Romtec Utilities pump stations are designed as site-specific systems based on the design criteria supplied by our customers. These engineered systems contain many individual components, including level sensors like conductive probes. This is the fifth installment of the Romtec Utilities blog series covering level sensor technologies commonly used in pump stations. Today, we’ll examine conductive probes. These level sensors have a simple functionality with reliable level sensing capabilities in many water chemistries.

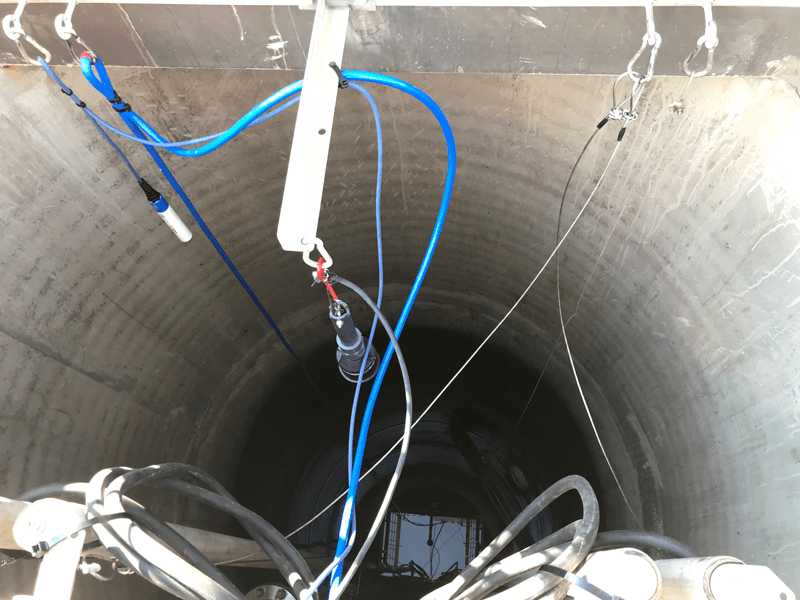

Conductive probes are simple and effective level sensors that are commonly employed in municipal wastewater applications. Probes are long cylindrical devices that have multiple points of contact for detecting fluid levels. When fluid makes contact with one of these points an electrical current passes through it to complete a circuit. This detection method is incredibly reliable with little to no room for false readings or errors. This process does require that the fluid being measured is able to conduct electricity. Distilled water, alcohol, and vinegar are a few examples of materials that cannot be detected with conductive probes for this reason. Conductive probes also are often times not able to be used when the fluids are flammable or explosive due to the direct exposure to electrical current, though it is typically too small to be dangerous.

