Romtec Utilities designs, supplies, and installs pumping systems in a wide variety of applications. Each system we engineer is site-specific and meets criteria that is unique to that site and operation requirements. At the center of each system is a calculation that is used on every single project to determine the Total Dynamic Head, or TDH, of the system. The TDH describes many different variables as a single number that can be used to engineer pump stations with respect to the desired pumping rate of the system. That is a good piece of data to begin with on any system design.

The premise behind determining the pumping rate is simple. Each pump station has a certain amount of inflow and an economical amount of storage volume. These two pieces of data let the civil engineers or Romtec Utilities engineers determine a peak pumping rate. This number assumes that if the pump station experiences the most severe inflow conditions possible, the pumps will be able to pump out the water without starting too many times per minute and without accumulating too high of a storage volume. This number becomes the peak pumping rate and is where we begin the actual TDH calculation.

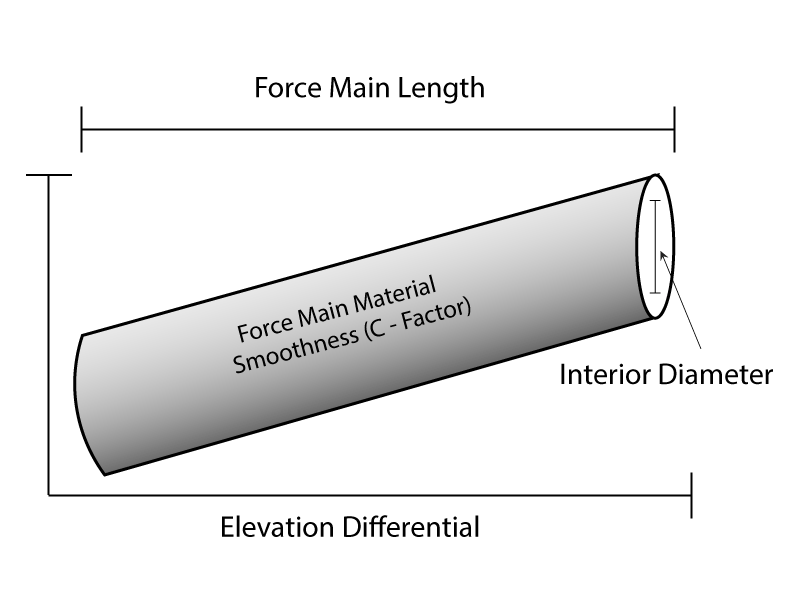

The peak pumping rate has some variability to its determination because different jurisdictions maintain different requirements called peaking factors; however, after the peak pumping rate, aspects of the TDH calculation become a little more concrete. The next pieces of data required are related to the force main piping. The key information here is the internal diameter of the force main, the length of the force main, the elevation differential of the force main, and the piping C-factor. In the case that the force main is a new construction with the pumping system, these pieces of data all need to be determined before TDH can be calculated. Making changes to the force main design after the TDH is calculated can lead to expensive design changes.

To unpack this data, we can take a quick look at each piece of information. The force main ID (internal diameter) determines the volume of water in the pipe over a certain distance. The force main length also is an important aspect of that. The elevation differential determines the effect that gravity will play on the volume of water in the force main. As the elevation between the pumps and the discharge point increases, the pressure in the force main also increases as a result of overcoming the force of gravity. The final piece of data is described as the pipe C-factor, where C means coefficient of friction. A bigger C-Factor indicates a smoother pipe surface. Piping like PVC is smooth and has a C-Factor of about 150, while cement lined ductile iron pipe has a C-factor of 120. This number indicates the friction water will experience while moving through the force main, which increases pressure and TDH.

Using this data together, the most typical calculation is the Hazen-Williams equation. This calculation assumes some basic information like average temperatures, consistent gravity, and typical water viscosity. In more extreme ranges of pumping applications, a different TDH calculation is likely more appropriate, but the Hazen-Williams equation is very reliable for the vast majority of pumping systems.

Romtec Utilities works with project site civil engineers to specify the data needed to calculate TDH before a pumping system is engineered. The single TDH number is used to accurately size pumps and determine many other aspects of the system design. Our engineers employ expertise from all types of disciplines to make sure that you get the best pump station for your project with all structural, mechanical, electrical, and communications systems included. Contact Romtec Utilities today to learn more about out pumping systems and how our teams can help you on your next project!