Romtec Utilities designs, manufactures, and supplies pumping systems for all types of applications, and at the heart of every pump stations is a similar goal: moving water. There are many technologies available for moving water in all types of different forms and conditions, and the best method is gravity, though it is not always available. Some project requirements specify the need to move a very high volume of water without generating a lot of pressure. This is typical in low land areas where flooding is probable during storm events, and damage from flooding is expected. Without a place to store or detain the water, it can be necessary to discharge water at high rates to a nearby place where gravity (by way of a creek, spillway, or other channel) can takeover. One of the best technologies for meeting these criteria is the axial flow pump.

Axial flow pumps excel at pumping high-flow rates of water at low to medium pressure. In these scenarios, axial flow pumps are the most efficient and affordable to operate. They accomplish this through the use of propellers. A centrifugal pump uses an impeller, which is designed to generate pressure differentials that cause flow. Propellers have pitched blades that can be adjusted to displace water at specific flow rates as opposed to generating pressure. This is what makes them more effective at handling high-flow requirements. The major drawback to a propeller versus an impeller is that propellers are in direct contact with the water being pumped. Any suspended solids in the water can damage or imbalance the propeller blades, negatively impacting the system performance.

Designing systems with axial flow pumps requires understanding the specific nature of the devices. In many cases, some form of screening or pretreatment may be required to ensure the water is free from solids. It may be necessary to also consider the system discharge point for adding riprap or a discharge structure. Since axial flow pump can discharge high volumes of water, forces like erosion can become an issue at the pump station discharge or in the downstream water system. Romtec Utilities will work with project site engineers to develop any structures required to prevent damage from the pump station discharge.

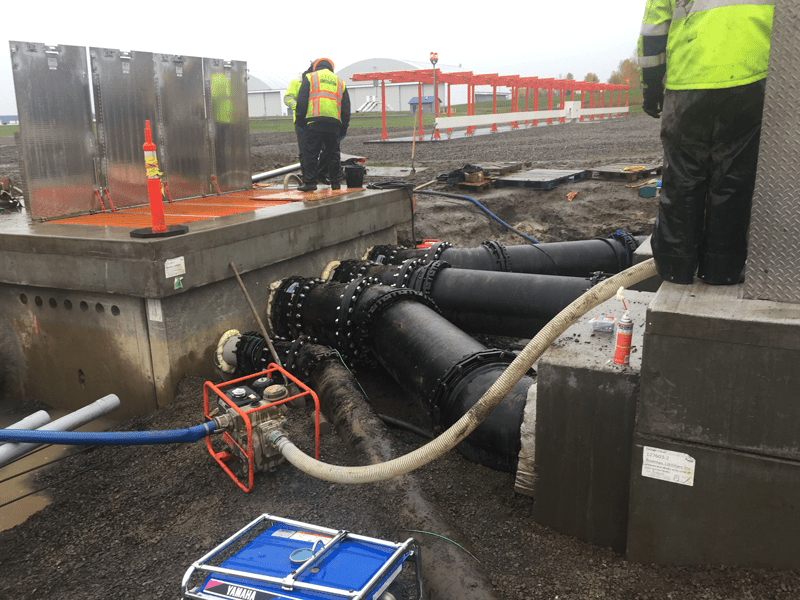

On a recent Romtec Utilities project, the Portland International Airport needed to pump stormwater away from runways. This scenario is referred to as a “no fail” pumping situation, meaning the pump station must pump in order for the site to be operable. Using axial flow pumps in a triplex configuration was the best way to achieve a “no fail” pumping solution. For this project, no other pump technology was reliable or powerful enough to ensure the uninterrupted use requirements for maintaining safe ground conditions at an international airport. Although axial flow pumps are sometimes thought of as a niche pump, much like Romtec Utilities, they are specialists that are extremely good at a specific type of work.

In the world of pumping, there are many considerations for the pumps. The primary thought will typically relate to meeting the flow requirements, but efficiency, power consumption, and design are all valid thoughts. On some projects, like at Portland International Airport, axial flow pumps are the pump technology that best provided a reliable design specification for meeting the project needs. Romtec Utilities uses all types of pumps to meet the goals of our customers. Contact our Sales Engineers today to learn about the pumps we can use and how our system designs will benefit your pumping project.