Romtec Utilities designs and supplies pumping systems for many different applications, and it is common to include features like weir walls and baffle walls. These features are the most common in stormwater pumping, but other water types can benefit from these features if there are suspended solids or if turbidity will have a negative impact on the system components. These features are intended to slow the flow of water down, either to let solids settle out or to prevent the water current from disrupting the functionality of the in-well components. These two features can be configured in many different ways to fit the specific needs of any customer in any location. There are many considerations when it comes to these features and it starts with the system requirements.

The site, water conditions, pumping requirements, and other system goals will all impact how weir walls and baffle walls are engineered. The most common scenario for a weir wall is to allow sediment to settle out of water. When a water inflow encounters a weir wall it slows down and must rise to overflow the wall. In this way, heavier solids that can damage pump components and piping (like sand and rocks) will settle out of the water. Baffles walls may have holes or gaps at the sides or bottom. These devices simply slow down the inflow. The pumps may easily be able to pump grit and sand, but the cables and housings maybe jostled loose by strong inflows. The goal with both features is to slow down water flows, and depending on the site, this may need to be accomplished in different wet well shapes and materials.

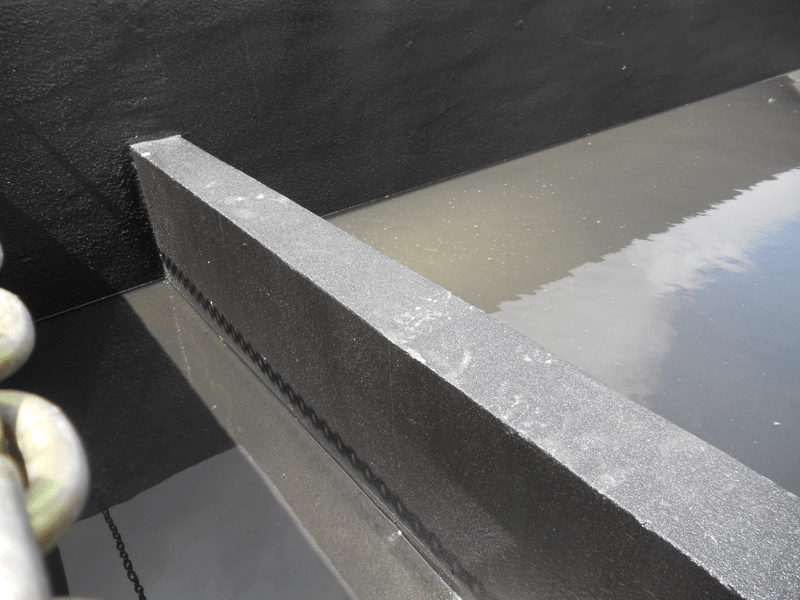

Wet wells can be fabricated from materials like precast concrete, stainless steel, HDPE, and other materials. Typically, wet wells are either round or rectangular. Depending on the needs of the project, there are certain things to consider. Round wet wells can easily include baffles. Romtec Utilities manufactures a component called a deflector panel that acts as a baffle for inflows. Weir walls are more common in rectangular sumps and wells, but they can be customized for unique applications as needed. Romtec Utilities has provided custom baffles and energy dissipaters on rectangular and circular wells, and we have fabricated weir walls on these structural shapes as well. In each instance, the material of the weir or baffle is also unique to the application.

The most common materials for weir walls and baffle walls are concrete and stainless steel. Concrete weir walls can be precast into the well structure or they can be added as an insert into the structure during installation. Stainless steel is almost always bolted onto a well structure of any material. Depending on the speed of the inflow current, the types of suspended solids, and the quality and chemistry of the water, weir walls and baffle walls can be engineered with any material that is suitable for the specific needs of the system. The key features are strength, durability, weight, cost, chemical resistance, and versatility. A good design will tailor your system to the right blend of these considerations.

Romtec Utilities has engineered, manufactured, supplied, and installed weir walls and baffle walls for many different types of systems. In addition to the these common considerations, Romtec Utilities also handles design features like access hatches for pumping out sediment and collected solids and even redirecting flows to secondary storage or overflow tanks. No matter what your pump station requires, Romtec Utilities can provide the best designs for weir walls and baffle walls in fully functional pump station system. Contact our sales team to learn more about these features and how they can benefit your pumping application.