Romtec Utilities designs, engineers, and manufactures pump stations for many applications including wastewater, stormwater, and industrial applications. One challenge all pump station operators share is the risk of system failure, especially during extreme weather. Loss of power, component failure, and clogging/blockage are the most frequent causes for pump station failure during storm events. These types of failure can often be protected by including backup components, such as emergency generators or redundant pumping configurations. Redundancy helps to ensure your pump station and its service area does not suffer from a system failure with the pumps or control panel during extreme weather events.

Extreme weather can interfere with pump station operation in a number of ways. According to the Environmental Protection Agency, lift station mechanical or power failures cause approximately 10% of all sanitary sewer overflows in the United States. Many utility districts specify that new lift stations must include emergency backup generators because of this probability. Depending on the size of the generator and power needed to operate the pumps, generators may provide a reliable source of power throughout an entire storm event. Pre-storm preparation plans should always include checking fuel levels in the generator and refilling them as necessary. Generators are a great tool to ensure a pump station stays operational by providing redundancy to the power supply of the pump station and its controls.

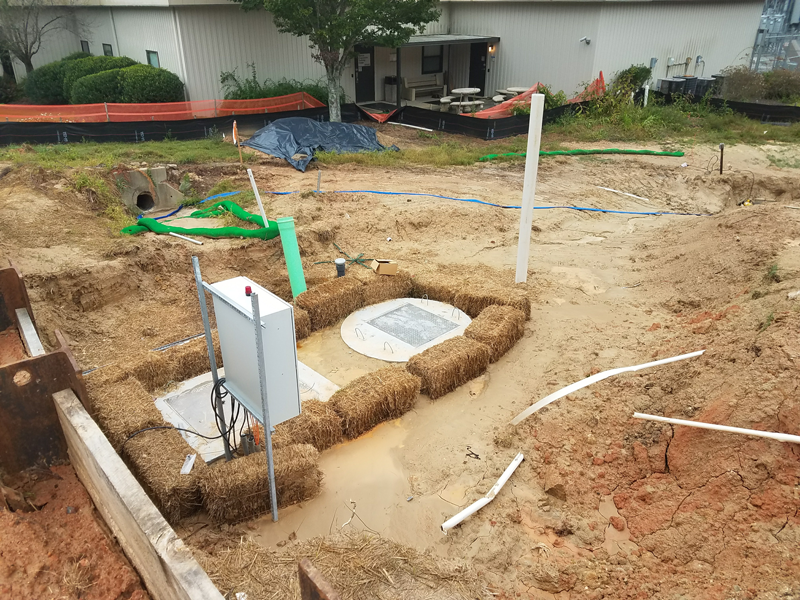

Redundancy in pump station design is beneficial for many aspects of the system. Lapses in service caused by pump downtime can often be avoided when 2 or more pumps are installed in redundant configurations. With stormwater, heavy flows of rain can stress pumps and carry large solids into the system, leading to possible malfunction. Redundancy provides secondary and even tertiary protection if one pump fails. Most Romtec Utilities pump stations include multiple points of redundancy for maximum protection. Other forms of redundancy for electrical controls include level sensing, controllers, and even remote monitoring telemetry. This provides pump station operators with management capabilities and real-time information on a pump station throughout a storm event.

Modern technology offers many advantages that were not always possible. In pump stations, remote monitoring technology, like a SCADA system, can be used to monitor the status of all pump stations in a service area. SCADA systems can be configured as simple monitoring systems or can be programmed to control pump stations remotely. Data gathered from the pump station can include flow rates, pressure, generator fuel levels, pump operation, in-well levels, and many other pieces of data. Operation personnel can use this information to diagnose and respond to many issues without having to travel to remote pumping sites. This is an easy and safer way to manage pumping systems during severe events.

There is no “one size fits all” solution to protecting pump stations from extreme weather. Different regions will experience different weather patterns and site-specific issues from local extreme weather events. Emergency power generators will always be an asset during powerful storms and are often required by local design standards. Including two or more pumps in a pump station will also fortify the pump station’s ability to provide continuous service during wet weather events. Other options for providing backup protections can be implemented through the electrical controls for the pump station by controlling systems remotely. Regardless of which backup protections your pump station requires, Romtec Utilities can design, engineer, and manufacture a pumping system to meet the unique requirements of your project. Contact Romtec Utilities for more information on emergency backup equipment and options today!