News & Stories from Romtec Utilities

Polymer Concrete vs. Fiberglass and Traditional Concrete Wet Wells Polymer concrete, as covered in “Why Choose Polymer Concrete: The Benefits of Polymer Concrete Wet Wells”, is an alternative to traditional wet well materials such as precast concrete and fiberglass. Polymer wet wells combine many of the benefits of fiberglass and concrete, such as resistance to corrosion and workability, respectively. While Romtec Utilities does not design systems around any one product or material, polymer concrete is

A “Closed-Loop” Control Scheme The Town of Samoa is an unincorporated small community located on the Samoa Peninsula in the Humboldt Bay. The town is historically known for the Samoa Cookhouse that is “the last surviving cookhouse of the West” (Samoa Cookhouse). The restaurant also functions as a museum with pictures and artifacts from the history of the area, including logging and maritime ventures. The Town of Samoa is undergoing a large initiative to refresh

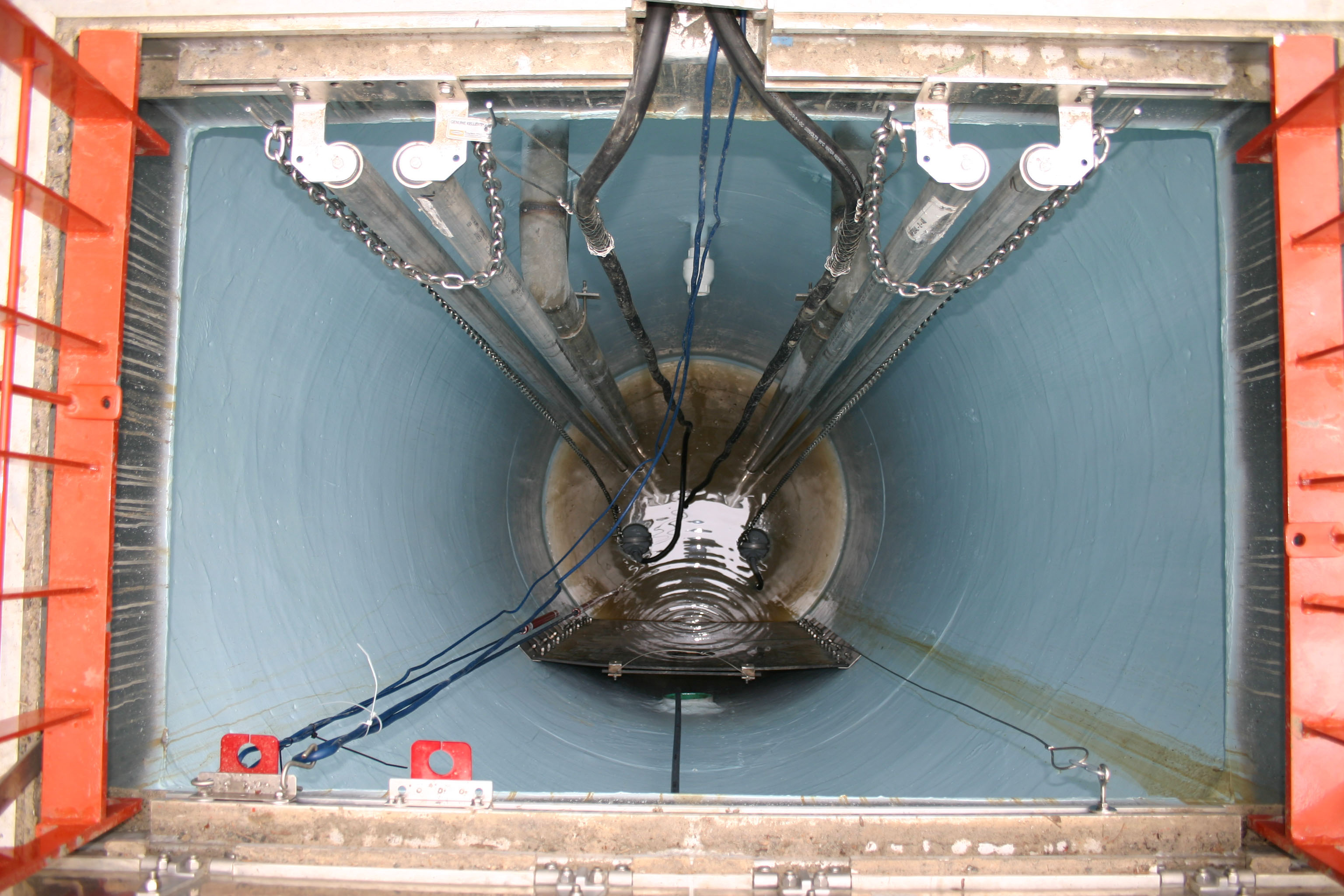

The Benefits of Polymer Concrete Wet Wells As long as human beings have elected to hold or store liquids in ground, they have struggled with identifying the best materials for the job. The chemical make-up of the liquids and related off gassing in lift stations require different types of materials for an overall successful design. At Romtec Utilities, we are faced with these types of scenarios every day and with our professional experience, we know

