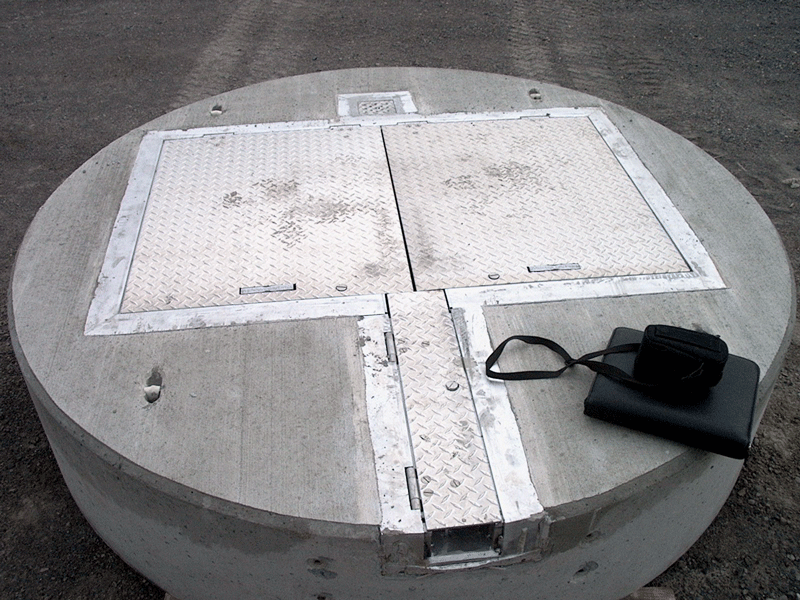

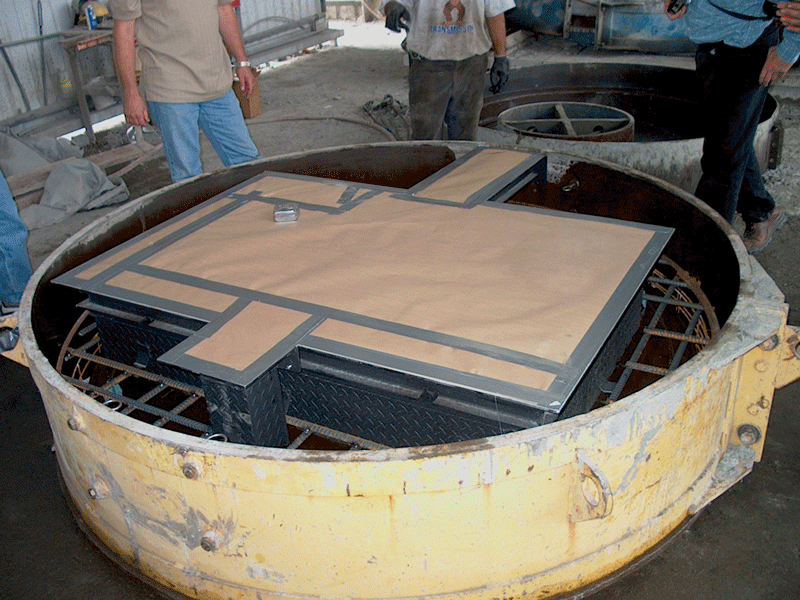

Romtec Utilities designs pump station retrofit packages for many different applications, from wastewater to booster pump stations. One frequent area of interest for pump station retrofit projects is replacing an aging hatch on the wet well and/or vault structures. There are many reasons to replace a hatch, but typically, the best solution is replacing the entire top slab for concrete wet wells or vault structures with the hatch. This type of retrofit process can tremendously extend the life and functionality of a wet well over simply fabricating a new hatch mounted to the existing well.

Hatches commonly need to be replaced. They can age, become damaged, or no longer function as intended, such as adding traffic rating requirements. However, the biggest concern with replacing hatches is typically a lack of reliable fall protection on the existing hatch. This is a big concern for lift station owners, and it can even be a requirement. A recent 5-year study from the Department of Labor found that 61% of confined space fatalities were a result of physical hazards like falling and only 33% were atmospheric like hydrogen sulfide exposure. With nearly 2 deaths occurring every week in confined spaces, providing reliable fall protection is a paramount consideration for retrofitting a wet well hatch.

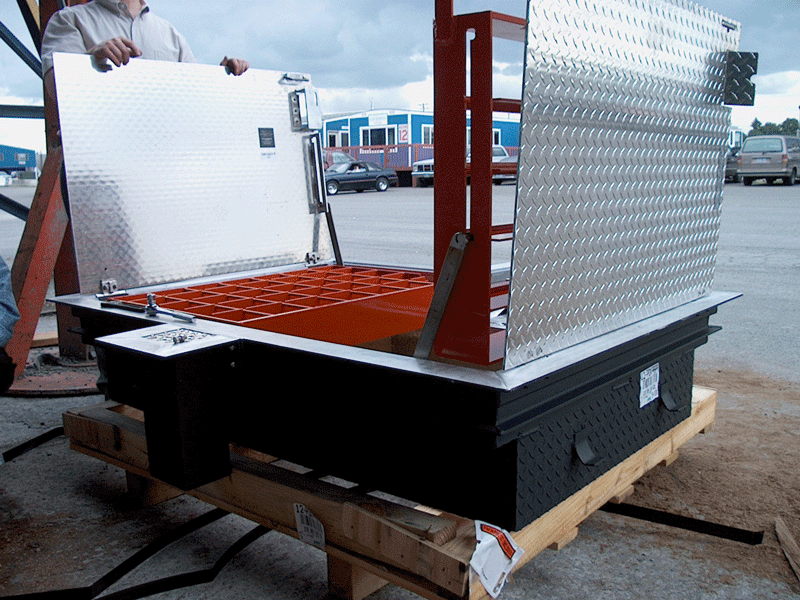

For any of the above scenarios, the best practice for a hatch replacement is to retrofit the entire top slab of the well. This is not only a best practice; it may be a requirement. Hatches in top slabs are engineered components. In order to provide reliable fall protection, the entire hatch needs to be engineered with a safety grate. Trying to add in nets and grates to an existing hatch is much less reliable as this process cannot be tested and does not have documentation per each specific application. Additionally if the hatch needs to be traffic rated, it is the entire structural unit that receives the rating, not simply the hatch.

Trying to “work around” these conditions will typically not meet the desired goals of a successful hatch retrofit. You could spend time and money and not receive reliable fall protection or a true traffic rating. When the entire top slab and hatch is retrofitted, it will meet these requirements every time. That is why Romtec Utilities approaches hatch retrofits and replacements by providing a site-specific design for your entire top slab component. This process can be approved by reviewers before anything is bought or installed so that you as a customer know that your project will be successful. Without engineering documentation specific to your site, it is possible to start a retrofit project with no clear definition of what the successful end product looks like.

Replacing a hatch can seem like a simple retrofit, and it should be. It is important, however, to realize that hatches are not simple “plug-and-play” devices. Hatches should have documentation, design drawings, and a proven manufacturer with a successful track record. Romtec Utilities provides these benefits on all of our retrofit project for hatches or complete systems. If you need a hatch replacement or retrofit, contact Romtec Utilities to see what will work best for your project.