In last week’s blog, the topic of water was discussed to show how different sources produce different water. Romtec Utilities understands that the source of water can have far reaching implications on a pump or lift station design. Wastewater was the main topic of the previous blog, but now we will look at stormwater. Like wastewater, stormwater can be evaluated largely by the source of its flow, but unlike wastewater, stormwater can also be evaluated by where it is getting discharged from the pump station. First, let’s look at stormwater as it relates to its source.

Wastewater and Pump Station Engineering

Romtec Utilities designs site-specific pump and lift station systems for every type of water. In the pumping industry, we typically define water types as fitting into wastewater, stormwater, industrial water, or clean water, but these are very broad and inexact terms. Romtec Utilities begins each pump station design by asking about what type of water is being pumped. Knowing the sources and conditions of the water ensures that a new pump station design will perform correctly for a long time. In this week’s blog, we will look at wastewater.

The Benefits of Drop Bowls and Deflector Panels

Romtec Utilities frequently includes drop bowls or deflector panels into wastewater lift station designs. These simple devices improve the function of the wet well and protect key lift station components from wear. Some customers, however, are not familiar with these devices. Drop bowls and deflector panels serve several important functions such as preventing cascading water, reducing turbulence, and redirecting solids.

Search for Romtec Utilities Projects by “Skid-Mounted Systems”

Romtec Utilities is always working to provide new and useful web content for our visitors and customers, and one of these new features is the ability to search projects as skid-mounted systems. These are complete pump stations that are mounted on prefabricated steel “skids,” so the pump station can be mobile, surface mounted, or used to retrofit an existing sump.

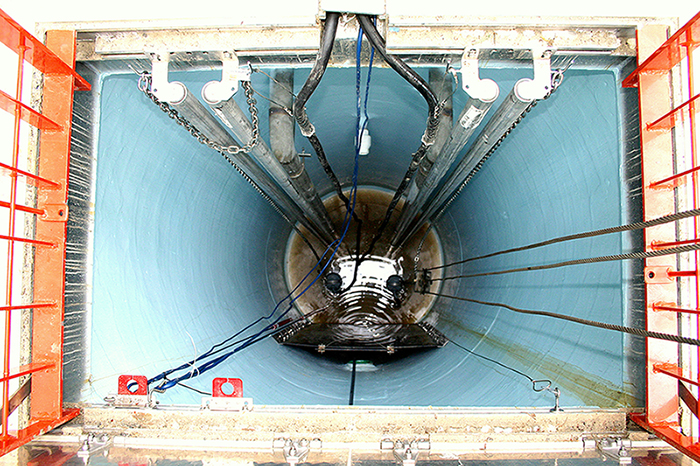

Components that Should and Should Not Go in a Wet Well

Romtec Utilities typically tries to reduce the amount of components located in the wet well on new lift station designs. Keeping the wet well clear from too many components will decrease maintenance concerns and improve the functionality of the system, but there are some components that will improve the wet well functions when included. In a lift station design for wastewater, it is important to understand what components to include in the wet well or not.