Romtec Utilities designs, manufactures, and supplies pump stations for all types of applications, including all structural, all mechanical, all electrical, and all communications systems. Pump stations are designed to handle many different types of water, and some water types create hazardous conditions. These conditions are regulated as classified spaces based on several criteria. The best practice for handling hazardous conditions is to avoid contact with them as much as possible. Romtec Utilities always designs pump and lift stations with safety as an utmost consideration, and avoiding hazardous conditions is should be a priority for any pump system design.

The first thing to understand is what causes a hazardous condition with a pumping system. Hazardous conditions are defined by regulatory agencies like the National Fire Protection Agency (NFPA) and the National Electric Code (NEC). These definitions describe conditions where dust and vapor concentrations are hazardous for causing explosions in the presence of electrical equipment capable of generating a spark. For pumping systems, this is almost always related to vapors that are created from the liquids being pumped. In sewer applications, hydrogen sulfide gas (H2S) is a byproduct of sewage. Wherever sewage is contained in a closed atmosphere, like a well or manhole, a hazardous condition – as defined by these regulatory agencies – is created.

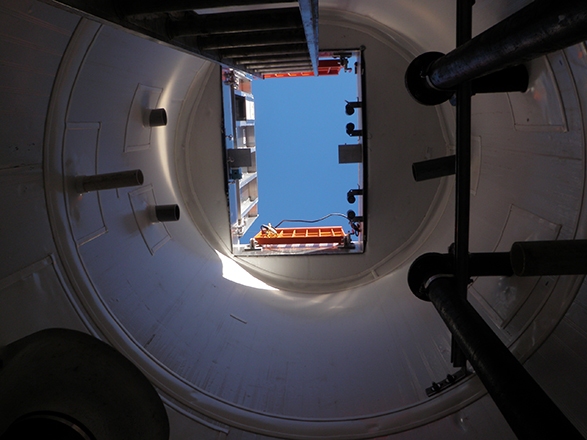

For the NFPA and the NEC, defining a hazardous location is directly related to the regulation of installing and operating electrical equipment, meaning these definitions do not regulate accessibility to these locations. Since a hazardous location is defined by potentially dangerous concentrations of vapors and dust particles, these same qualities can pose as much danger to human occupants as they can toward explosive potential. Instead, hazardous locations are typically also defined as a confined space. Confined spaces have limited access for entry or egress and are not designed for occupancy. Access to a confined space may require specific precaution, but typically it is not outright denied.

Due to this fact, the design of a pumping system can facilitate or impede access to a confined space. For example, a wet-dry system configuration installed in a below-grade application makes it necessary for personnel to enter a confined and potentially hazardous space. If a wet-dry configuration is absolutely required, then blowers and other precautions should always be included to prevent accidents related to a hazardous environment. Romtec Utilities advocates for pump station designs that never or rarely require entry to a confined or hazardous space. There are several design practices that are typical in our systems to help improve the safety of these systems.

The first design feature that is typical to prevent access to a confined space or hazardous condition is the absence of ladders. Unless it is required, Romtec Utilities will not include ladders in a pump station design. Instead, our pumping systems are designed to be maintained and operated entirely above-grade. The lack of ladders prevents any attempt from entering the space. Second, Romtec Utilities will locate most system components outside of the confines of a hazardous location like the wet well. For components like valves, meters, and pumping ports, maintenance can be required at times. By removing these components from the wet well, it also removes them from a hazardous location.

In certain circumstances like with clean water or stormwater, the likelihood for hazardous conditions is much lower, and these types of design considerations have less impact on the overall safety of the pumping system. Additionally, if access to these areas cannot be avoided, such as by size limitations of the site, Romtec Utilities can include traditional safety options like blower systems, lockout/tagout options, and other such methodologies. The best practice, however, is to avoid access to these locations at any time.

Pump stations serve an important role in American infrastructure, and there are millions of them across the country. A sad fact has been that poor design and training have caused personal injuries and even fatalities to personnel that operate these systems. Romtec Utilities places safety as a top priority in the design of any pumping system. Preventing access to hazardous conditions and confined spaces is a great safety advantage whenever it is possible. For more information about our pump station design philosophies or our safety features, contact Romtec Utilities.