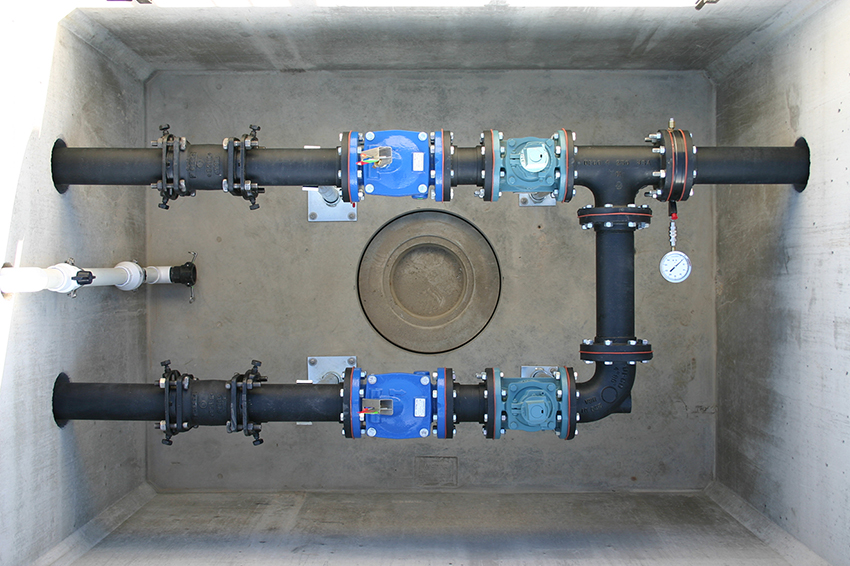

Romtec Utilities designs, manufactures and supplies complete pump and lift stations. Many of our systems are prefabricated at our manufacturing plant for easy delivery and installation. Often times these systems include mechanical components, such as valves vaults, meters vaults, and grinder vaults. When Romtec Utilities manufactures these components, the entire mechanical assembly undergoes pressure testing prior to delivery.

Pressure testing the mechanical assemblies is a key process that ensures each mechanical assembly is fully functional when it delivers. It provides the end owners with documented, tested, and warrantied components that guarantee a fully functional pump station. For contractors, it reduces the scope of work and required time onsite for installation. This makes the installation and construction process faster and simpler. The contractor simply needs to connect the vault and well structures together. There are still many responsibilities during installation, however.

On-site, the contract must make all of the connections as well as seal the penetrations to the wet well from the inlet and discharge piping. The complete wet well also must be sealed at its joints. Once the system is installed, this work must all be completed by the contractor. Romtec Utilities simply provides pressure testing on the vault assemblies to reduce the testing requirements during and after installation. These services reduce the overall work required during installation to simplify the process.

Another aspect to pressure testing is checking the functionality of the mechanical components before they ship. Testing for leaks is one aspect, but occasionally, components can arrive with a defect or fault that does not function properly. By pressure testing, Romtec Utilities can find and replace these components before the project ships to the job site. If these aren’t found ahead of time, these issues are discovered at the job site and can cause lengthy delays to order replacement parts. Romtec Utilities saves everyone time by installing this components and testing them long before they deliver.

Romtec Utilities works every day to design, engineering, manufacture, and (most importantly) deliver reliable pump stations. Pressure testing the pump station mechanical assemblies is just aspect of what we do to provide high-quality and fully functional pump stations. Contact Romtec Utilities today to learn more about our pump stations designed for virtually any pumping application.