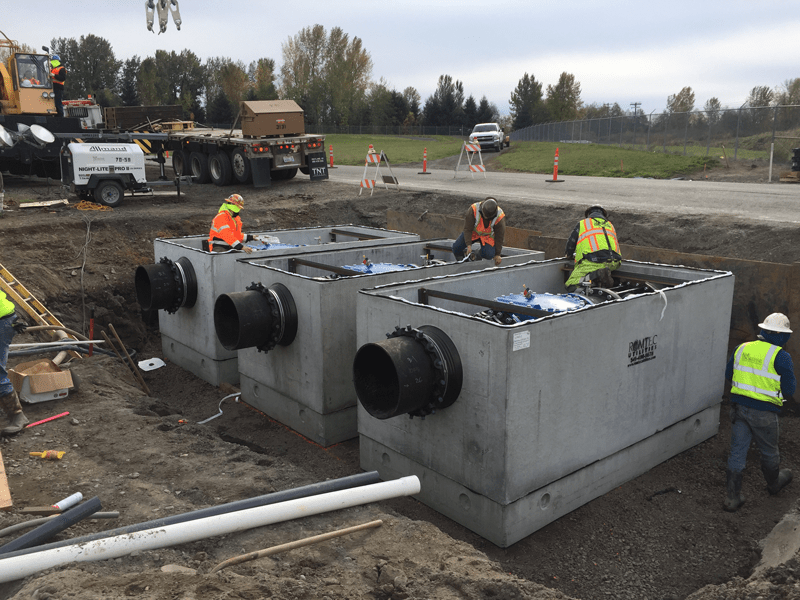

Romtec Utilities is an industry expert for designing pump and lift station systems in all types of applications, including municipal and private projects. In addition to our design expertise, Romtec Utilities offers clients another distinct advantage when purchasing a pumping system: prefabricated assemblies. One key feature of prefabrication is the coring of well and vault penetrations. By pre-coring the system penetrations, Romtec Utilities helps our customers get through the pump station construction quickly.

You might wonder what coring is and why it is important, and the answer is fairly simple. Coring is the process of cutting penetrations (or holes in plain English) into a structural vault, well, or tank. These penetrations are where piping and/or conduit enter and exit the structure. Coring is virtually always performed on precast concrete even though penetrations can be cast into place. Coring helps save time and money because components can be cast in larger batches with less setup and preparation. As such, these structural components can be manufactured faster and are more economical to purchase. In the old ways of completing pump stations, there were two typical options for coring the concrete components.

The first option is to have the precaster core the penetrations after the concrete is cured and before it is shipped to the contractor. Engineers provide production drawings to the precaster with the core locations specified. Then the precaster cores the holes per the drawings, and this usually incurs a per core fee that increases with the diameter of the penetration. The potential issue with this is that there can be misunderstanding between production drawings, the precaster, and the contractor. Once the penetrations are cored, anything incorrect will have to be patched, which can compromise the system, or remanufactured, which can delay the project.

The second option is that the contractor receives the concrete components and then measures and cores the penetrations at the job site. This can be problematic because job sites are not controlled environments, and conditions such as level ground, weather, and equipment can impact the ability to properly core a penetration. Additionally, some contractors may not own the proper equipment to core penetrations in the field. In these circumstances, there are vendors who can provide coring services, but depending on the location and number of penetrations, these services can add a lot of cost to project. This option can also be prone to mistakes through miscommunication or a misunderstanding of the plans.

Romtec Utilities favors precoring penetrations and preassembling many aspects of the pumping system. As the designer, engineer, and manufacturer of the pumping system, Romtec Utilities virtually never makes a mistake related to locating and coring penetrations. Our systems cover all of the preassembly work, so coring is not added charge to our typical manufacturing labor. With all of the penetrations cored, the components can be delivered to the jobsite ready for installation. This helps the installation process move faster and prevents mistakes related to penetrations that can set back timelines significantly.

Coring penetrations is necessary on most pump stations where precast concrete is used for the pump station structural components. By having this work completed by Romtec Utilities, our customers experience a much more tightly controlled and supervised process. This reliably provides the correctly located penetrations when the system is delivered for construction and installation. Using Romtec Utilities for our prefabrication and preassembly work is a great way to get a fully functional pump station without many of the typical hassles that can be associated with the concrete structures. Call Romtec Utilities today to learn more about our services!