A New Large, Robust, and Safe Booster Pump Station at Sumner Ridge

Romtec Utilities engineers pumping systems for all types of applications, including this new underground booster pump station that maintain water supply pressure. Booster pump stations can vary greatly in size and capabilities, and we have completed projects that run the spectrum from small to large. This recent project was for a sophisticated underground booster pump station that maintains water pressure and supplies fire suppression systems at two new industrial warehouses as part of a land development project in Sumner, Washington. The completion of this project was deemed essential to pandemic recovery, and Romtec Utilities completed the full supply and commissioning of the system.

This booster pump station project was one aspect of the Sumner Ridge Development funded by Bertch Capital Partners. Since the development included two large industrial warehouses, space on the site was limited. The best place for locating a booster pump station was below-grade in a vault structure. Romtec Utilities offers experience constructing large, cost-effective in-ground structures from precast concrete. In addition to the economic value, using precast concrete for the booster pump station structure allowed many aspects of the final system to be prefabricated and quality controlled prior to delivery and installation. This work saved the developer time during installation.

Not every aspect of the system was constructed below-grade. Romtec also supplied and constructed a control building for this booster pump station to house a large MCC panel with a sophisticated Allen Bradley PLC for the system controls. For this privately owned and operated system, this control configuration offers robust controls, advanced monitoring, and ease of use for management personnel. As mentioned, space was limited, and Romtec Utilities was able to meet the goals of the developer by orienting the below and above grade systems in a small space on the site.

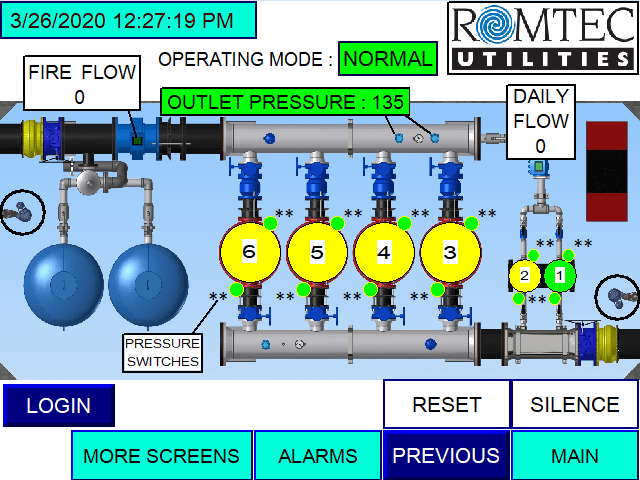

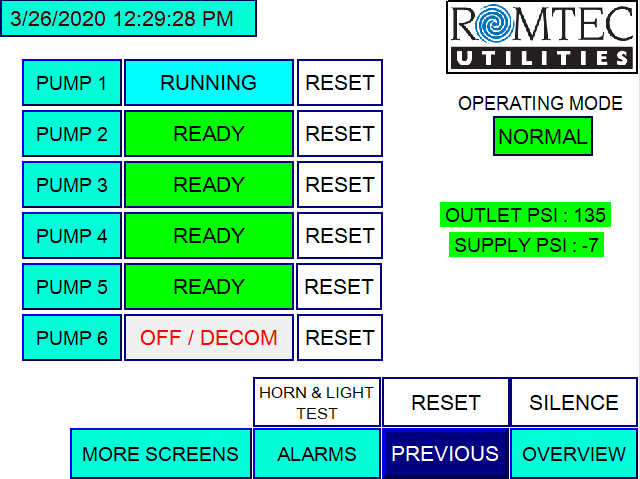

This system includes 6 total pumps for the booster station. Only two pumps are required for daily flows, per the design, and as needs increase, more pumps will start in order to meet the maximum pressure requirements, which included full fire suppression to both warehouses. There are two flow meters on this system for redundant flow monitoring. Having two meters would allow for accurate tracking of water usage at the facility from the domestic water supply and total water use for other applications like fire suppression. The system controls use a cellular autodialer capable of text and email system notifications. Flashing lights and alarms function in the vault provide operations personnel local feedback during maintenance or other work on-site.

Romtec Utilities created these digital control interfaces for use on the PLC panel through a touchscreen interface. These interfaces provide easy to read and operate controls for typical and in-depth system reports and monitoring.

In addition to the dependable electrical controls, this booster pump station includes safety features for both the system operators and the system equipment. The vault portion of the system includes multiple ladders for both entry and exit safety in emergency conditions. It also includes an industrial dehumidifier, flood sensors, and dual sump pumps to protect the system from water incursion or other potential sources of flooding. An air exchange system keeps the below-grade atmosphere safe, and it can be initiated by opening the vault hatches or by manually turning it on and off at need. All the major electrical components in the vault (pumps, dehumidifier, and other high load components) include individual electrical disconnects providing operators a local disconnect to cut power to a component without needing to access the control panel.

Romtec Utilities worked with the developer in Bertch Capital Partners, the project GC in Sierra Construction Company, the installing contractor in Miles Resources, and the project engineer in Barghausen to complete this booster pump stations project. Utilizing expertise through structural, mechanical, electrical, and communications systems, Romtec Utilities provided a reliable booster pump station that meets the specific needs of this industrial development site. Our configurations provided a reliable system that is safe, easy to use, and economically configured. Additionally, prefabrication work on the booster pump station and turnkey construction on the control building helped this project complete in great speed.