News & Stories from Romtec Utilities

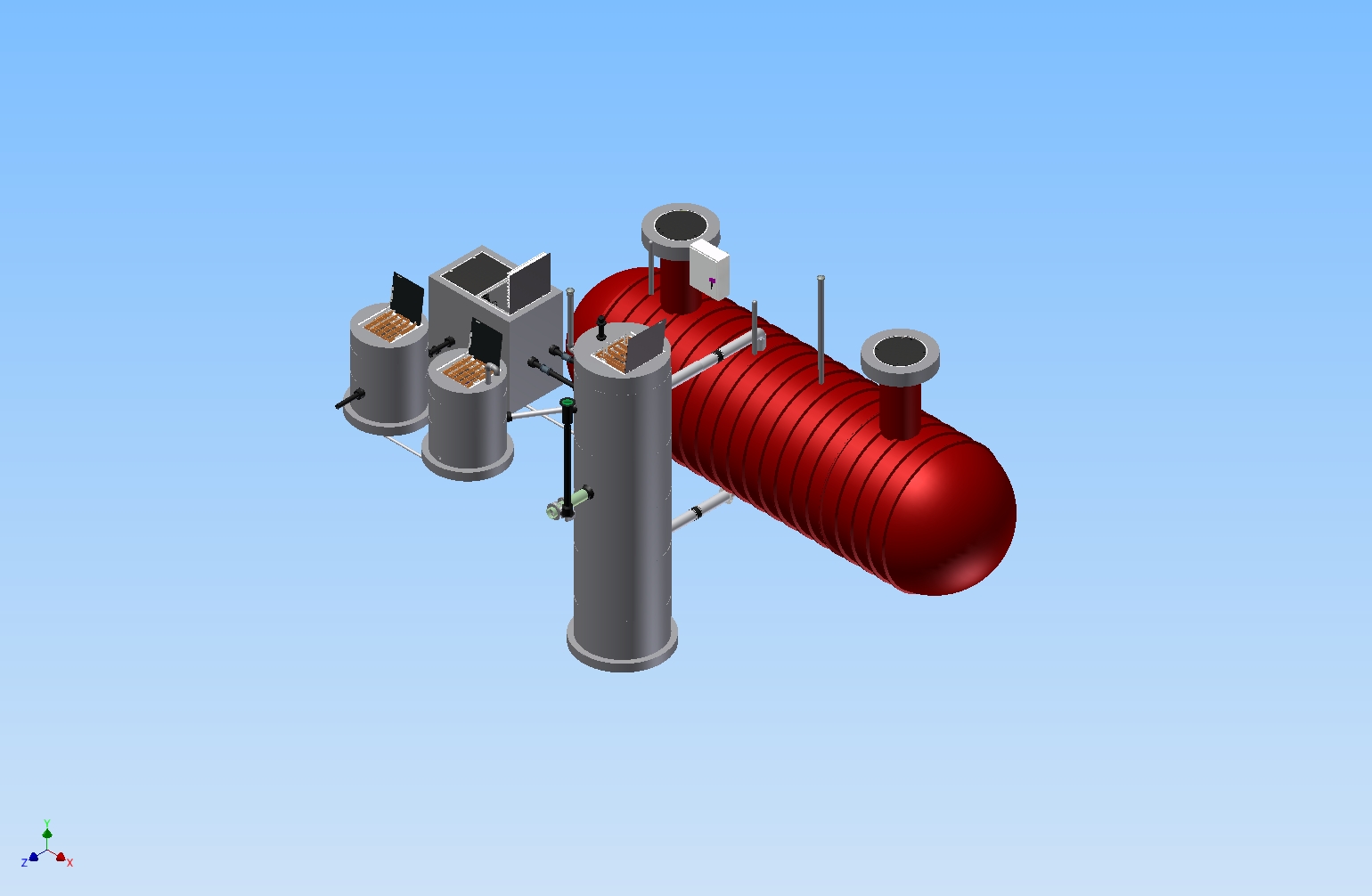

Romtec Utilities is always working to provide new and useful web content for our visitors and customers, and one of these new features is the ability to search projects as skid-mounted systems. These are complete pump stations that are mounted on prefabricated steel “skids,” so the pump station can be mobile, surface mounted, or used to retrofit an existing sump. The uses of skid-mounted pump stations vary greatly between water types, applications, sizes, and sophistication.

Romtec Utilities typically tries to reduce the amount of components located in the wet well on new lift station designs. Keeping the wet well clear from too many components will decrease maintenance concerns and improve the functionality of the system, but there are some components that will improve the wet well functions when included. In a lift station design for wastewater, it is important to understand what components to include in the wet well or

In frequent scenarios, lift stations are subjected to varying peaks of inflowing water and wastewater. There are different reasons for why these varying flow rates occur, but one simple and widespread solution is the overflow tank. Romtec Utilities works with customers to find the best approach for their packaged lift station project to select and purchase an appropriate overflow tank. Overflow tanks are relatively simple components. Some engineers will simply refer to them as storage

Romtec Utilities designs pumps stations with jockey pumps for every major water type –wastewater, stormwater, industrial water, & clean water. Jockey pumps in pump stations are small, typically low horsepower, pumps that operate regularly to handle nuisance flows in a system designed for larger peak pumping rates. This allows the pump station to handle a very wide range of flow rates without increasing the wear on the large horsepower pumps. Each jockey pump application typically

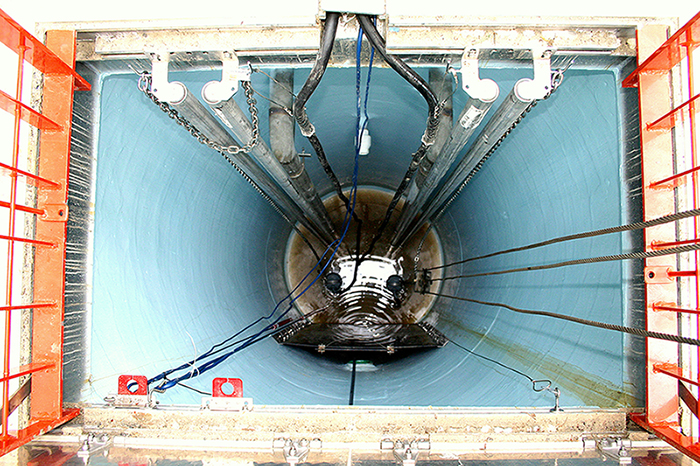

Installing an Ameron Liner Precast concrete components, such as wet wells or manholes, have the potential to encounter corrosive elements in water. There are several methods of protecting concrete components for particular site specific conditions. Corrosive elements are typically known when dealing with a specific water type or circumstance. Hydrogen Sulfide is typically a byproduct in wastewater –especially in hotter climates, while industrial water processing can be caustic or acidic. All of these instances can