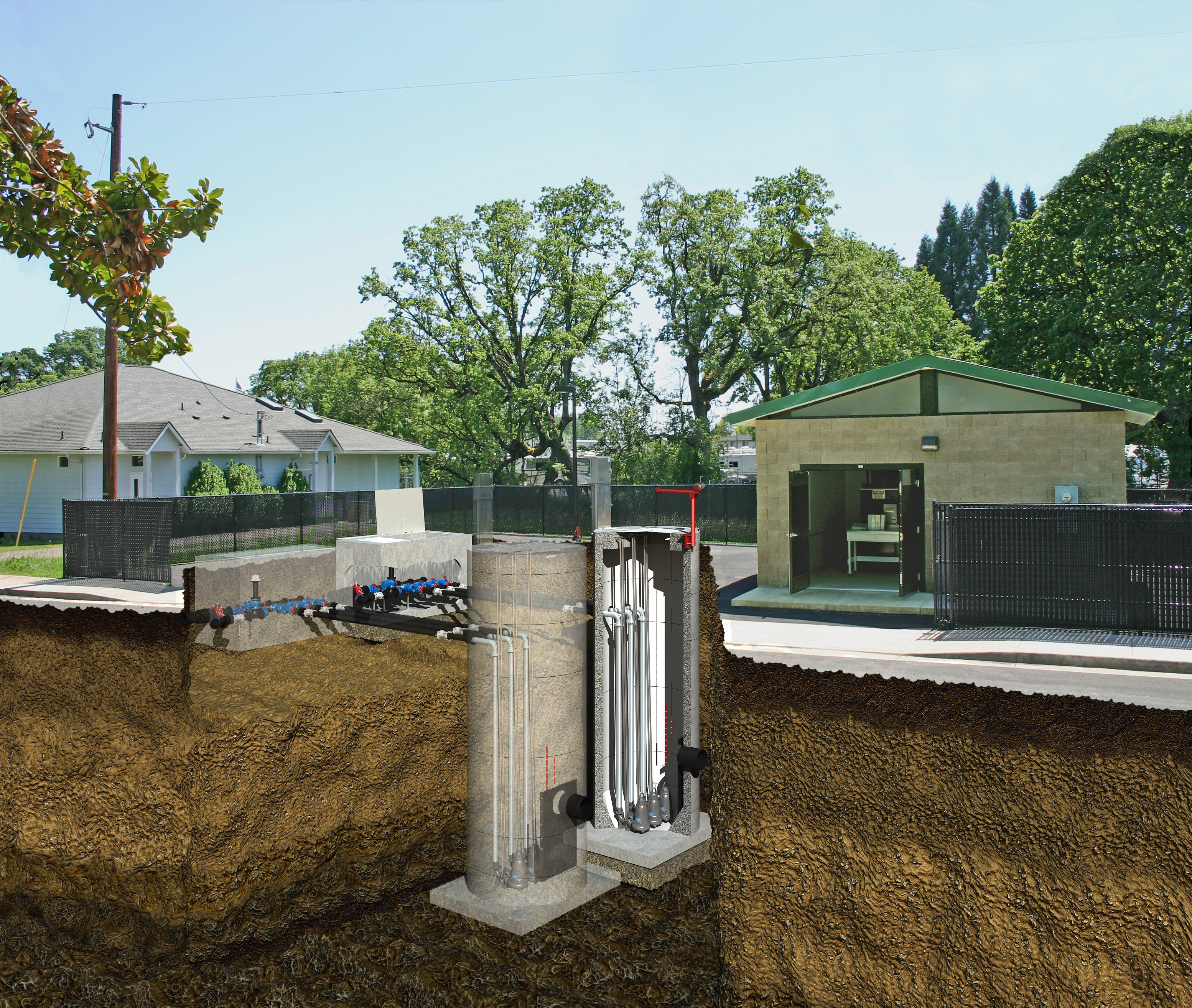

Romtec and Romtec Utilities Join Together For a Strategic Approach to the Laughlin Park Project The Laughlin Park project was a great opportunity for Romtec and Romtec Utilities combined, to demonstrate our respective fields of expertise. While the products from each company may differ, both companies supply important pieces of infrastructure around the nation. Romtec specializes in building design and supply with the capability to provide standard and custom buildings at a competitive price to

