Romtec Utilities designs, supplies, and manufactures package pump stations that comprise many individual components selected for the specific application. One set of components found in every one of our pump stations are level sensors, like bubbler level sensors. This is the sixth and final addition to the Romtec Utilities blog series covering the different level sensors commonly used in our pump stations. Bubbler level sensors excel in providing continuous level measurements in applications where submerged sensors may be damaged. These devices are employed across many different industries and are favored by a select population of pump station operators familiar with them.

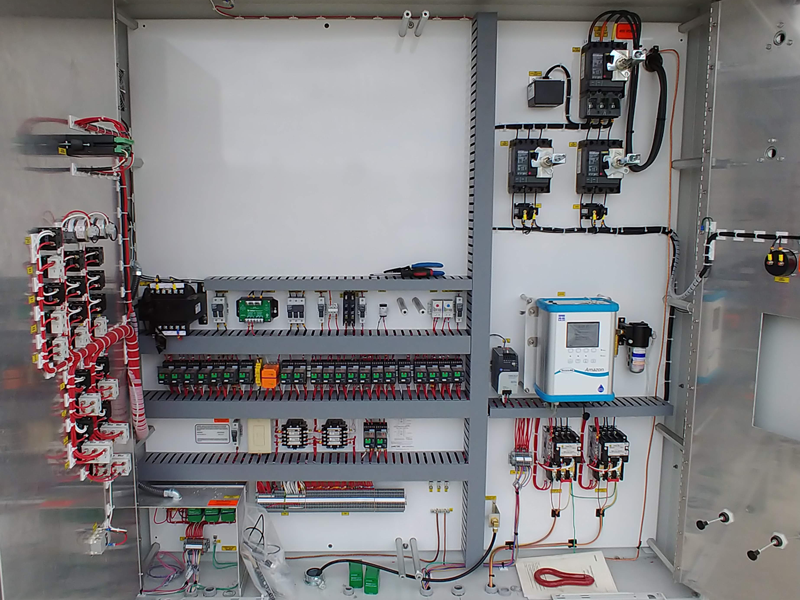

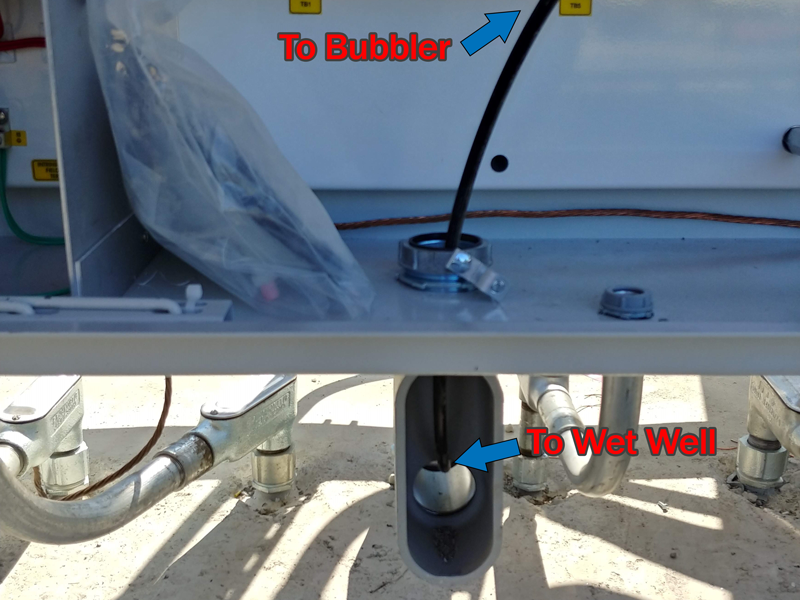

Bubbler level sensors are unique in their functionality, but share some similarities with other sensors. Real time active volumes are identified by releasing air bubbles from beneath the surface of the water and measuring the pressure of resistance. These devices do not need to be submerged in the water and instead send compressed air to the bottom of the tank through a tube. Bubbler sensors are excellent options in pumping applications for industrial process water, harsh chemicals, and other corrosive substances that can damage submerged sensors. Bubblers are often installed near the electrical controls for the rest of the system or in places that can easily be accessed by personnel.

