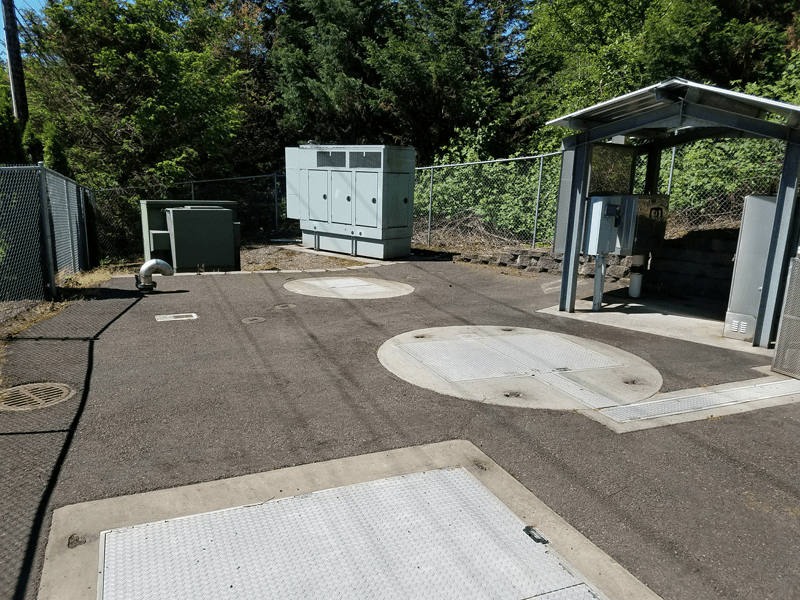

Romtec Utilities designs, manufactures, and supplies pump stations for many applications with all structural, all mechanical, all electrical, and all communications systems included. Every pumping system designed by Romtec Utilities is specific to a site and its specific pumping requirements. This is the best practice for a good pump station design to get the best equipment and the longest life from your system. Large construction projects, however, can be ongoing for many years, and as construction phases are completed, the pumping requirements of the site can change. Outside of large construction projects, the public sector can also experience expanding residential and commercial districts that can changing pumping requirements. Although no one has a crystal ball, planning for the future is a savvy thought for any pump station project.

Most commonly, planning for the future of a pumping system is related to increases in flow rates. For wastewater lift stations, there are standard calculations for all types of construction, like residential, commercial, and others. For example, the nominal wastewater flow for an average house is about 350 gallons per day. If you know how much new construction will be added, you can calculate the future needs of a lift station. For stormwater, it is typical to consider average annual rainfall and other statistics to size the future needs of a pumping system. Like wastewater, this planning is typically related to future construction project that will flow into the new pump station. In clean water and industrial applications, the pumping requirements tend to be very consistent year after year, but planned upgrades or expansions can also be typical and require future planning in the system design.

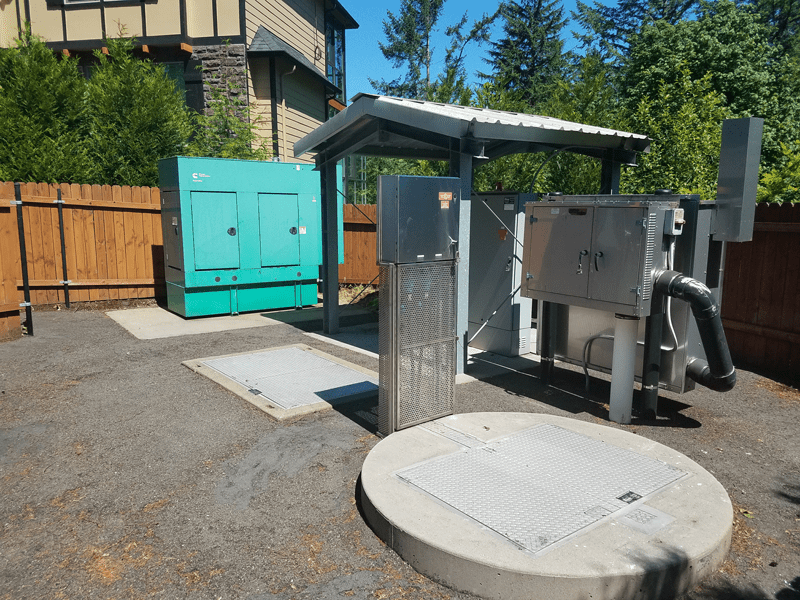

Planning for future changes to the pumping rate can have far-reaching implications on the pump station design. This can be as straightforward as designing the system to include an additional pump in the future, but in some cases, choosing to upgrade to higher horsepower pumps is a better path. In this case, the control panel, discharge elbows, piping, and valves can all be implicated by the future pump selection. Recently a residential neighborhood’s lift station was retrofitted with more powerful pumps and electrical controls to keep up with growing sewer flows. If the future design is known, all of these elements can be accounted for to make a pump upgrade an easy process when the time comes. Conversely, upgrading pumps with no plan or advanced design work can cause a major headache.

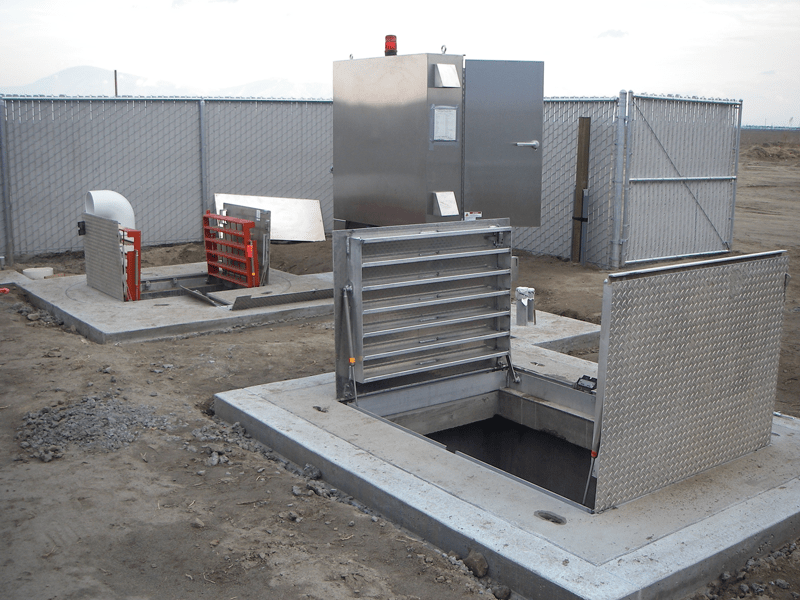

Although a high number of pump stations plan for changes in the pumping rate, there are other changing conditions that can be planned for in the design. Electrical power supply is one aspect of a pump station design that can change over time and that can be a good consideration. Often times this includes upgrading from a single-phase power supply to three-phase. Pump stations can also account for future requirements for valve, metering, and bypass vault assemblies. Understanding how the electrical controls, vaults, site restrictions, and other factors are impacted by a new mechanical assembly will help develop a good pump station design for the immediate and future needs.

Future planning for pump station designs can be shrewd and even necessary in any type of application. Romtec Utilities has worked on numerous projects at all stages of this process. The best solution is to account for the expected future changes for your system by including design considerations that will facilitate the appropriate upgrades. To learn more about pump station designs and future planning, contact our sales team today and learn about how Romtec Utilities can help get you the pump station you need now and in the future.