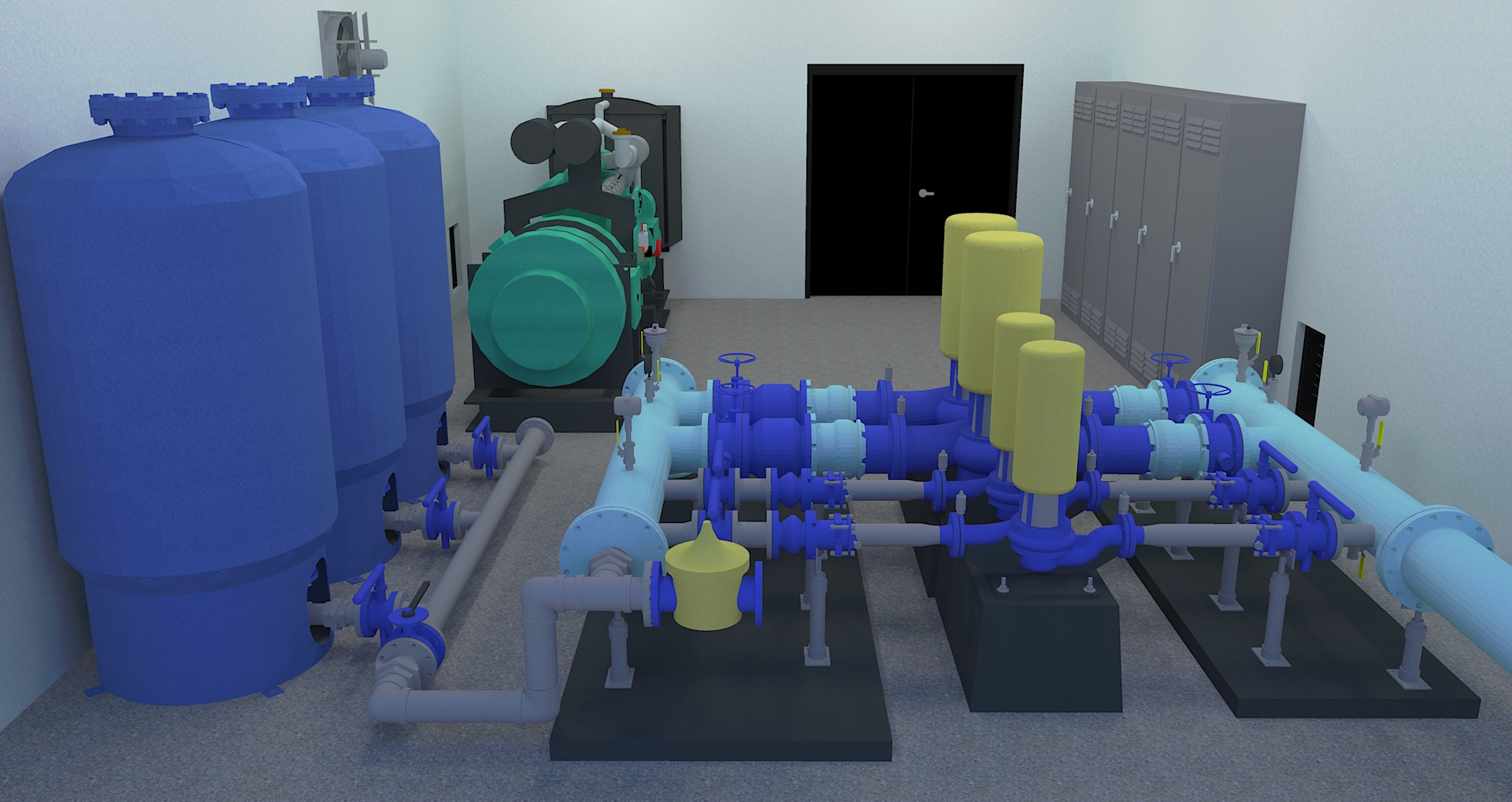

Pump Stations Designed For Current and Future Flows “Phased” (now and future flow) pump stations are common for large developments and ideal for situations in which the inflow to a lift station will increase over time. These types of systems are designed to run optimally at each phase. One might think that a large system designed to handle the maximum inflow found at full-buildout may be the best way to go. However, even though the