A “Closed-Loop” Control Scheme

The Town of Samoa is an unincorporated small community located on the Samoa Peninsula in the Humboldt Bay. The town is historically known for the Samoa Cookhouse that is “the last surviving cookhouse of the West” (Samoa Cookhouse). The restaurant also functions as a museum with pictures and artifacts from the history of the area, including logging and maritime ventures.

The Town of Samoa is undergoing a large initiative to refresh and revitalize the town to attract new residents and be officially established as a city. This project was started by the Samoa Pacific Group, a joint venture between multiple home builders that have teamed up for the overall project.

Samoa Pacific Group purchased the Town of Samoa in 2001, and is working with the government to fully establish Samoa as its own town. As an unincorporated community, the Town of Samoa is currently being governed by Humboldt County. To revive this area, multiple agencies are coming together to build a town square, pedestrian areas, new homes, and restore existing homes.

On the large encompassing project, development and project management was provided by the Danco Group; infrastructure design was by the California Engineering Company (CEC); reviewing was done by EsGil, on behalf of Humboldt County; and numerous others such as Aqua Sierra (Electrical Contractor) and Mercer-Frazer (Contractor) assisted.

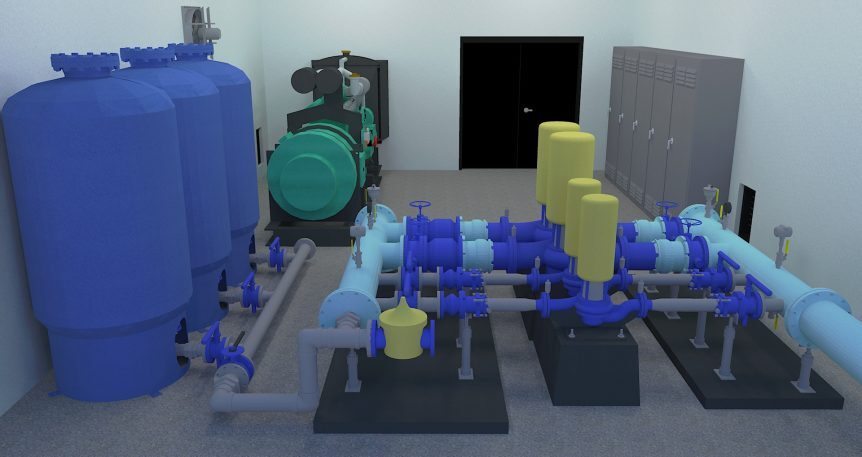

Romtec Utilities’ role in this project was the design and supply of a water booster station with an integrated building. The booster station pulls water from an adjacent 165,000-gallon water storage tank, and boosts flows for the domestic residences and fire hydrants. This high flow booster station uses three 264-gallon pressure tanks to prevent the system from short cycling during nuisance flow demands, and suppressing transient spikes in pressure. Because residential homes and fire hydrants rely on this booster station, an emergency generator was supplied to ensure that the booster station can serve residents during power outages.

The booster station will serve the mixed-use development of the town, and takes both domestic flow and “fire flow” into account. “Fire flow” comes into play when the discharge pressure drops dramatically from increased demand caused by hydrants and sprinklers during a fire. To accommodate the increased demand in water, larger pumps will be engaged to provide the pressure that the hydrants and sprinklers need. Domestic flow in this booster station will fluctuate within a specific range, and can typically be managed by smaller pumps.

To house the booster skid and the control panels, a control building was provided by Romtec Utilities’ sister company, Romtec, Inc. Romtec supplies structures such as restroom buildings and pavilions for parks and other public/private infrastructure. The Town of Samoa control building is designed to house and secure station components and take into account all working clearance requirements and safety precautions. Having a control building onsite prevents items like the control panel from being vandalized or damaged from weather.

The control panel on the Town of Samoa project is sophisticated and complex, and accommodates the booster station control scheme, the size of the system, and the ease of operation that will be required of the controls.

The control panel in this system is unique, and has been adapted by Romtec Utilities to incorporate the closed-loop control needed for this booster station. In the “closed-loop” control scheme, pressure transmitters are located at both the discharge and suction ends of the booster station to monitor the level/pressure of the supply as well as the level/pressure of the demand. As the discharge pressure decreases (showing an increase in demand) the system will begin to pump. More pumps will turn on as the demand continues to increase.

Romtec Utilities set the desired pressure in the system to meet our customers’ requirements, which will be maintained with PID (Proportional, Integral, Derivative) control. The use of VFDs to control the pumps is a very important process for PID control. VFDs match the speed of the pumps to optimize performance, and control the ramp-up or slowdown of the pumps. Often used in applications in which level needs to remain constant, the VFDs will increase the power to the pumps when demand is high, and decrease power when the demand is low.

Due to the size and sophistication of this system, the control panel is accompanied by a small Motor Control Center (MCC) that houses the Variable Frequency Drives (VFDs). The VFD’s are housed in the MCC in their own individual compartments to allow for better isolation of components and easier identification for maintenance purposes.

Booster stations and all of their components can be incredibly complex, with many unique factors at play for each situation. Regardless of how complex the system is, the end owner will need to be able to operate and maintain this system with ease. Rather than using third-party software, Romtec Utilities experts write all of the control panel software in house, and can cater the controls to suit the needs and the capabilities of our customer.

The Town of Samoa Booster Station plays an important role in the community, and ensures that residences have access to water. While many of us take water access for granted, it is an essential part of our infrastructure and our lives. The Town of Samoa is being revitalized and refreshed, and the Romtec Utilities booster station and control building will provide amenities for residents new and old.

Booster stations and lift stations can be very complex and incorporate the use of many different devices and components. Romtec Utilities has the expertise to provide complex customized systems with easy-to-understand control panels that fully suit the needs of both the pump system and our customers.

“Samoa Cookhouse”. www.visitredwoods.com. Retrieved 2021-03-30