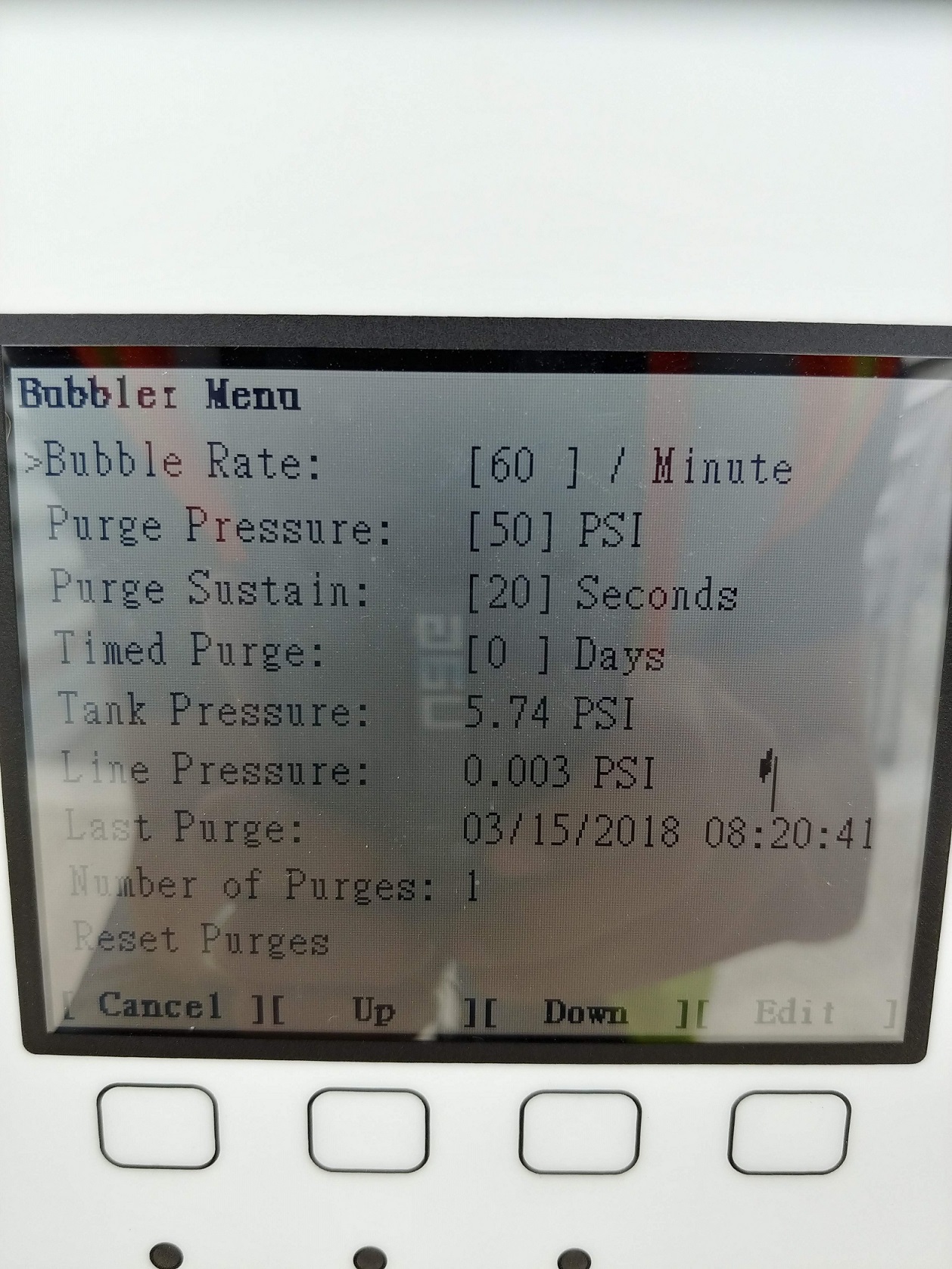

Unlike many other level sensors, bubblers can operate as stand-alone devices. Some models are available that include a graphical user interface (GUI) that allow pump station operators to see real time information about the system. This makes bubblers excellent for troubleshooting when an issue does occur with the system. Multiple communication ports are available, including USB and Ethernet connections for connecting computers and other devices. Bubblers are frequently connected to SCADA systems to allow remote monitoring of locations. Below is a project Romtec Utilities completed that included one of these sensors to meet the preferences of the owner.

City of Fife – Wastewater Lift Station

The construction of a new industrial plaza required the replacement of an existing wastewater lift station for the City of Fife, Washington. The new lift station is located less than 100’ from the existing system and was designed using site-specific data and the design standards of the municipality who would eventually own it. One of these standards dictated the use of an Amazon Bubbler as the primary level sensing device. The bubbler provides real time level sensing information and will require less maintenance than other sensors that would otherwise be installed submerged in the corrosive wastewater handled by the lift station.

Bubbler level sensors make great continuous level measurement devices for pump stations and many other industries. These devices are not submerged and are advantageous in applications handling corrosive water and other harsh conditions in the sump. Romtec Utilities does not encounter many of these sensors in our pump stations, but can and will include them or any other preferred brand or style of level sensor. Contact Romtec Utilities today for more information about bubbler level sensors and pump station design!