“Prefabricated Mold for Saving Time On Site”

The Portland International Airport (PDX) Terminal Core Redevelopment project was brought to Romtec Utilities by Coffman Excavation. The original plan for this wastewater pumping system was to be a cast in place structure, but, having worked with Romtec Utilities in the past on projects utilizing pre-cast structures, Coffman and their General Contractor, Hoffman Skanska, contacted Romtec Utilities for our assistance on this project.

In a previous Port of Portland project, called the “PACR” project, Romtec Utilities supplied Coffman with two pre-cast stormwater wet well systems and a pre-cast wastewater system. In the Portland International Airport (PDX) Terminal Core Redevelopment project or “PDX TCore” project, Romtec Utilities would be working with the same entities, Coffman Excavation, Hoffman Skanska, and the Port of Portland. The scale of the project and the opportunity to work with repeat customers made Romtec Utilities eager to be a part of this project.

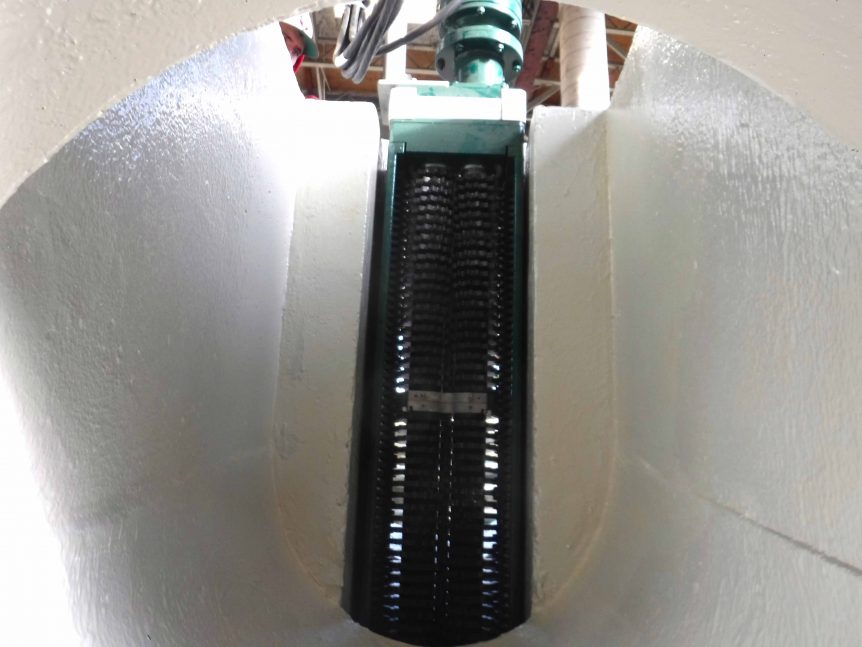

The “PDX TCore” project is notable for many reasons, including the addition of two inline, gravity fed “Muffin Monsters” that pose some unique challenges for construction. A “Muffin Monster” is a macerator that wastewater will pass through in order to break down and reduce the number of solids before entering a lift station. Produced by JWC Environmental, these grinders are designed to cut down the solid wastes that may be in the water.

Solids in the wastewater can cause damage to systems, especially if they are particularly large or if they are not water soluble, meaning they won’t break down as they sit in the water. Clumps and solids are a real issue when it comes to wastewater pumping, and the Muffin Monster can eliminate those problems and cut down on costly maintenance and repairs that lift stations may require. Many things can cause clogs or damage to a pumping system, including but not limited to oils, fats, solid waste, and wet wipes and other hygiene products.

Muffin Monsters can be used in many applications, including airports, corrections, food waste management, and more. JWC has a range of Muffin Monsters and related products to suit any customers wastewater needs, and tout a reliability of 45+ years. All of this information and more can be found at the following link.

While the addition of a Muffin Monster may help to lengthen the life of the lift station, they also pose an obstacle for construction. Traditionally, Muffin Monsters in the gravity flow line require a specific channel mold that needs to be poured on site. Most commonly, the grinders are plumbed directly in line with the piping with a bypass around the grinder, if necessary. This method requires extra materials, extra time, extra work for the contractor, and has the disadvantage of inaccessibility and a large footprint for the vault the grinder and piping would require.

Romtec Utilities looks for opportunities to prefabricate components and minimize construction time on site. Romtec Utilities experts were able to design a pre-fabricated mold that places the Muffin Monster into a manhole, a novel idea that may not have been considered or used in the past. This custom, pre-fabricated basin has many benefits, such as ease of installation and a small overall footprint. The grinders will be set right into the concrete “slot”. Inside the channel, the Muffin Monster will sit on guide rails to allow for easy lifting of the Muffin Monster for maintenance and ease of access.

The grinders at the PDX TCore project are different sizes, and would ordinarily all require custom molds to be poured on site. Romtec Utilities created forms for each grinder to ensure that each grinder will fit properly in place and be able to function properly.

In addition to eliminating the need for on-site pouring, this pre-cast method has the added benefit of being able to do any prep-work and quality control checks at Romtec Utilities Production Facilities. While the pre-cast molds were at Romtec Utilities production facilities, production specialists also coated the interior of the molds with an epoxy coating. The coating Romtec Utilities uses will provide little resistance to the wastewater as it flows through, as well as protect and extend the life of the concrete. This will ensure that the Port of Portland is getting the best product while cutting down on the work that is needed at the construction location.

One of Romtec Utilities’ goals is to streamline the construction process to create not only a faster but a more efficient installation of our structures. The use of the pre-fabricated mold and placing the Muffin Monster into a manhole will dramatically cut down on the time and work needed on site for the “PDX TCore” project.

Romtec Utilities works hard to bring the best minds in house to design and supply these lift station systems; our engineers are exceptionally knowledgeable and innovative, allowing Romtec Utilities to problem solve and do what it takes to please our customers. This expertise and experience provides our customers with the best possible system for their needs, making Romtec Utilities lift stations the best investment for safely handling waste laden water.

The “PDX TCore” project is a large project encompassing a great deal of engineering and construction. The project has yet to be completed, but Romtec Utilities and everyone involved is lending their knowledge and experience to ensure the greatest success for the project.

Romtec Utilities would like to thank Coffman Excavation for the opportunity to lend our experience and expertise to Hoffman-Skanska, HNTB, and the Port of Portland, who will own this system after the start-up. We would also like to express our appreciation to JWC Environmental, and Dennis Birgen and Patricia Loo from JWC for their assistance on this project.