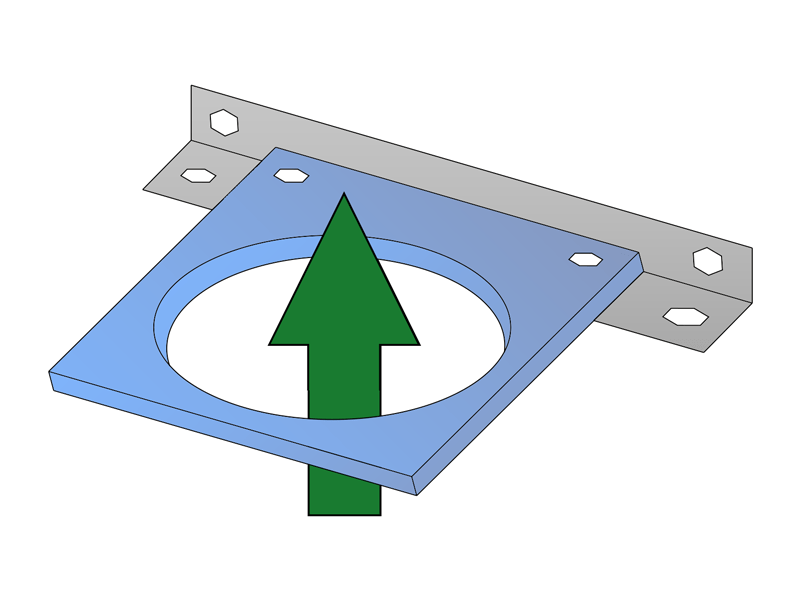

Their small margin for error makes conductive probes an excellent choice for backup level sensors in pump stations. Similar to mechanical floats, the lack of moving parts on these components mean there are fewer maintenance requirements. However, these sensors are prone to grease build-up, and solids like paper and cloth can sometimes wedge between the contacts, creating false readings. Level probes are frequently installed with special mounting brackets that make cleaning it off much simpler. Below are two pump station projects that make use of conductive probes for level sensing.

Pioneer Place Development – Residential Housing Development

The Pioneer Place housing development in Ridgefield, Washington required a new wastewater lift station in order to meet the expected sewage flows of the new houses. Romtec Utilities designed, supplied, and engineered multiple pump stations in this area and were familiar with the well-defined design standards of the water authority. One of these standards dictates using conductive probes on their medium sized lift stations as the secondary level sensing device. Probe sensors work well in this scenario due to their reliability, but they lack the precision of ultrasonic transducers which are used for communicating exact levels via SCADA. Conductive probes cannot be set to exact elevations and are fixed to the contact points for measuring levels.

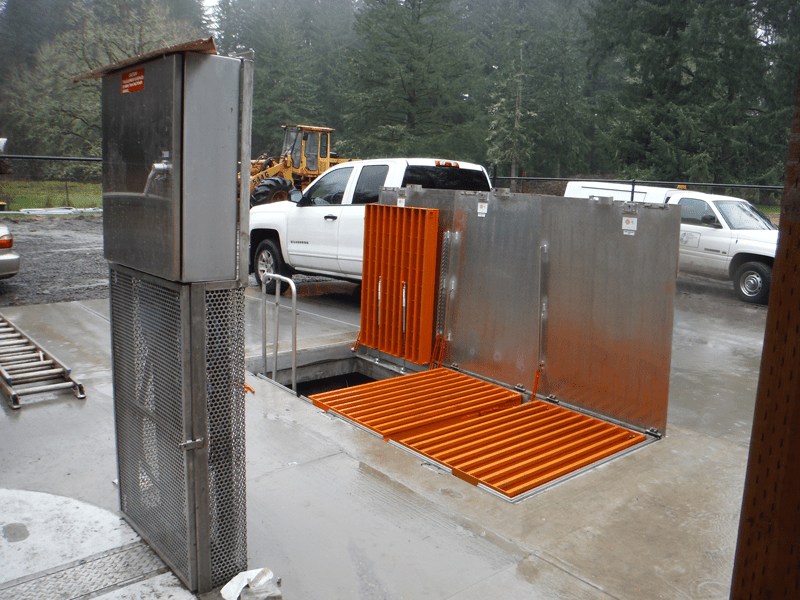

Back Nine Development – Industrial Development

The Back Nine industrial development in Roseburg, Oregon also makes use of these dynamic level sensors. Similar to the previous project, conductive probes were selected as the secondary level sensor to operate alongside an ultrasonic transducer. This pump station included a 22’ deep wet well and required 10-point conductive probes. Although some of these points are not used, the 10 point probe option allowed Romtec Utilities to configure many more actions at specific elevations than many other level sensors would have allowed. This customizability worked well in this powerful wastewater lift station application.

Conductive probes make an excellent backup level sensing option in many applications, but are primarily used in municipal wastewater systems. Their functionality requires water to make contact with one of the points on the sensor to allow an electrical current to pass through and complete a circuit. Minimal upkeep is necessary for probe sensors besides regularly cleaning off built-up grease, but certain hardware can make this task much simpler. Romtec Utilities can include conductive probes or any other style of level sensor to meet the measurement needs of your unique pump station project. Contact us today for more information on level sensors and how they can benefit your pump station design!