previous design eras include features that almost encourage access to the well. These features include components like ladders, blowers/fans, and rigging. Romtec Utilities typically provides only equipment that enhances safety as opposed to equipment which may create a false sense of safety. Eliminating the ladder is a big decision, but above any other equipment, this prevents most personnel from considering entering the confined space of a well. Other components like hatch safety grates and cranes make it possible to view the well interior and remove the pumps with minimal exposure to risk of falling. Engineering a submersible pump station with modern components while eliminating more dated methods is a great benefit to safety for these pump stations.

Customers always prioritize the safety of their personnel, but they are not always aware of the best modern practices and configurations available. Romtec Utilities specializes in the design and engineering of pump and lift station systems. This expertise gives our staff a great insight for clients into how to create a modern and safe pump station in a submersible configuration. Our sales team and engineers work to provide education and documentation for the components we recommend in a safe submersible pump station with limited risk for accident and injury.