Romtec Utilities designs and supplies a wide range of pump station systems for all types of applications. One growing industry that needs new pumping systems is in the industrial and commercial sector for large stormwater pump stations. This sector includes new and existing plants and operating facilities that typically have a large building or property. With both a building or property, these facilities will almost always include large areas of impervious surfaces – areas where rain water cannot absorb into the ground. With large areas of impervious surfaces, this creates large amounts of stormwater runoff that increasing must be dealt with and will in most cases require some form of treatment prior to discharge. These large stormwater systems are important for industrial and commercial facilities to maintain a responsible level of environmental impact.

Large stormwater systems need to address a few design considerations up front. The first consideration is to address what happens to the site when significant rainfall occurs. In some locations, heavy rainfall means there is significant runoff which can pose a risk to surrounding waterways or the environment or may be mitigated by a detention pond. In other locations, heavy rainfall can flood buildings or equipment and cause significant or irreversible damage. Neither situation is ideal, but in the latter locations, stormwater pump stations must be designed to handle significant volumes of water without getting overcome or failing. This premise may sound obvious, but it can have far reaching impacts on the pump station design. Failsafe pump stations must take into account a lot of other considerations beyond the likelihood of flooding.

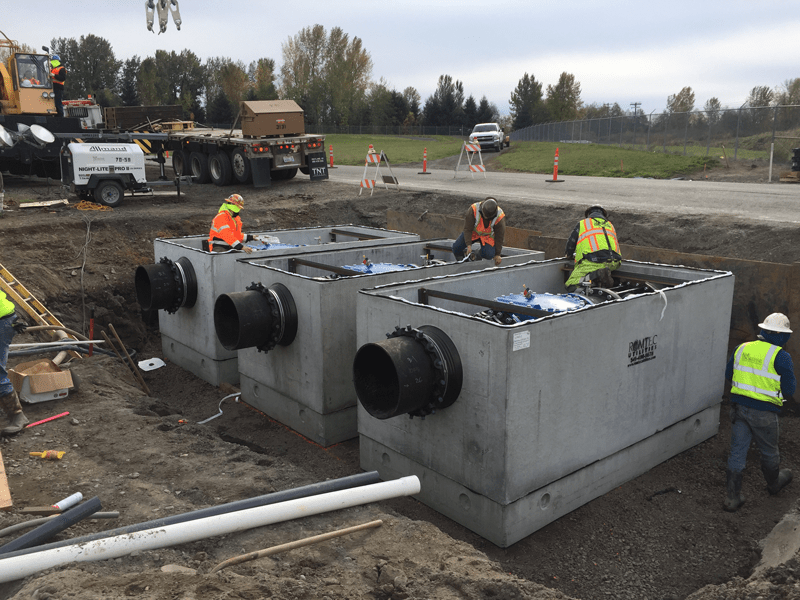

The next major consideration is the target flow rate and pumping rate of the system. The presence of solids, debris, or grit in the stormwater should also be addressed when considering flows. These two factors will help select appropriate pumps for the system. Two pump types that excel at moving high volumes of water are the vertical turbine pump and the axial flow pump. One design caveat with these pumps is that they cannot handle suspended solids. Often times, it is a better solution to add a prescreening structure to a large stormwater pump station than to compromise on the pumps. This will give the system better efficiency and less opportunity to fail. In areas where a failsafe system is not crucial, these types of solution may be well above and beyond what is necessary to handle the majority of stormwater scenarios, and another pump type may be acceptable.

Large stormwater pump stations can also include many additional systems and assemblies that play important roles for the system. Control buildings and shelters make useful additions for maintaining and operating these systems during sever weather. Intake structures, discharge structures, and riprap can be used to make sure that the stormwater is handled appropriately before and after entering the pumping system. Electrical controls, sensors, and communications can include multiple types of redundancy to make sure that the pump station stays operational even under difficult circumstances. In some scenarios, these devices can also shut down the system if the site floods. This can prevent burning out equipment and wasting resources. Auxiliary systems can be very important for large stormwater applications, so understanding the needs of the site and operations personnel can be very significant considerations through the system design.

Getting a large stormwater pump station may be a preventative consideration, or it may be imperative to the operation of the site. At large industrial and commercial facilities, these premises must be addressed to get the best system possible. Through understanding the dependence on the pump station, decisions about water, pumps, controls, and other assemblies can be made more easily. On many projects, large stormwater pump stations represent a move for commercial and industrial facilities to act responsibility toward the local environment. Romtec Utilities works through each project to make sure that the customer’s goals are always met.