Romtec Utilities primarily uses two materials for constructing wet wells and sumps: precast concrete and fiberglass. Often, these two materials are preferable to cast-in-place concrete because of the uniform quality, the speed of production, and the cost savings from mass production. These two materials also provide benefits over the other, but choosing one material will typically reflect specific design standards or the requirements of the site.

Precast concrete is a very strong and durable material, but it can be vulnerable at times to different chemicals and gasses that can effectively “eat” the concrete. In these circumstances, coatings or liners can be applied to the concrete to protect it. There are literally hundreds of materials, application styles, and brands of these coatings and linings. The key to choosing the correct style for any project is to use a known company with real experience and trustworthy product documentation. Romtec Utilities can always supply advice and/or references for these types of wet well protection.

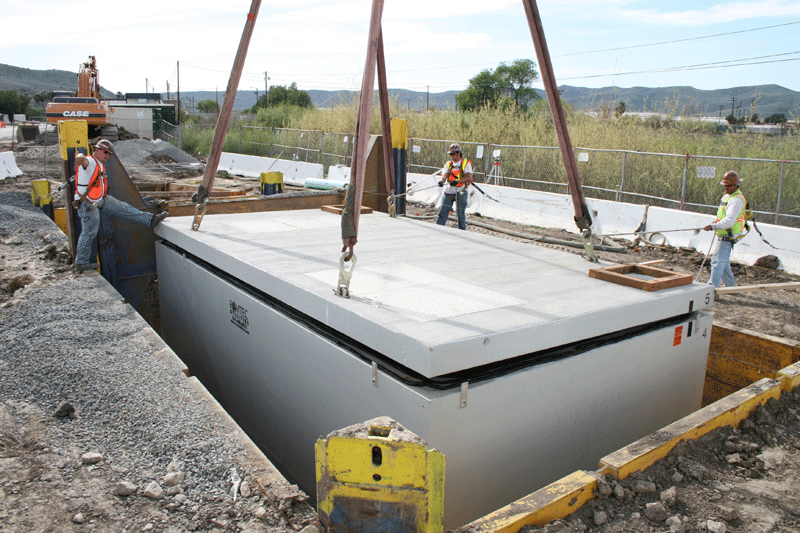

Precast concrete is flexible in its potential uses. Primarily, Romtec Utilities uses cylindrical “barrels” to create round sumps and rectangular “risers” to form rectangular sumps. These two primary shapes provide a substantial amount of design capabilities for pump stations. These can be used for wet-dry configurations, valve/meter/grinder/pigging vaults, multi-stage pumping, and many, many more design options. Good fiberglass is typically available as a cylindrical tank, but there are rectangular tanks available that can be used for pump and lift stations.

One of the best design features of fiberglass is its ability to be manufactured with a double-wall and leak detection. Although it is possible to get these features with concrete and steel tanks, those materials do not compare to the reliability and cost of the fiberglass tanks. Double-wall fiberglass tanks provide a very robust wet well material. These tanks all but eliminate the concern for a wet well to leak or leach into the surrounding environment.

Fiberglass is a very versatile tank material. It can be manufactured to resist most chemicals and gasses, whereas concrete requires an additional applied material. Fiberglass is also very versatile in terms of its installation possibilities, meaning it is structurally possible to install a fiberglass tank vertically or horizontally. This expands the possibilities for configuring these tanks into a pump station configuration. The same tank could be configured horizontally for a shallow well or vertically for a deep well.

In very custom applications, cast-in-place concrete may be needed to meet the specific project requirements. However, cast-in-place concrete is subject to a variety of uncontrollable circumstances, such as weather, cure-time, quality control, and the contractor’s skill/experience. For applications that can make use of manufactured tank products, pump stations will benefit from a superior product that is typically faster and more affordable with precast concrete or fiberglass. Romtec Utilities can engineer pump and lift stations to function exactly as required by the customer, and we can also provide our experience and expertise to get the best wet well materials in precast concrete or fiberglass.

Comments 2

Pingback: ECONOMY

Pingback: Sig P938 Pistols