British Petroleum Cherry Point Refinery, Birch Bay, Washington

Project Details:

British Petroleum’s Cherry Point Refinery is located near Birch Bay, WA and is less than a mile from the Salish Sea shoreline. It is the biggest oil refinery in the State of Washington, producing as many as a quarter of a million barrels per day. To address runoff concerns, Cherry Point purchased a Romtec Utilities stormwater pump station.

According to the Cherry Point Refinery Environmental Policy, Cherry Point recognizes and is committed to the protection and respect of the environment where the refinery operates. The majority of the refinery’s impervious surfaces drain into an on-site wastewater treatment center, but part of the refinery was not draining into that system.

The refinery is located near two important natural habitats, Birch Bay State Park and the Strait of Juan de Fuca. It is also less than 1000 feet from Terrell Creek, which flows into the park, and less than a mile from the shoreline. With these prominent recreation areas and habitats nearby, adding a robust pump station was needed to handle the stormwater runoff.

With Romtec Utilities, Jacob’s Engineering, and the Cherry Point Refinery, a dependable solution was developed to solve the industrial stormwater runoff concerns at this oil refinery. In addition to a stormwater pump station, semi-impervious gravel areas would be resurfaced to drain more effectively and limit the concentration of suspended dirt particles in the water.

Documentation:

Romtec Utilities Scope of Work:

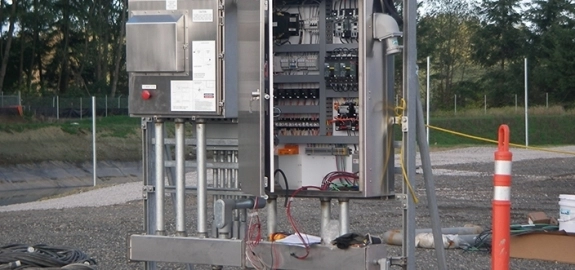

Romtec Utilities started by working with Jacob’s Engineering out of Bellevue, WA to design the Cherry Point stormwater pump station. Jacob’s engineering supplied Romtec Utilities with information about the job site and the pump station requirements. A major part of the design of this pump station was that it required a high degree of redundancy, from pumps to controls.

The level of backup systems on this pump station is not typical for stormwater systems, but the BP managers at Cherry Point realized the importance of eliminating any possibility of oil and gas pollution. The primary level sensing device was a set of mechanical floats. The system included backup level sensing with an ultrasonic transducer that was prefabricated into the top slab of the wet well. The ultrasonic device also served as redundant controls for the pump station.

The pumping system was designed with submersible Flygt pumps in a duplex configuration. Duplex configurations are typically used as a failsafe in case one pump fails during a pumping cycle. With stormwater, an overflow scenario is not typically as problematic as with sewage, but the Cherry Point Refinery valued installing a system that would protect the environment even in unlikely circumstances.

Romtec Utilities designed, manufactured, and supplied the complete stormwater pump station and delivered the ready-to-install packaged pumping system to the Cherry Point Refinery. IMCO General Construction was the installing contractor for the pumping system, as well as other utilities and on-site structural work. Romtec Utilities provided an onsite technician to help advise on the installation of the pump station and to provide experience with the included Romtec Utilities system documentation.

The end result was a stormwater pump station that was completely designed and engineered for long-term operation with little to no concern for overflow. This pump station serves as an integral part of the stormwater management plan for this BP refinery. The specified ad included redundancy of this system ensures that the stormwater runoff from this refinery does not pose a risk to the nearby environment.