Romtec Utilities designs pump and lift station systems with true double-wall fiberglass sumps and leak detection, sometimes known as secondary containment tanks. Lift stations with these sumps are extremely robust and are suitable for hazardous water types, corrosive liquids, and regulated environmental locations. Romtec Utilities has worked on several recent projects that required double-wall wet wells and suggests this type of wet well structure for any environmentally sensitive liquids or other sensitive water containment requirements.

Romtec Utilities designs pump and lift station systems with true double-wall fiberglass sumps and leak detection, sometimes known as secondary containment tanks. Lift stations with these sumps are extremely robust and are suitable for hazardous water types, corrosive liquids, and regulated environmental locations. Romtec Utilities has worked on several recent projects that required double-wall wet wells and suggests this type of wet well structure for any environmentally sensitive liquids or other sensitive water containment requirements.

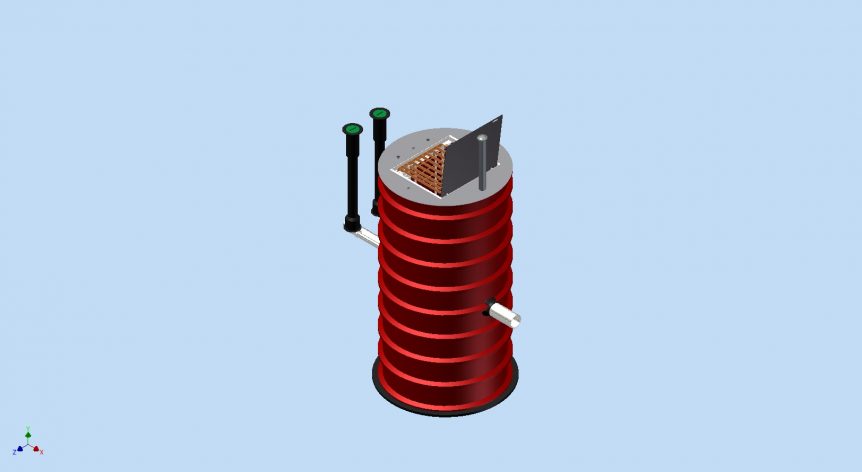

Romtec Utilities will typically design double-wall lift station sumps with prefabricated fiberglass basins. For these sumps, there are two walls to the basin with an “interstitial layer” that is vacuum sealed between the walls. This center layer is an entirely different fiberglass material that acts as a small perpendicular substructure which separates the double-walls with a gap, while maintaining the overall structural integrity of the sump. The small gap between the walls is what makes these components true double-wall sumps.

Leak Detection in Double-Wall Fiberglass Sumps

The continuous leak detection works by filling the gap between the sump walls with a control liquid that is vacuum sealed. In a reservoir at the top of the tank, a probe measures the elevation of this interstitial liquid. Any change in the level of the control liquid indicates that fluids are either entering or exiting the gap, detecting a leak. The probe can also measure the rate of the leak as well as trigger an indicating alarm.

The other common method of leak detection in double-wall fiberglass wet wells (secondary containment tanks) is much simpler. An electric sensor is placed at the lowest point of the wet well in the interstitial layer. When liquid leaks out of the primary wall, the liquid flows to the lowest point and activates the sensor.

Although this second method is simpler, it has a few drawbacks that can make it unsuitable for some applications. First, this sensor only detects leaks into the interstitial layer. A leak could potentially exist undetected if no liquid passes through it. Depending on the presence of gasses or other conditions, a leak could be harmful even without a fluid leak. The second drawback is that it places an electric sensor in potential contact with the liquid. Flammable or otherwise volatile liquids maybe be explosive when exposed to specific currents of electricity, taking this option potentially off the table for some applications.

Kensington Ohio Double-Wall Fiberglass Pumping System

Double-wall fiberglass tanks can be applied to many pumping system types. Romtec Utilities provided a stormwater pumping system to Utica East Ohio Midstream at their Kensington Plant in Ohio. As part of their commitment to the environment, Momentum Midstream needed to capture the stormwater at their natural gas plant. The stormwater could be contaminated with LNGs and therefore, it required double-wall fiberglass wet wells with interstitial leak detection and corrosion resistant components and sensors.

This relatively small stormwater pump station with 75 GPM and 67’ TDH, had a robust design due to the potentially caustic materials that it would be pumping. URS Corporation, the project engineer, made the design requirements clear to Romtec Utilities right away and our engineers were able to design and supply a lift station to meet all those requirements, including the double-walled fiberglass sump.

Industrial Fiberglass Wet Well Project

For an entirely different example of pumping system projects that require a double-wall fiberglass basin, there is the Naval Industrial Reserve Ordinance Plant project in Fridley, Minnesota.

The Naval Industrial Reserve Ordinance Plants, otherwise known as NIROP, was a weapons manufacturing plant from World War II. Due to improper waste disposal, the site suffers from Volatile Organic Compounds in the soil and has therefor been designated as a “Superfund” site by the Environmental Protection Agency.

