News & Stories from Romtec Utilities

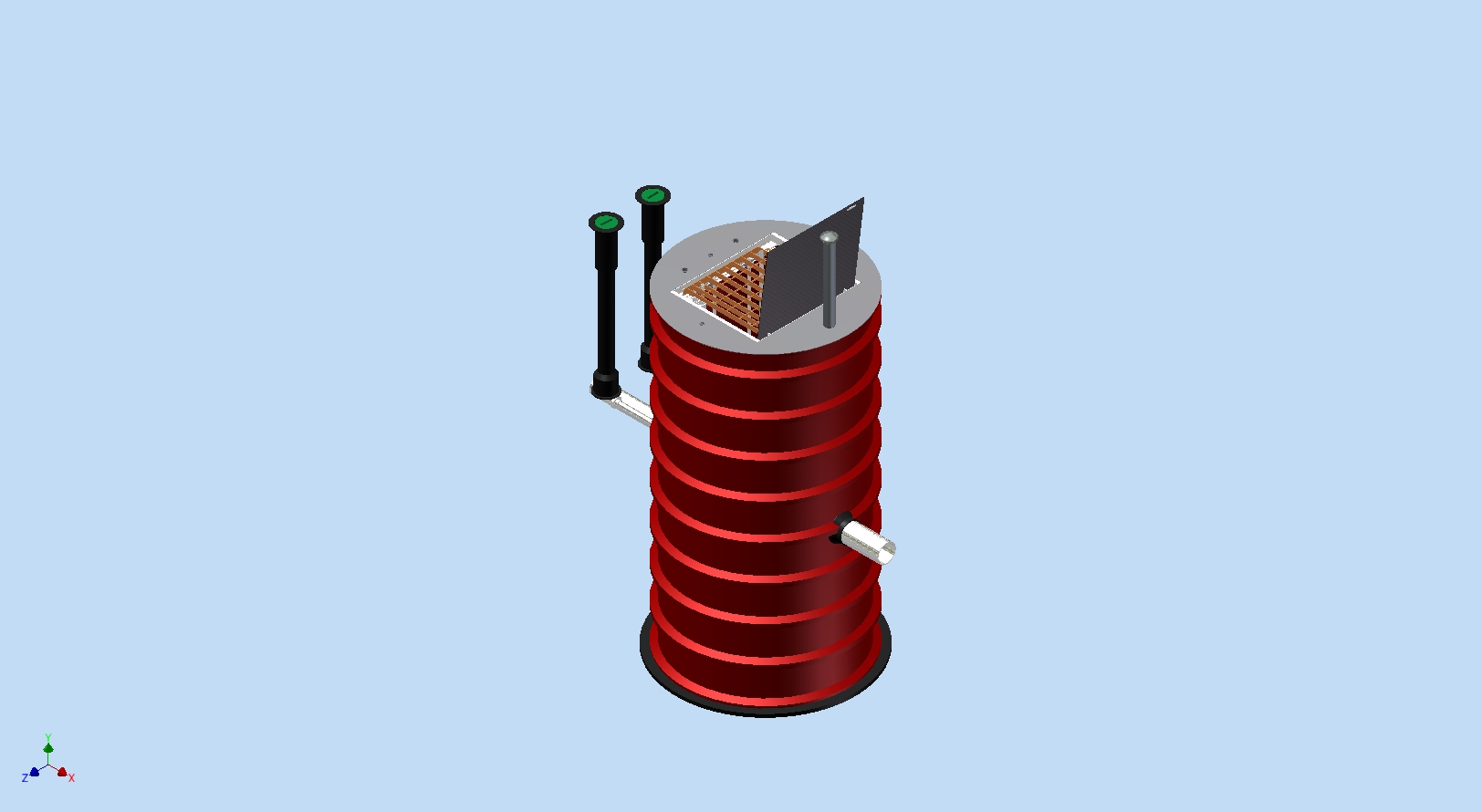

Romtec Utilities designs pump and lift station systems with true double-wall sumps and leak detection, sometimes known as secondary containment tanks. Lift stations with these sumps are extremely robust and are suitable for hazardous water types, corrosive liquids, and regulated environmental locations. Romtec Utilities has worked on several recent projects that required double-wall wet wells and suggests this type of wet well structure for any environmentally sensitive liquids or other sensitive water containment requirements. Romtec

Romtec Utilities designs many different types of odor control systems for wastewater lift stations. Although there are a lot of odor control technologies available, there are two main thoughts behind odor control for wastewater. The first thought is referred to at Romtec Utilities as “passive odor control.” The second thought is referred to as “chemical feed systems.” These two ideas are not simply a breakdown of different technologies; they represent two different cultures of wastewater

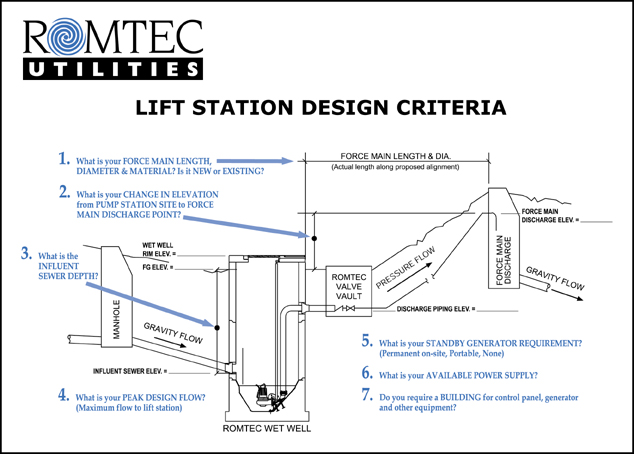

Each lift station project is unique. Whether you are pumping wastewater, stormwater, industrial water, or clean water, Romtec Utilities provides expert design services for every type of pumping application. Our design services go beyond simply meeting pumping requirements, design criteria, and design standards. With Romtec Utilities, you get an experienced company that knows how to design lift stations in wide-ranging circumstances. Many lift station designs are created by working with multiple agencies, solving unique water

Check valves are an important component of any lift station design. Without check valves, the pumps and wet well of a lift station can be subject to damage from backflow. Backflow occurs when the lift station pumps stop operating and the water in the force main and discharge piping flows back into the wet well. In virtually every case, the backflow creates high levels of hydraulic pressure that pumps and wet wells are not designed

Heat tracing is the practice of applying a heating line and insulation to piping. This is done in very cold climates where there is a possibility of the pipes becoming frozen. Romtec Utilities recently applied heat tracing to the piping and valves in eight vault structures on both stormwater and wastewater lift stations installed at the Union Pacific Railroad (UPRR) in Cheyenne, Wyoming. Typically, locating the piping and associated mechanical components in an in-ground vault

Comments 1

Have a chemical wastewater transfer project that requires secondary containment pump stations. Please send the specs for the product line and chemical resistance.. The wastewater pH varies between 2 and 14.

Thanks!

Nick