In frequent scenarios, lift stations are subjected to varying peaks of inflowing water and wastewater. There are different reasons for why these varying flow rates occur, but one simple and widespread solution is the overflow tank. Romtec Utilities works with customers to find the best approach for their project to select and purchase an appropriate overflow tank.

Jockey Pumps in Pump Station Design

Romtec Utilities designs pumps stations with jockey pumps for every major water type –wastewater, stormwater, industrial water, & clean water. Jockey pumps in pump stations are small, typically low horsepower, pumps that operate regularly to handle nuisance flows in a system designed for larger peak pumping rates. This allows the pump station to handle a very wide range of flow rates without increasing the wear on the large horsepower pumps.

Interior and Exterior Wet Well Coatings and Linings for Precast Concrete

Precast concrete components, such as wet wells or manholes, have the potential to encounter corrosive elements in water. There are several methods of protecting concrete components for particular site specific conditions. Corrosive elements are typically known when dealing with a specific water type or circumstance. Hydrogen Sulfide is typically a byproduct in wastewater –especially in hotter climates, while industrial water processing can be caustic or acidic. All of these instances can severely shorten the life cycle for concrete components if the concrete is not protected.

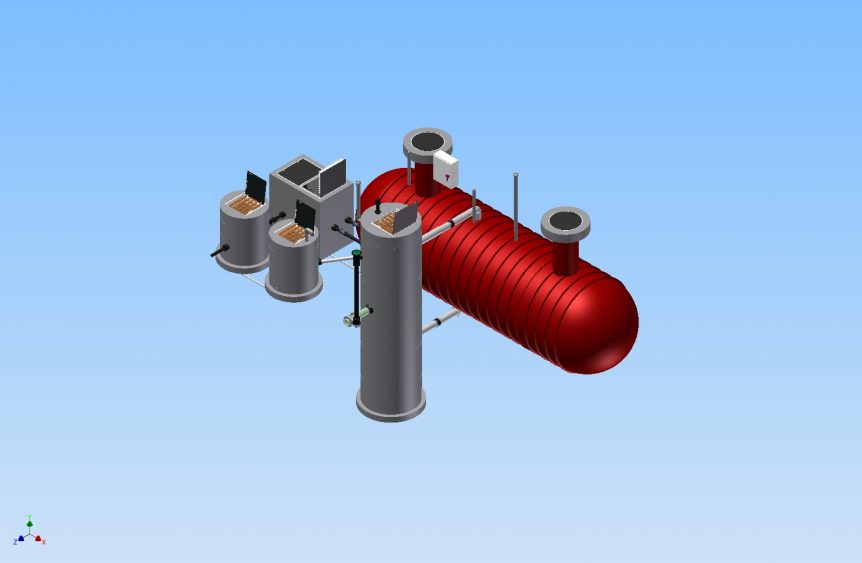

Double-Wall Fiberglass Sumps with Leak Detection

Romtec Utilities designs pump and lift station systems with true double-wall sumps and leak detection, sometimes known as secondary containment tanks. Lift stations with these sumps are extremely robust and are suitable for hazardous water types, corrosive liquids, and regulated environmental locations. Romtec Utilities has worked on several recent projects that required double-wall wet wells and suggests this type of wet well structure for any environmentally sensitive liquids or other sensitive water containment requirements.

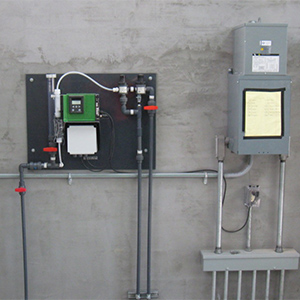

Passive Odor Control vs. Chemical Feed Systems

Romtec Utilities designs many different types of odor control systems for wastewater lift stations. Although there are a lot of odor control technologies available, there are two main thoughts behind odor control for wastewater. The first thought is referred to at Romtec Utilities as “passive odor control.” The second thought is referred to as “chemical feed systems.”