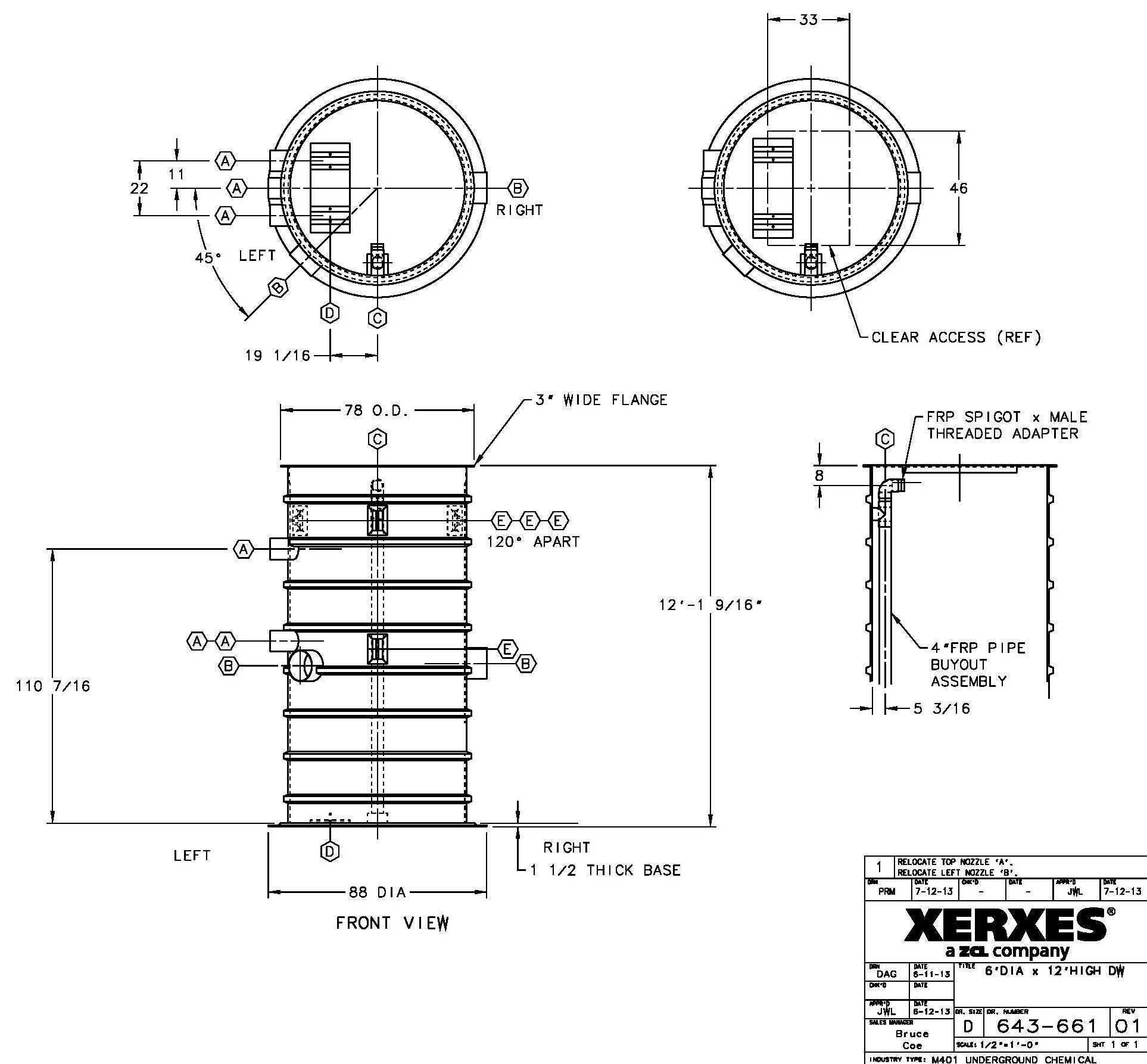

The “Superfund” designation is what put this facility in line for environmental clean up of which the Romtec Utilities pump station plays a role. This was the perfect application for the Xerxes fiberglass double-wall basin to house the VOC contaminated wastewater. This system consisted of a custom double-wall fiberglass wet well with 8’ inner diameter, an 8’ depth with 14 custom penetrations to receive the contaminated groundwater.

More and more projects with double-wall sumps are being developed by Romtec Utilities, using true double-wall sumps with leak detection. It is likely that this level of protection and sophistication will eventually be required for most hazardous fluid applications. Many industrial, military, petrochemical, and pharmaceutical sites are adopting lift stations with these components to provide the best in environmental protection, while some organizations simply want to avoid it being mandated in the future. Whatever the concern of your project, Romtec Utilities can provide the expert engineering necessary to give your project true double-wall sumps with continuous leak detection.

Comments 1

Have a chemical wastewater transfer project that requires secondary containment pump stations. Please send the specs for the product line and chemical resistance.. The wastewater pH varies between 2 and 14.

Thanks!

Nick