Romtec Utilities designs, engineers, manufacturers, and supplies lift stations for all types of application with all structural, mechanical, electrical, and communication systems included. One feature included on many different pumping systems is the auxiliary vault structure. Vault assemblies comprise components such as valves, meters, air release valves, pressure relief valves, pumping ports, pigging ports, and other components. Getting a good vault structure for your auxiliary systems can be a key aspect of a good pump station. Here are a few engineering topics to consider when getting a new vault assembly.

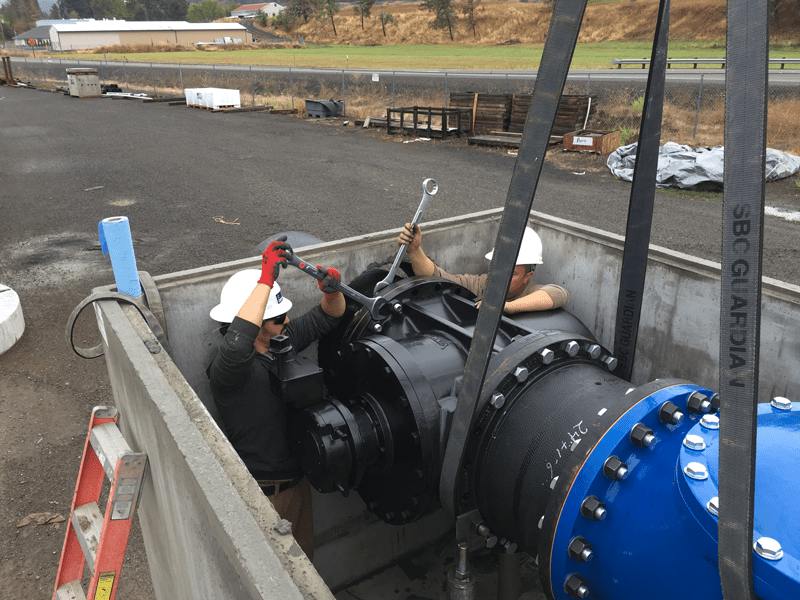

The primary benefit for using an auxiliary vault is that it is separate and easier/safer to access than the well structure. One of the foremost goals for a good vault structure is access for personnel. To retain this benefit, vault structures should be engineered with accessibility in mind. Components that can be safely located in a vault are extremely varied in size, operation, and maintenance requirements. It is difficult to take a “one size fits all” approach for accessibility. Larger pipe diameters, operating mechanisms, heat tracing, and other aspects can all affect how a vault structure is accessible to personnel.

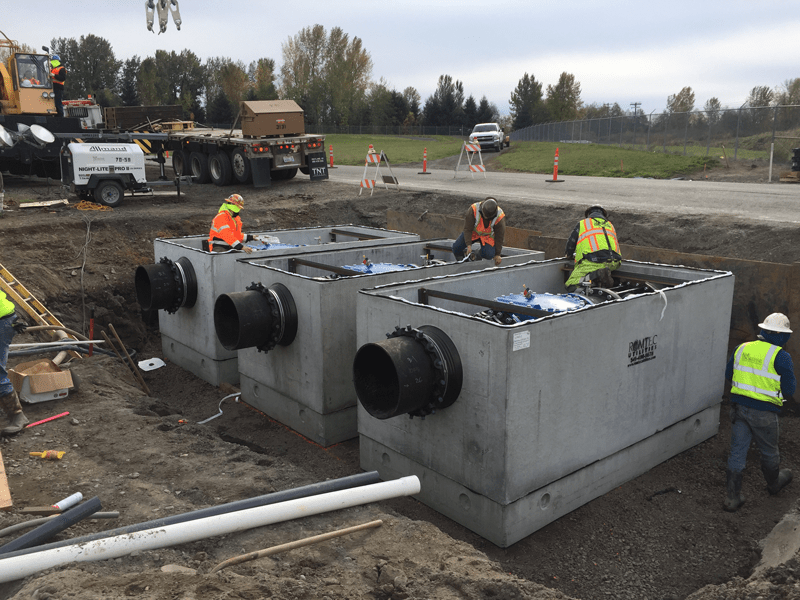

Another important consideration during the design is what should and should not go into a vault structure. Vault structures from materials like precast concrete and steel get exponentially more expensive the larger they get. This is also true for installation costs. At a certain point, the number of components that can go into a vault structure while still being accessible and affordable start to not make sense. In these circumstances, it almost always makes more sense to distribute components into two or more smaller vaults. This allows for a good vault layout where components are accessible and easy to maintain, and it also can reduce the costs of the individual valve assemblies.

Accessibility and cost are typically two of the driving factors behind engineering a good vault assembly. Another major consideration is the traffic rating for the structure and its access hatches. Vault assemblies can encounter a variety of traffic conditions from people walking to jumbo jets. In each case, the entire vault needs to be engineered to handle the weight load of the maximum anticipated traffic. This can increase the thickness of the walls, the amount of rebar or reinforcement used, and the robustness of the access hatches. Getting your vault assembly rated for the traffic on your site is a very important safety standard for engineering these assembly.

There are hundreds of additional things to consider as well. The size of your site will impact vault installation and configurations. Frost depth can determine requirements for heat tracing or insulation. A high water table might require considerations like interior/exterior coatings, well drains, or even sump pumps. No matter what situation is facing your vault, it is likely that Romtec Utilities has engineered an assembly to handle something similar. Contact us today to get a new vault assembly for any type of pump station componentry.